Yeah if the new software allows you can do that. All personal preference, I still personally would start back at the tool change line if I broke a tool just as I do with all the Haas machines I work with. It might be cutting air for a few but I can still verify it’s all good and doing what it’s supposed to

Really glad to see some progress here. When comparing Carbide3D to Onefinity and their Masso Touch CNC Controller interface, Cabide3D has a lot of catching up to do. I think investing in this area is super important as this is one of your competitors main value propositions over you guys.

Just a suggestion. If CM could continuously output the last so many lines to a text file ( rolling buffer ) , then you could easily determine the last line performed before an unplanned stop, crash, reboot or even a power outage.

Unfortunately, there is no way to determine what the last line executed was. CM can keep track of the last line that was successfully transmitted, but the controller has an internal planning buffer, and there’s no way to know how far into that it was when the machine stopped.

That would be close enough for me!

You’re 4 hours into a 5 hour finish path & the tool breaks or wears & starts to bind. You’re not going to want to restart at the toolchange. ![]()

Previously you’d have to change your cut boundary or start depth & regenerate the tool path, output it, and execute it. Now you just estimate the stop point & start a bit before it.

Todd, I completely understand your point, but I personally won’t ever have to deal with that because I don’t run jobs that run a four hour tool path. I don’t plan on ever running anything 3D at home.

At work running aluminum I have restarted many times on broken tools that are well into a 2-3 hour tool path right from the beginning as that is what both the boss and I choose to do. Once again, personal preference

I had a 4 hour program loose connection and freeze. I followed the restart and picked a point several lines before where it had stopped so there would be no material to remove.

It went to the bit setter the prompted to turn on the router. Everything seemed fine, but some how the z must have been off a few thousands, because the bit started removing material and before I could stop it the .0625 ball end mill snapped off. Is there anything else I should verify before sacrificing another bit ?

Do you have a photo of the section where the recut began and the cutter snapped?

The streaming real time status messages from grbl will give you the last tool position. The last sent gcode command, i.e. the last buffered ahead line could be used with the rtsm to get pretty darn close to the last actual cutting location. When doing this by hand I search backwards to the prior Z move, maybe more than one if it’s a broken tool, to decide what gcode line to start on

Theres not a lot to see, but the pass was from right to left above the center of the chest. About 3/4 of an inch above is where it froze.

As someone new to the hobby what are your thoughts on the surface finish? I don’t really know what I can expect. This is a .003 step over as well as a .003 depth of cut. Feedrate around 70 ipm at 20,000 rpms.

The tool path is one direction as well.

Thanks for your time.

I just downloaded the latest beta to my S5Pro computer.

I love the addition of the tool descriptions being in the preview and tool change pop-ups.

Jogging is in fact way smoother.

I have not tried the pause feature.

Hi Rob, These will be great additions for sure. I do this with a work around now so getting to restart without additional efforts will be great.

I do have one feature request as well. How about being able to install and open CM without being attached to the physical machine. When I need to work through an issue between CC and CM it would be nice to do it in comfort of my home office and not have to be in the shop just because the hardware is there. I need an “offline” mode button.

1/2 way through an hour-long toolpath, I decided that a later toolpath would not be needed. So I:

- Stopped the current program

- Disabled the toolpath and re-saved the file in CC

- Reloaded the file in CM

- Restarted a few dozen lines before where it stopped.

Worked perfectly.

This relies a lot on how deterministic toolpath generation is in CC, but it worked for me!

We essentially use the machine as a dongle for Carbide Create as noted in:

https://carbide3d.com/blog/carbide-create-v7/

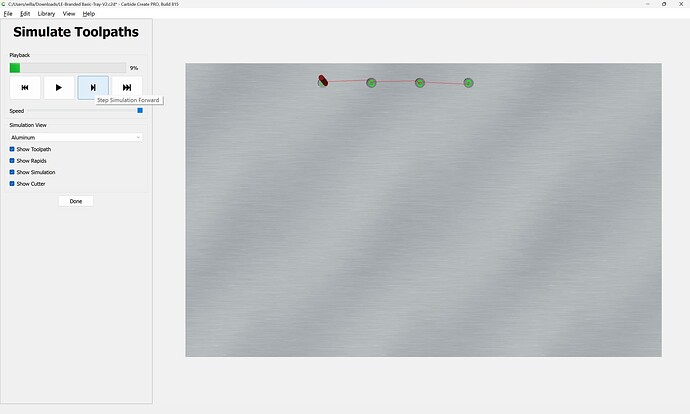

Are the Simulate Toolpath controls for G-code Preview not sufficient?

Using the “Step Forward” button, one can do just that:

It is not sufficient for those of us that use other design programs.

If you want something like to the wireframe preview afforded by Carbide Motion, then there are a lot of options.

is probably the most popular.

I’ve been using the Notepad++ plug-in from NCnetic:

and have a little side project which does surface modeling based on 3D models of cutting tools and modeling G-code and which can also do interpretation (needs a lot of optimization though).

It does not depend on CC. It works for just about any common CAD/CAM package that does a toolpath “the typical way.” You can absolutely write G-code that we didn’t anticipate in our testing, but that won’t be G-code that came from CC, Vectric, Fusion, etc. G-code from those programs should work fine.

What would offline mode do?

As someone who has broken a lot of endmills learning the ins and outs of CNC Machining Program Restart sounds like an amazing feature. I cannot wait for this to move out of Beta so my boss will let me use it in production.

On the topic of broken endmills I would like to humbly request that you please add the ability to move the tool change location when using BitSetter. The currently location on an S5 Pro is directly over a gap in the hybrid table. I have been doing a lot of fine detailed machining with 0.5mm endmills lately. I have broken 3 of them during tool changes as they sometimes fall out of the collet on the Carbide Router onto the aluminum extrusions while I am using two wretches to open the collet. If I could move the location even an inch to the left or right they would fall onto the MDF and hopefully be spared. I understand that this is not likely to make it into the latest Beta, but if you could please add it to your dev queue I (an I think a number of others) would be most grateful.

I’ve just been putting a folding silicone parts catch tray under the tool change position when making tool changes (and I try to reach under/around tooling so I’ll catch it if it slips).