How does the spindle runout compare to router runout?

Another question - will the speed/feedrates change with the spindle? My assumption is yes since it has more power and ability. Will there be an update to CCv6 (the beta) to reflect that? Or should we plan to utilize GWizard? I noticed on the CCv6 beta that there are options for the HDM - would we use that?

Significantly less than a compact router.

Possibly, it depends on the material you are cutting but you will likely be able to increase feeds and speeds. HDM settings don’t have any bearing on the rest of the Shapeoko range.

Are there any plans to add a spindle speed override function for carbide VFD systems so users are not stuck jumping back and forth adjusting the CAM when testing? Is there a way to wire up 2 potentiometers one for feed the other rpm? It would make the system way more fluid to use.

Maybe, but we’re not sure if that’ll lead to more trouble than benefits right now.

Oh interesting, I was thinking CM would have a +/- speed % similar to feed rate.

Assuming I get the speed wrong in Fusion/CC (which I’m quite adept at ![]() ), can I still turn the dial on the VFD still to change the speed?

), can I still turn the dial on the VFD still to change the speed?

The ShopVac is the greatest contributor of “noise” to my setup, so when the bitsetter started turning on and off the shopVac, it was a game changer. Wondering if there are any creative solutions out there?

Get an iVac system going with a tool sensor ( https://www.ivacswitch.com/ivac-pro-auto-sensor/ ). It clamps over the cable and detects current to turn on the dust collector.

Clamp it to the high voltage power cable going to your VFD.

On my Haunyang VFD there are programable digital outputs. I have one that is on with power to control the chiller and another that is on with the spindle running to control my vacuum. The outputs are switching 5V to IOT power strips and works very well. The only thing I miss is the delayed off of the vacuum I had when running the router. With the Carbide router having locked parameters you may not have this option.

so with this spindle being air-cooled, does this mean Winston is getting a new sock?

Serious question though,

Are there any concerns with dust or anything, or was the sock on the router primarily for the brushes?

I keep asking @Luke and @wmoy if CM will get a speed override like the feed override already in it. Without being able to reach over to the dial to adjust, I will actually have to be better about documenting feeds/speeds and not winging it every time…which I should be doing anyway. Another suggestion I have mentioned to them a lot is a pendant. The Rii keyboard is nice for jogging, but something I can operate with dedicated buttons/dials would be AWESOME. Or if we could have something like a feed/hold, and override hot keys in the UI without having to hover over a screen button.

For the pendant, the best options I’ve found are:

(wants a few more keys)

and the gamepad from:

(has two dead keys, and two buttons are kind of confusing — really wish the faster/slower feed rate buttons from joysticks would also show up as keyboard shortcuts)

Has it been mentioned how long the cable is between the VFD and the spindle?

About 14 and a half feet. Needs a bit more than the Compact router’s cord length to permit more flexibility in VFD placement, especially on an XXL size machine.

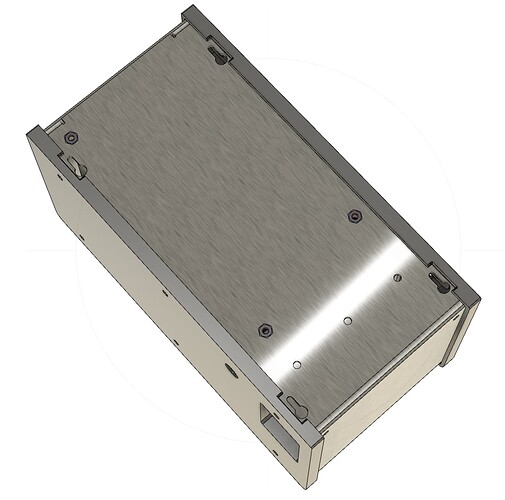

Thanks for the answer, quick follow up rough dimensions of the enclosure are are there mounting points built in or not?

Looking at the Carbide Motion download page there are notes for update 551 so don’t forget up update your version of Carbide Motion if you get the spindle kit.

- (NEW) Change spindle config for Shapeoko to add VFD Spindle option

Any reason an old version of Carbide Motion wouldn’t work with the spindle? It was already PWM’ing the output on the BitRunner port.

(I’m on v537 which doesn’t have the jogging/toolchange babysitting)

There’s a couple holes in the back to hang the VFD if desired. 113mm x 200mm spacing.

@greg5 The default “max RPM” grbl value is set very low (1000) so that basically any commanded RPM will saturate the pwm signal and activate the BitRunner. v551’s VFD config changes the max RPM to 24k so the PWM value scales appropriately.

I guess I’m wondering about max RPM and the implications when working with wood.

24k, versus a Makita trim router at 30krpm.

More RPM makes a smaller chip… less rigidity demands? Right now I remove the bulk of my material with an adaptive clear at 27k RPM. I guess the spindle might let me run a deeper DOC, perhaps at a slower feed rate, but end up with higher MRR?

I don’t think there will be too much difference in wood between 24k and 27k. Of the materials I have cut, wood has the widest range of RPM/chipload that works well. But I think you’re right in your assumption that the increased power of the spindle would allow you to go with more DOC or stepover to have the same or better MMR. With the increased rigidity of the SOPro/SO4 I have found router power to be a limitation before the motion system. I have the C3D router bogging in a cut before I skip steps, and in many cases before chatter sets in. The router and motion system were about evenly matched on my upgraded SO3.