That said, the best approach here is to rough out the design using a suitable 1/4" or 8mm tool, then only use the larger bowl bit for finishing passes and final shaping, removing only as much material as is necessary to achieve a good result reliably.

An example of this sort of thing:

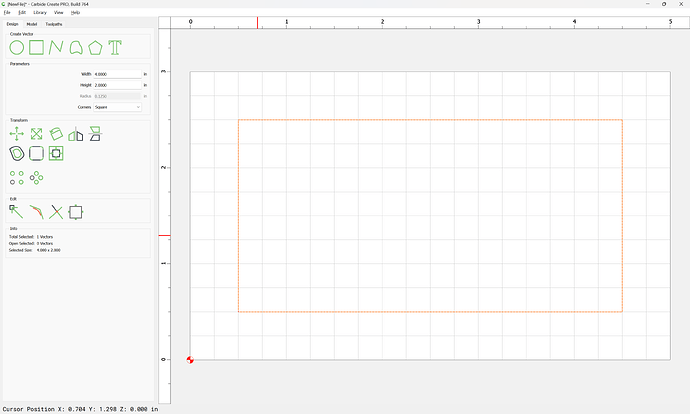

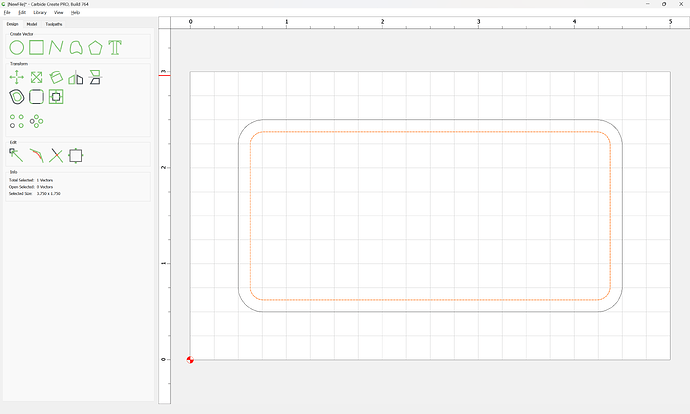

Given a small pocket which we wish to have a rounded bottom:

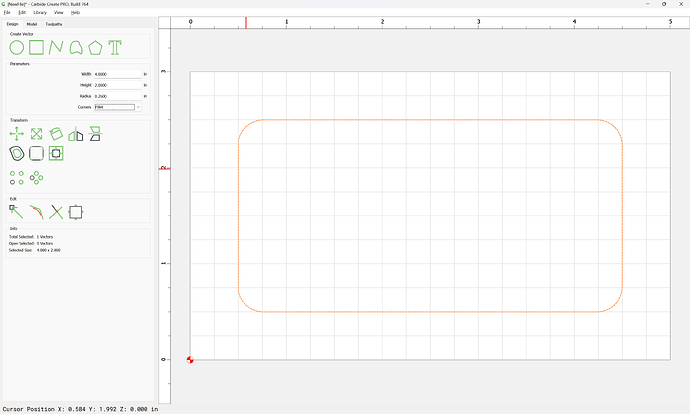

and which we are using a 1/4" ball-nosed tool to round, we start by rounding the corners:

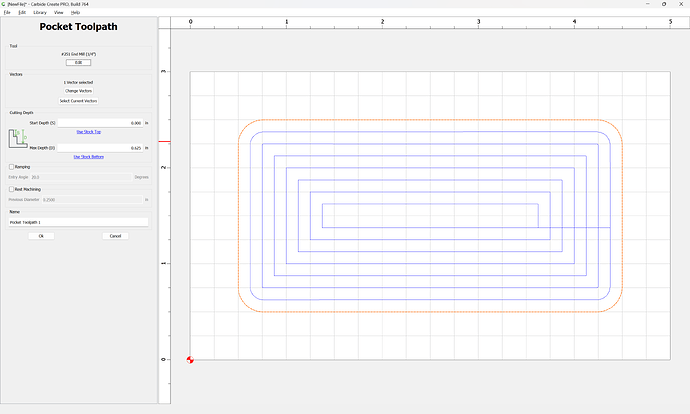

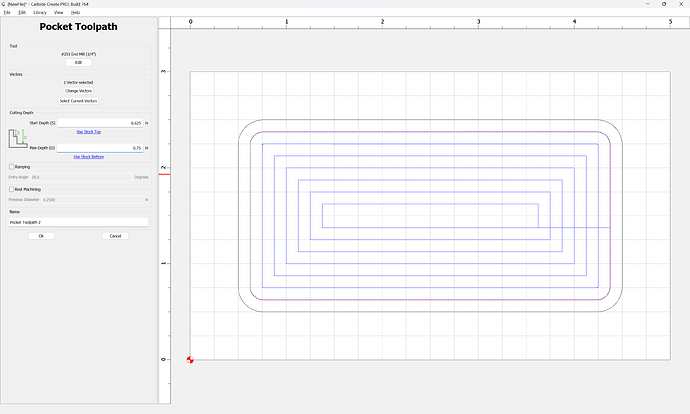

and we plot out a toolpath to the desired depth less than the radius of the tool or thereabouts:

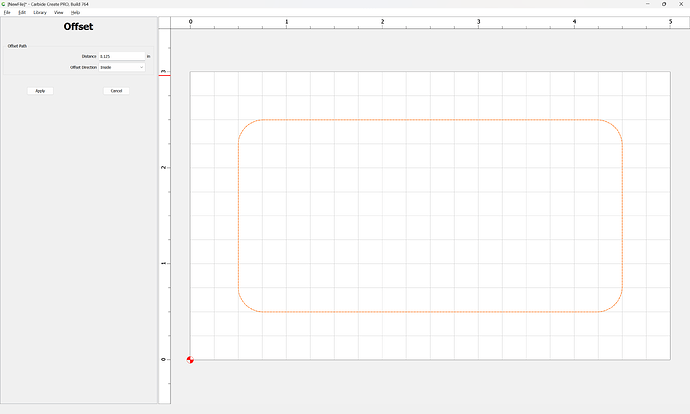

and we inset by the radius of that tool and add a second pocket which cuts the smooth bottom with this tool:

Apply

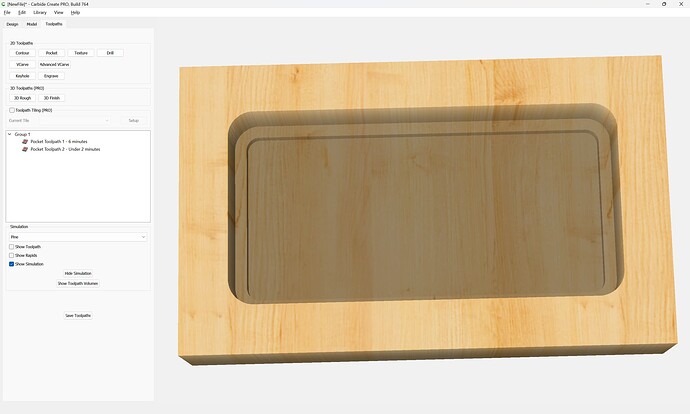

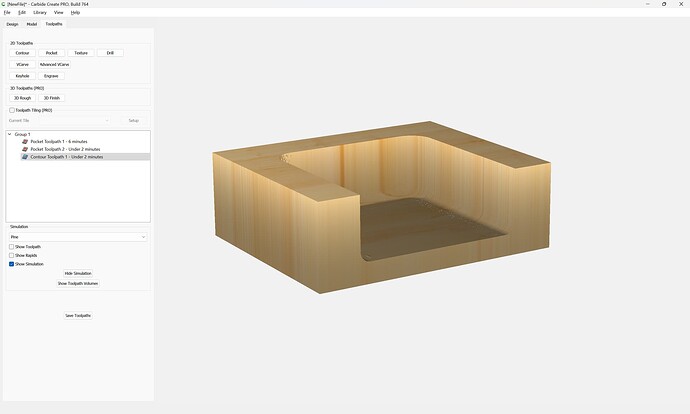

which previews as:

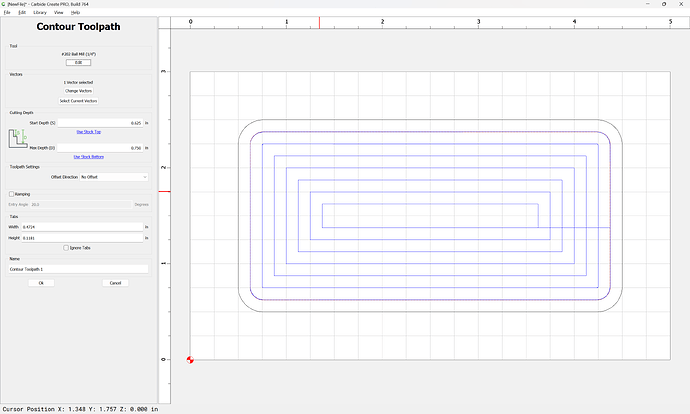

We then assign a No offset Contour toolpath to the inset geometry to the final depth starting at the depth of the shallower pocket:

so as to get the desired rounding:

which can be more clearly seen by reducing the stock: