So I just downloaded the V5 update.

I have my settings to lift up .5" in file. When I went into new Motion it didn’t lift and slide across the board. What am I doing wrong?

Post the .c2d file, generated G-Code, and step-by-step notes on how you are securing your stock and setting zero relative to it.

Holdaway.c2d (196.2 KB)

Holdaway2.nc (111.4 KB)

I’m cut PVC- 1/8 spiral O flute 1 flute

Open it in Carbide Motion V5

Zero in far left front corner after homing.

Secured with brad nails.

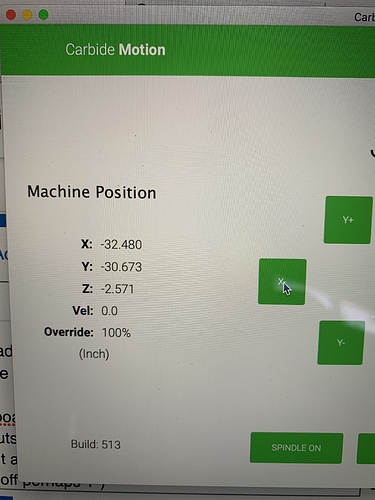

After it slid across and was unsuccessful I attempted again with same result. Now, I am also encountering now that it won’t go as far to the left on x-axis as it normally would.

I upgraded as Motion 4 I kept getting error codes coming up during cuts and couldn’t pause or stop the job without hard shutting it down. It would come up with Error 8 and 3.

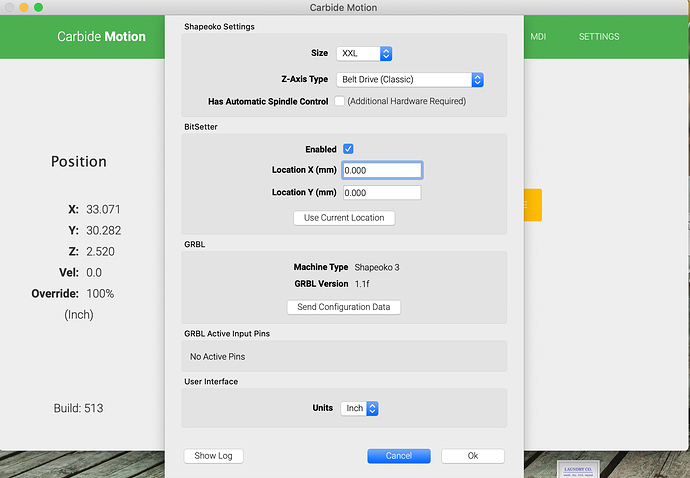

Did you configure the machine for your size and accessories?

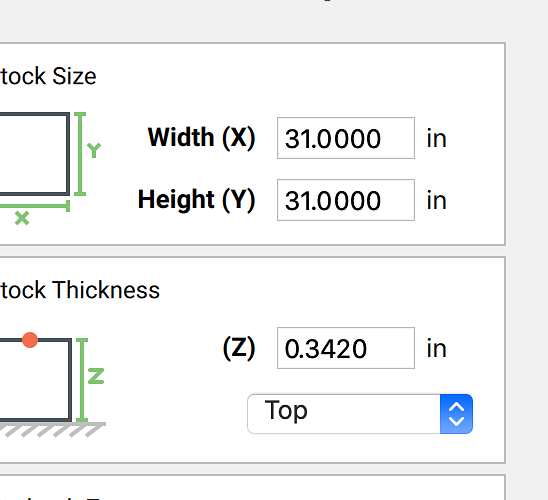

Are you zeroing on the top of the stock or at the surface of the wasteboard?

If there reference to this? I can only find V4 on configuring machine. I have gone in and Homed it, followed by clicking settings, open the log and then set XXL and finally clicked send configuration. Let me know if I am missing a step.

It’s substantively the same as v4 — please let us know which machine/accessories you have and post a screen grab of your settings pane.

I appreciate you helping me. I have Shapeoko XXL and no additional accessories. I’m still new to this world.

you said you have no additional accessories but you have the BitSetter checked as enabled. uncheck it unless you have one

I followed the step below in unclicking the bitsetter option (I know I unclicked the last time forgot in screenshot). I attempted again this am and this did not help. My GCode has it that it lifts .5" on z axis when it moves to cuts. It does not do this step.

I am still new to the land of CNC. I have only had to machine configure once so far for V4. I’m not sure what I am missing here and why this isn’t working. Someone has has stated they too are having the same issue on a Facebook group.

Still no dice…

It won’t move up .5" on z axis (retract setting I have)

I uninstalled and reinstalled Mac Version of V5.

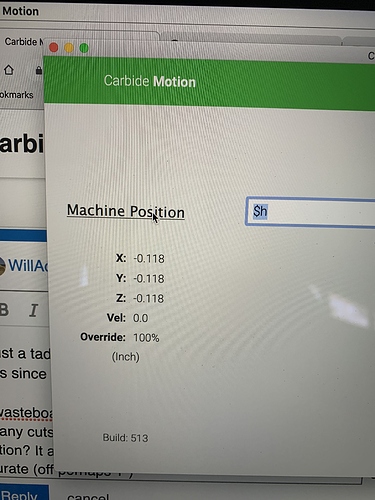

Opened up and connected- Click connect cutter

Then went to settings, unclicked bit setter, selected xxl, opened log, clicked send configuration and once complete clicked OK. Then went and clicked initialize. What am I doing wrong?

2nd thing I am confused with…I am no CNC expert and don’t know proper terminology.

My wasteboard was set to a specific place due to position of many cuts I have done. Now the router can’t reach that position? It appears like when home is done that its not accurate (off perhaps 1") If I clicked SW on the jog it would take me there before.

I opened your gcode file and then exported one directly out of Carbide Create with the Shapeoko Post Processor from your design. I’m still learning gcode myself, but I don’t see the initial Z height on your gcode until the spindle motion starts.

Here’s the gcode from CC

G90

G21

(Move to safe Z to avoid workholding)

G53G0Z-5.000

(Toolpath 12)

M05

(TOOL/MILL,3.17, 0.00, 0.00, 0.00)

M6T19

M03S18000

(PREPOSITION FOR RAPID PLUNGE)

G0X567.45Y627.82

Z12.70

G1Z-8.69F635.0

I’m not seeing that in your gcode. Am I missing it?

Here’s yours:

G90

G21

(Toolpath 12)

M05

M0 ;T19

M03S18000

G0X567.45Y627.82Z12.70

G1Z-8.69F635.0

Guys, am I reading that right?

I’m still learning the terms it’s the retract height I am referring to! Sorry for my poor details.

So, when the program runs it doesn’t retract up .5 from the top of the material. It just starts sliding across my PVC as soon as it starts. This is the part I do not get! It hasn’t happened to me before. Maybe my eyes aren’t catching something small.

The G53 move is specific to the Carbide 3D post-processors — it shouldn’t cause a problem — if it does, please let us know at support@carbide3d.com — send us a .c2d file, generated G-Code, and step-by-step notes on how you are securing your stock and setting zero relative to it and note the step-by-step specifics which lead up to the issue.

Double check your post processing format in Carbide Create?

Edit > Select Post Processor > Carbide 3D Shapeoko

This topic was automatically closed after 30 days. New replies are no longer allowed.