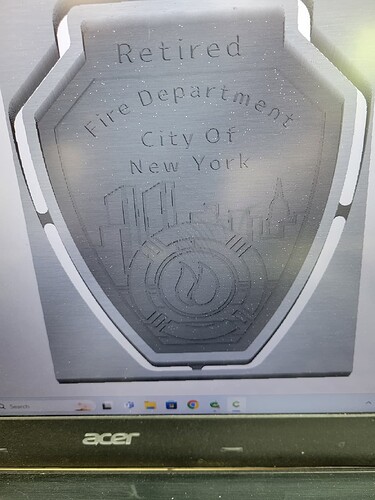

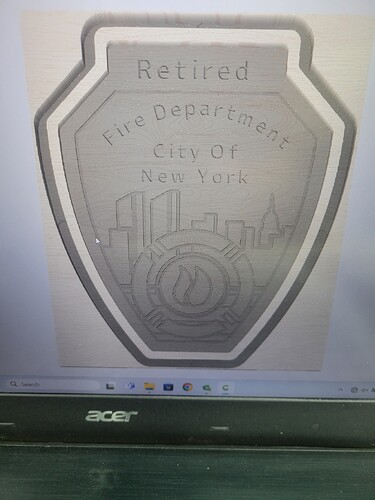

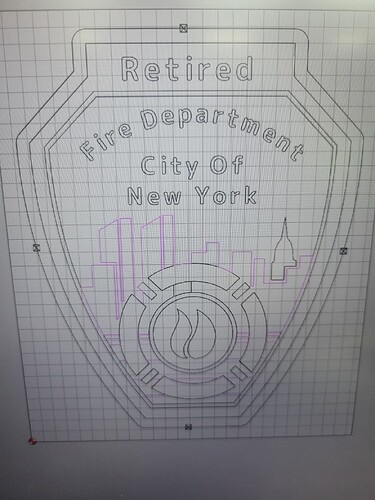

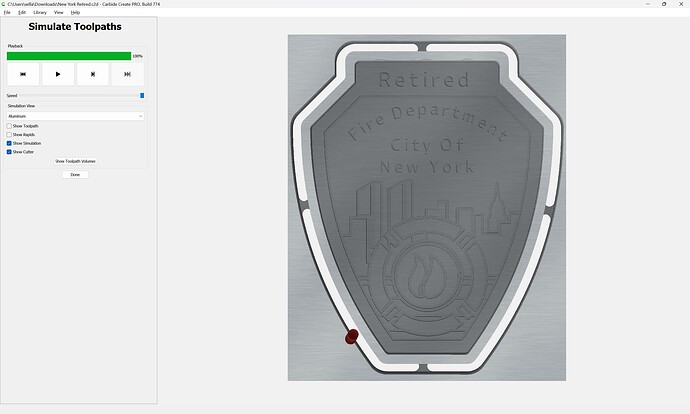

My design looks correct in CC (See pics 1, 2, & 3). But the machine is cutting wrong (see pics 4 & 5). I rebooted everything after picture 4 cut. But it is still wrong in cut 5. Any ideas what may be wrong?

It looks as if what is happening is either the machine is losing steps while cutting the earlier operations, or the machine is being shifted when the tool change is made.

Which machine do you have? Is it mechanically sound?

How are you managing tool changes?

I have the 5 Pro. I use the bit setter for every tool change. The machine is only a couple of months old so it should be fine.

Material measurement issue or the way you are

setting XY maybe?

Post your .c2d file?

Are you cutting a lot of slots?

Does your machine need to be lubricated?

No slot’s besides the cutout of the whole thing.

New York Retired.c2d (588 KB)

The machine is only about two or three months old so I don’t think it needs lubricated. All my other projects have been turning out fine prior to this problem. And I use the BitZero to determine the XY&Z.

That design is being cut at the bottom of an 0.5" deep pocket:

(note also that it is a bit close to the edge of the pocket and some of the wall is being cut away by the V endmill)

My recommendation would be to start with a simpler version of the file, or to do a couple of tutorials in scrap:

After doing “Hello World”

https://my.carbide3d.com/gswso/09

do:

Hello Contour:

https://my.carbide3d.com/gswso/10

Hello Pocket:

https://my.carbide3d.com/gswso/11

Hello V-Carve:

https://my.carbide3d.com/gswso/12

Lean from any difficulties you have, and build on your successes — once you’ve got each technique successfully cut you can build on them and with them.

The great thing about CNC is that given a properly prepared file, a machine setup which matches the file, and nothing going wrong in the cutting, a part will be made correctly.

The awful thing about CNC is that a part will only be made correctly if the file is prepared properly, the machine set up to match the file, and nothing goes wrong in the cutting.

It looks like, in both cases it is failing cutting the horizontal lines in the “City” toolpath. (red)

The next feature cut is the green line, which should be directly above the top horizontal line in that area.

Either the cutter is binding, or something is preventing the machine from moving to the right.

Your toolpaths don’t look unreasonable, S&F and DOC look OK. However, you are “slotting” with a 1/16" tool 0.100" deep. Your “Words” toolpath should be cutting about 0.030" - 0.035" deep.

Try running the path and cutting air. Set your Z zero about 1" above the part & run just the “city” path.

Try to set the job in the same place in X & Y. If there is something going on mechanically in that area, you should see it fail. If not, then it is likely binding in the wood, or getting hung up on something.

This topic was automatically closed after 30 days. New replies are no longer allowed.