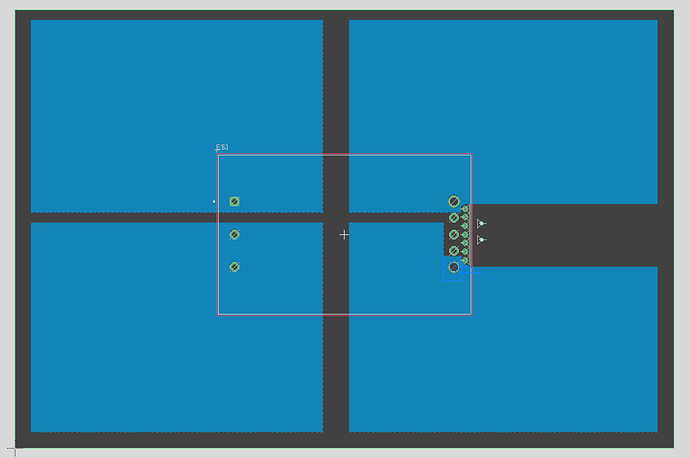

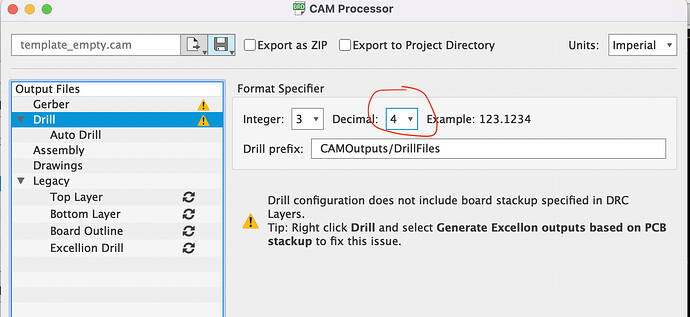

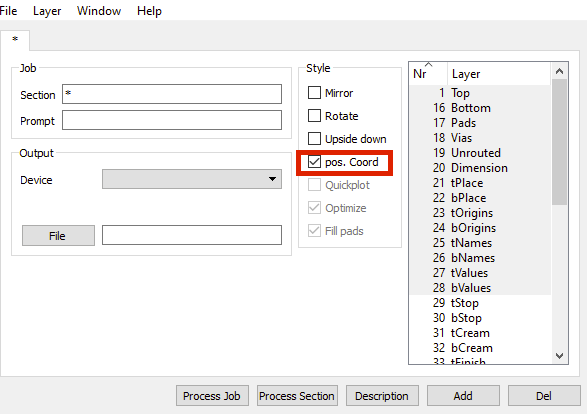

Trying something new and I really do not understand what is going on. I have Fusion 360 and Eagle, both of the cam processors give me the same results.

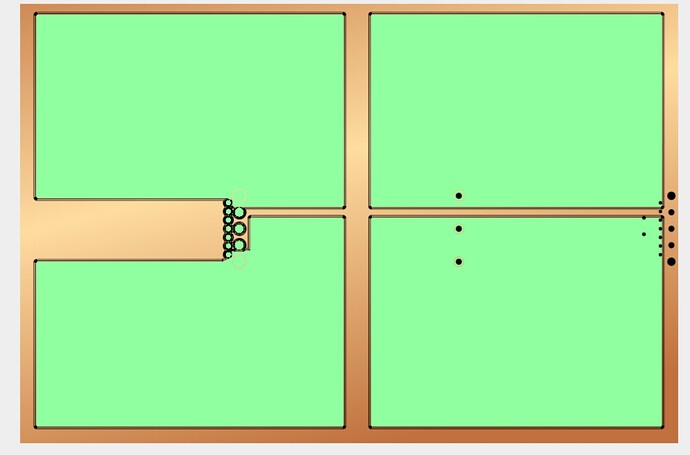

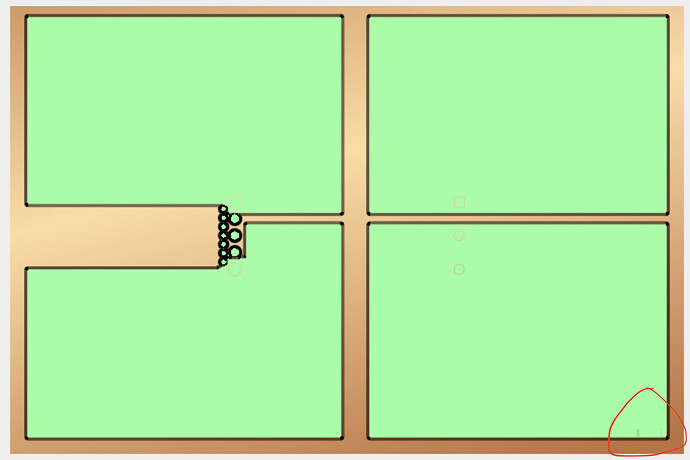

I can load the copper files just fine. When I load the drill holes, well, it just isn’t placing them correctly. See the attached images.

Blue is Fusion 360, Copper is well, Carbide Copper. I get that things get flipped depending on if I use top or bottom, but it isn’t just flipped. Part of the holes line up, but part are flipped and kind of inverted? Hopefully you can see what I mean by the pics.

Any ideas? I have been playing with this for hours now and same results each time.

Update I did just find the CAM file that carbide made for Copper, but using that I get no holes instead of holes being somewhat inverted and flipped. ![]()

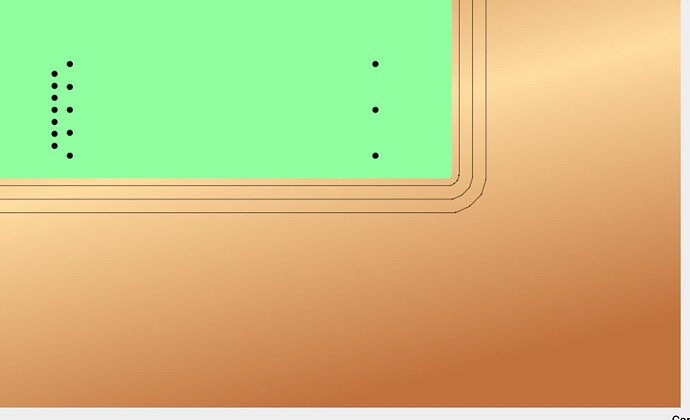

Update 2 Going back to stock Fusion CAM Export, when I export as imperial, I thought it wasn’t doing much, but it was making super tiny holes. (last 2 pics) They are however the correct pattern, just, well, the size of a pin. So, scaling then?