As a new discovery, this high initial step-over can cause parts of the pocket to not get machined.

If the stepover is more than half the width of the bit (perhaps not the best practice, but still a valid thing to do), you can have material left behind. Since the initial stepover can be double the requested stepover, and the stepover is more than 1/2 the bit diameter, as a worst case scenario the initial stepover is more than the width of the bit.

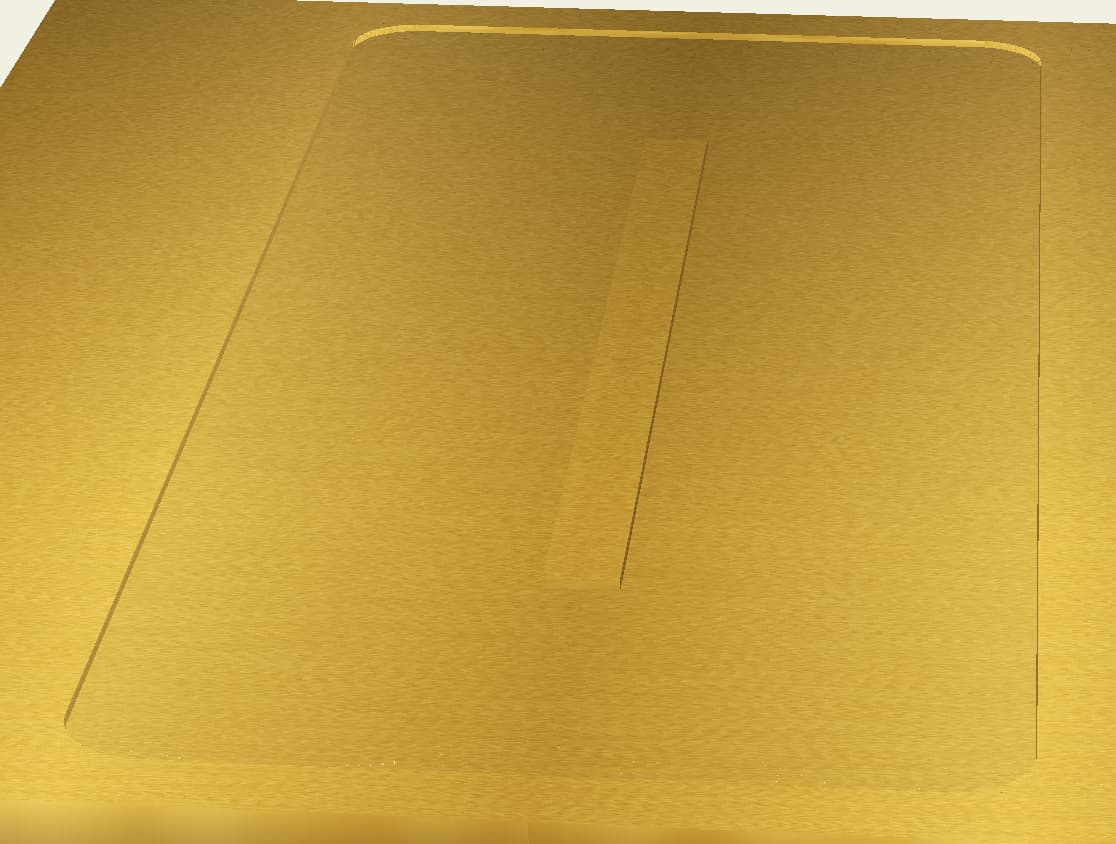

An exaggerated example - 3/4" bit, 14mm stepover:

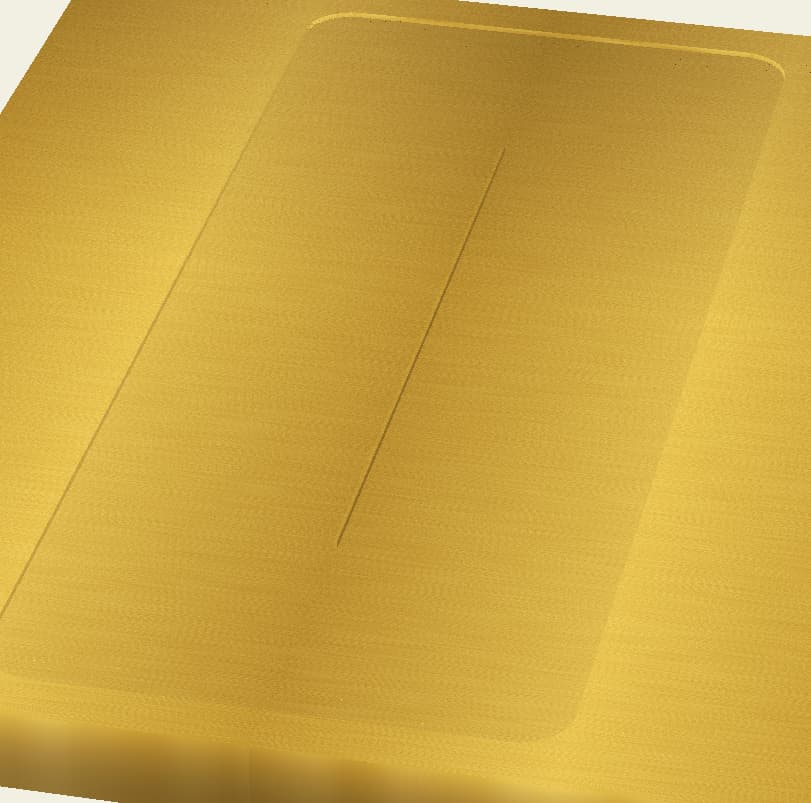

But even with a not-unreasonable sounding 3/4" bit, 10mm stepover: