Hi guys, this one isn’t so much a question as some learnings I wanted to share so the next poor guy googling around looking to repair his C3D spindle has an answer.

So the carbide compact spindle/router that came with my Shapeoko 4 was perhaps never as tight at the nose as one would have hoped, and it was like this from new. I always assumed it was a less-than-wonderful bearing, but having owned a handful of cheap routers with a similar problem over the years I figured it’d be fine for a while before I really had to deal with it.

Well a while came (I’m a hobbyist so after a couple years, but not a lot of use) and the chattering when cutting became a real problem.

I reached out to Carbide 3D and spoke to a nice gentleman named Brandon who told me that Carbide 3D offers no support for the Carbide 3D spindles of any type, repair or parts, and that the only pathway was replacement. And because I was outside of the warranty period, I’d have to buy a new spindle myself. Fair enough, they aren’t the most expensive thing in the world, so after a bit of research I ordered a new one.

Now that being said, the one thing I really waffled on was buying another C3D spindle, or a Makita. Reading online, people insist the Makita and C3D are “identical,” and the Makita has parts support. But “identical” and “identical-ish” are two different things when it comes time to swapping parts. I own a number of Makita routers and absolutely love them, so almost went for the Makita, but in the end the idea of having two C3D spindles that I knew were truly identical was just too tempting so I bought another C3D with the intent to repair the first one. On the subject of how "identical they are though, I found the following reddit thread:

https://www.reddit.com/r/hobbycnc/comments/wh7ite/quick_question_about_makita_vs_carbide_router/

Where a user named WillAdams who said he works for C3D wrote the following:

The differences are:

- Carbide Compact Router has a longer cord

- Carbide Compact Router is bundled w/ a pair of 1/8" and 1/4" precision collets

- Carbide Compact Router has a dial w/ detents which won’t vibrate off position

- there is an ER-11 variant

- and it’s black/gray and has a warranty from Carbide 3D

The Makita is:

- teal

- different control layout

- dial which for some folks vibrates off position

- Makita warranty, w/ a local dealer network/service center and easy availability at home centers and woodworking dealers

Things which are the same/interchangeable:

- brushes

- collets

- nut

- bearings

- motor housing

- motor

The new spindle showed up and was actually tight, no slop in the tool head. Thats a big improvement over the first one! Installed it and it is running well, so yay. Pulled the old one apart and immediately learned something:

The bearing, while not the most wonderful, was still perfectly tight. The problem was the bearing shim which sits between the aluminum housing and the bearing. It was tight on the bearing, but loose in the housing. So the spindle was manufactured incorrectly from the factory, that shim was able to rotate, and over time it worked itself to a point of looseness where the spindle became unusable. Ha!

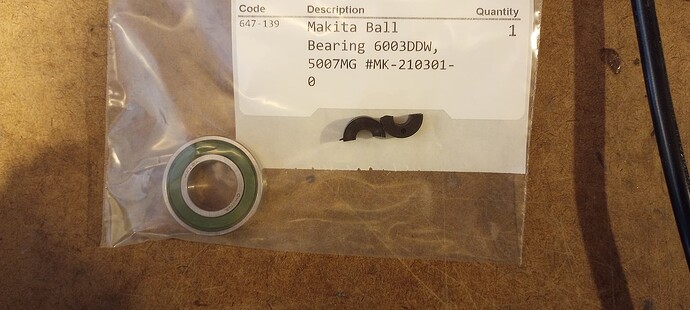

While I was in there I also did a little measuring, and I believe that, just like the Makita, it is a 6003 series bearing. Unfortunately, if you go looking for 6003 bearings, none of them are specd. for 30Krpm, and many are surprisingly expensive, so it turned out the cheapest/best solution was to just buy the Makita factory part. I haven’t tested this bearing in one of the C3D spindles, but maybe this’ll help the next guy.

To fix the loose bearing shim, I mixed up some high temperature epoxy with silicon carbide and milled glass, and bedded the shim in the housing. I then reinstalled the motor armature assembly. While doing so, I noticed there was an odd thick black ring on the back. I assumed it was some sort of retainer, didn’t think much of it. Placed a piece of wood over top to keep from damaging the armature, and gently tapped it into place. This was a mistake. When I moved the wood away I noticed the black ring had cracked, and it became immediately obvious what its function was: it was a magnet, utilized by the hall effect sensor in the speed controller to regulate the spindle RPM. This is why this little brushed motor can produce high torque at lower RPMs. So off I went to find a replacement magnet and THAT is when I discovered that these C3D spindles are NOT rebranded Makitas, they are in fact Makita clones. I found that out because the Makita part has flats ground onto the shaft for the magnet, presumably so the magnets have a lower failure rate (cracking) when being press fit as they needn’t be as tight to keep from spinning on the shaft.

The repaired spindle runs great… but only flat out, which is not very useful. Haven’t been able to find a replacement magnet, and machining magnets is awful. I’m also a little leery of putting another 15$, which is more than 10% the cost of a whole new Makita spindle, into a magnet I may or may not be able to machine to fit anyway.

And thats where I’m at now. I hope someone else out there either looking for information on which spindle to buy, or how to repair their C3D spindle, finds this helpful. Also, if anyone has a burned out C3D spindle they’d pull the magnet off the back of and mail it to me, I’d be really grateful. ![]()