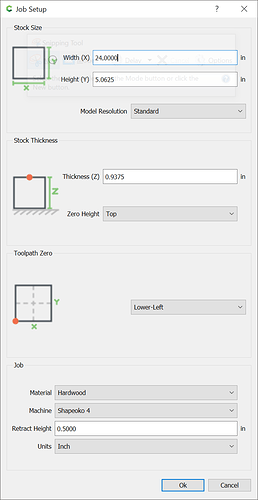

- You have defined the stock thickness to be almost 1" thick:

-

See above — If your stock is actually 1" thick, then yes, add a Base to get the thickness to match

-

Base amount adds that thickness at the bottom — the various merge types interact w/ the preceding components, see: