In this 2nd

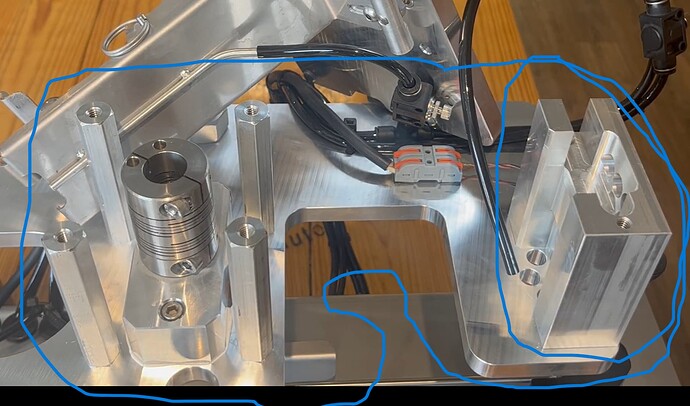

pic, I’m talking about the vertical bar part. It’s probably 4" tall, 3" deep, and 2-3" diameter. Max.

I don’t see why not. As long as the part will fit in the 27"x21"x6" envelope & you have adequate workholding. I would recommend coolant, like a mist system.

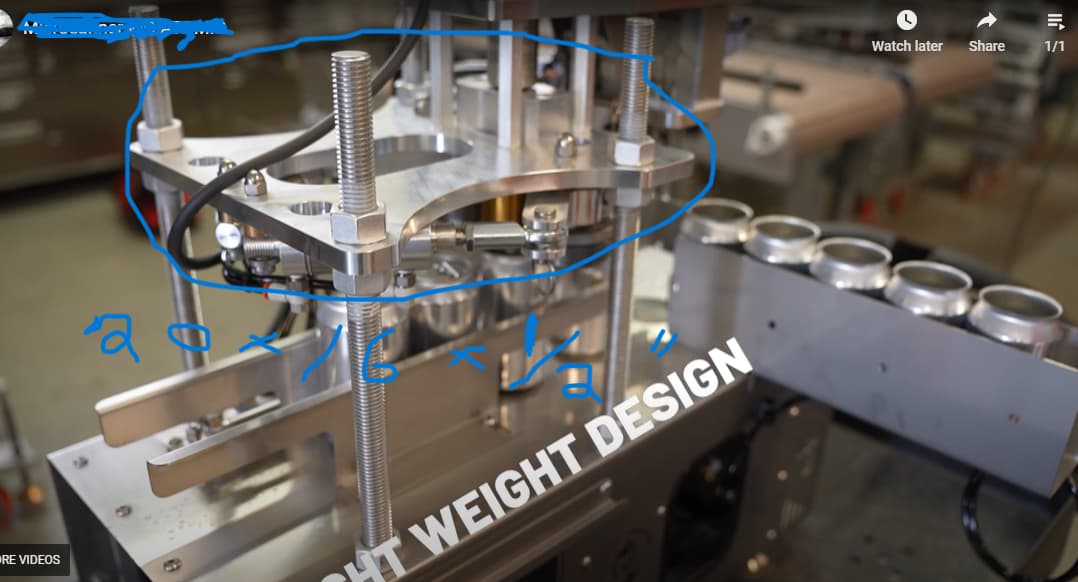

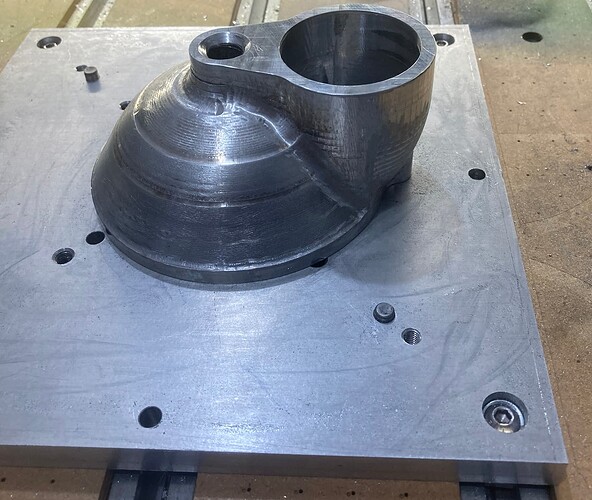

Here’s some aluminum parts I’ve made.

Wow, those look fantastic! Great job! In the 3rd photo did you use the HDM to make those threads also?

All those parts are aluminum correct?

That is very nice work @Tod1d. I really like the clean lines of the impeller. Recently, I was considering using two-sided milling for a project but your IMG_1140_sm suggested to me that I could potentially make the project (an aluminium chess set) in identical halves. What was the grade of aluminium that you were using for your parts? I find that I like the workability, machinability and the strength of T6 materials like 6061.

Thanks. It’s all 6061 T6, except the oil cooler bell housing, which you can see the finish isn’t quite what I would have liked. Fully Functional & accurate, just not ‘pretty’ ![]()

the 6061 cuts really nice on these machines with O-Flute tools. I even bought some O-flute ball mills.

Yup, I have a good range of them but have not used 0 flute ball mills. It is good old Rennie tools for my carbide ballnose endmills that are specifically for cutting aluminium. See here for sizes 1mm ~ 20mm:

For sizes from 0.2mm ~ 0.9mm for cutting aluminium, Rennie has this range of ballnose endmills: All of these smaller sizes are priced at a very reasonable £5.29 ($6.73) per piece including taxes.

All are relatively good value and very good jobbers quality so some cutters I have had almost 9 months use from.

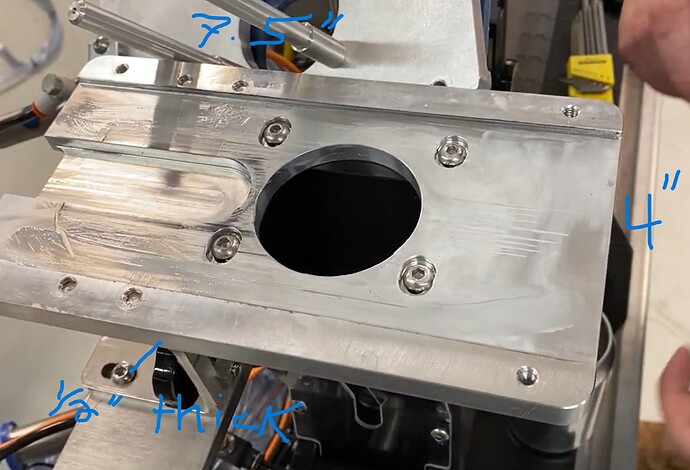

Yeah, I have the HDM but haven’t taken it out of the box/crate yet. I DID just buy a Haas super mini mill…lol But, I think I’m going to keep the HDM because I have a mounting plate which could be up to 22" x 16" and I should be able to do that with the HDM now that I’ve seen others’ work that it can do. Also, I may need larger sheets made from Delrin such as rails and decking. All my other parts will be milled on the Haas.

I’m going to keep the HDM. I have a feeling I’ll be glad I did.

Well, I didn’t want to take the chance. I have some parts that will need press fit bearings and also very nice surface finishes. i’ve also always wanted a mill.

You could look at the langmuir MR-1.

But, I do think the HDM should do a good job. I can use it for that larger mounting plate (1/2" aluminum). Also, for the longer delrin pieces that the mini mill just does not have the workspace for. I think, however, that the Langmuir MR-1 is a good machine from what I’ve seen and heard. I’m torn also on the HDM now, but will likely keep it to make those larger parts as they are not very thick or hard metals. Still up in the air but leaning towards keeping it.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.