Looked on Amazon and saw this which looked promising (although a bit pricey). Then I read the “Features and Description” section and have to wonder what exactly one would get.

Tony,

Sorry for the delay in replying. Unfortunately, I haven’t been back to doing anything on my SO3 XXL in a long time. Work, family and honestly I think a bit of depression pretty much killed my interest int he machine for the last year or so. I’m still doing ~30% OT, but I finally think I am coming out of my funk, because I’ve been thinking about clearing off the bed and doing some modifications to the spindle setup to reduce chatter when I cut aluminum.

I pretty much have the spindle as low as it can be mounted on my HDZ, and my bed is far enough away from the gantry that I have to have the HDZ as low as it will travel to reach the bed, so that moment arm is like 6" from the bottom V-wheel to the tip of the bit. That is what is causing my chatter when I cut aluminum. So, then plan is to move the spindle up in the mount, and build some flat and parallel surfaces spacers to get thin stock up higher so the spindle doesn’t have to travel so far down.

Anyway, that was a long way around to your answer, which is - other than my previous post on the subject, I don’t have anything to add at this time. But if I do get back into cutting marble, I’ll let you guys know what I learned.

@MadHatter thank you for your response… but more importantly hope you are coming out of the funk, hate to hear anyone dealing with depression and life kicking them in the rear! Just know you have a lot of us fellow woodworkers and hobbiest here for you my friend! Cant wait to see you back at the machine and what you create!

When cutting stone, diamond bits are recommended, but for softer stones (marble, limestone, soapstone) carbide bits can be used. Dry cutting can be done, but heat build up will shorten the life of the bits and can result it the stone spalling out (chipped edges/faces) so water coolant is recommended as well.

As for dust, with a true marble it is only a nuisance not a health issue. However anything containing silica (quartz, quartzites, granites, sandstone, etc) the dust is a health issue. While cutting wet helps keep the dust down, I would still recommend a N95 mask when working with any stone that contains silica. Unfortunately stone classification isn’t as straightforward as wood or metal and a lot of stone is misclassified either by the quarry or the US distributors. Also you can have a piece of stone that is primarily one type (ie marble) with inclusions of other minerals (say quartz) mixed in.

@TonyMurray, thank you for the kind words.

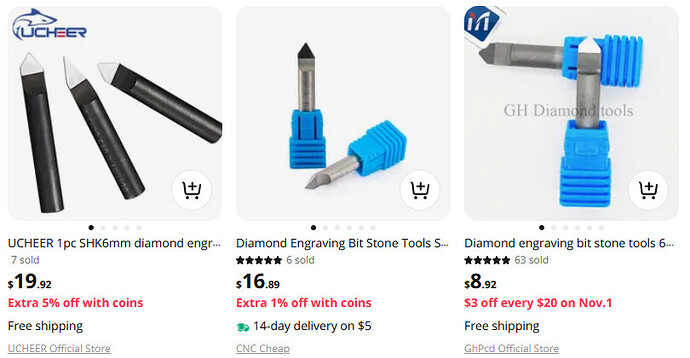

I went back and looked at my older post where I linked to the bits I used for cutting marble, and found it was a dead link. I guess that makes sense. Here is a better way to find the bits I was using:

- Go to https://www.aliexpress.com

- Search for “pcd engraving bit”

You should get hits like this:

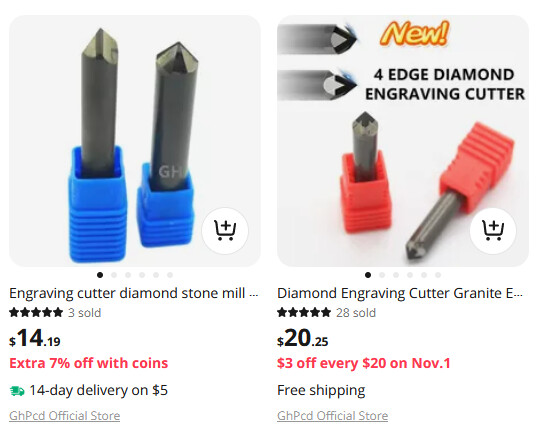

There are a couple of different styles of bits. I have only used the ones that look like those. There is another style of bit that looks like a 4 sided pyramid, and the diamond bits are the corners of the pyramid, like this:

But I have not used that style, so I can’t comment on how well they work, or whether they need lubrication when cutting.

I know I can cut marble just fine with the top ones just fine dry.

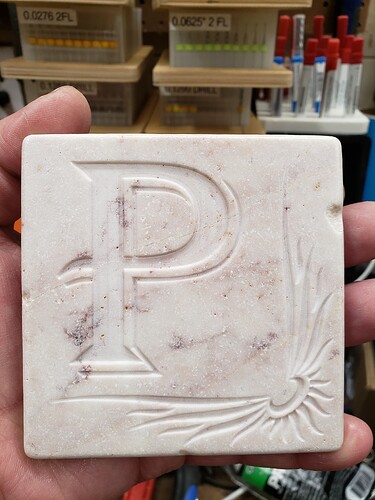

Trying out different patterns to see what looks nice. Sometimes what looks good on the screen takes on a different look/feel once it is engraved on whatever medium you are planning on using, so when the test pieces are cheap (these were like $1/ea I think) I don’t mind sacrificing one or two to make sure the final product is what I had in mind.

Guys, don’t forget the option of trying solid surface (Corian). It machines well with carbide bits like hardwood and there are multitude of colors. The only thing is if you want anything thicker than 1/2" then you need to glue pieces to gain the desired thickness. After machining the pieces can be fine sanded (dry and wet) and polishes to a shine. If glues properly, you will never know the pieces are glued together.

Hi Dennis, Corian is great option. It machines very well, proper dust collection and respirator for secondary processing as the dust is very fine and not at all good for you.

A recent batch of 6 inch trivets.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.