Has anyone ever tried to CNC Marble? It is a softer stone but was thinking if trying it? For the record i have a stick 3xxl but have pushed it hard and always thunking if nee things. My idea would be to do more chess pieces out of marble if possible. Thoughts?

Folks have done it. Usually it wants coolant.

Note that it may contain quartz which will dull bits.

Thanks @WillAdams for the quick reply, definitely will look out for quartz I sold my chess set that I made and posted on here so thinking of makong another and thought well why not try marble or something else!

@MadHatter any tips on bits I seen on here where you cut marble!

I got some Dremel diamond coated bits for stone carving on Amazon.

I found it to be messy. I ended up using water to help with dust and keeping the noise down.

I know this isn’t the same as marble, but this would be a cheaper starting point.

I’d be afraid of the corrosion risk to everything metal/electronic with salt in the air even with good dust collection.

@LWSIV Great point… I am not sure I am going to do it just had the thought and thought I would share the idea for feedback from the community! Also trying to get the community and this forum back on purpose in my opinion (too much hatred and bashing being put on here!) @CullenS knows what I am talking about! Folks like me and I believe Cullen would agree come here for constructive feedback and lately been seeing too much destructive things!

No bashing or hate here. It is an interesting idea but I would want to figure out how to mitigate the risks before damaging my equipment. You can use old/disposable cutters but the rest of the machine needs protecting. Marble and soapstone can be cut wet, the salt would melt on you. Maybe that’s a feature - self sanding material ![]() .

.

My boys had to do a carving in Cub Scouts. The den leader gave them a couple of bars of Irish Spring and a plastic butter knife. It was a disaster.

Maybe I should try soap instead of soapstone on the machine and have them take it back to the den leader.

The idea of having any liquid near my machine gives me hives so I don’t currently plan on any of that really hard stuff at this point.

@LWSIV I agree nothing but respect for you and your ideas just tired of others not providing a meaningful input or solutions so all meaningful comments welcome, i never really though about the salt aspect so definitely appreciate that. @CullenS actual soap is a good idea to try. I dont know about liquid either but had the plan of a drainage solutions recycling coolant or a tray to carve in. Not sure just like some of yall got a wild idea and seeing where it takes me. Lol

I agree water is also concerning. I have seen some videos with very clever containers with fixturing inside for submerged stone machining. I am concerned enough with a spray bottle making a little puddle when diamond drag engraving on Marble or Basalt. It does force a prompt cleaning of the machine with a re-lube of the metal surfaces. I did switch to an HDPE spoil board so I don’t have to worry about MDF swelling.

You mentioned soapstone earlier. I just happened across this video from @45rpm John Clark

Looks interesting and he did not use lubrication.

Soapstone is a very different animal. It’s basically highly compressed talc. It cuts like butter (Very dusty butter, which is probably not great for your lungs so dust collection is good). No water needed. It would be cool for chess pieces I think.

I think I did a marble tile once as an experiment. It’s fine with a proper bit, but it would probably need coolant as Will noted. I am always terrified of anything that might get the MDF base wet.

@LWSIV I have been wanting to do an HDPE wasteboard so this might be a good excuse lol, as I wouldnt want to risk with MDF, @CullenS and @45rpm I think if I do try it i will go woth the soapstone 1 because it is cheaper and 2 seems a lot easier, hearing from you two is funny since the 3 of us are all in GA!

@45rpm any tips or tricks other than your video about soapstone I should be aware of? I assume no specialty bits needed with its softness?

It’s noted as being abrasive and dusty.

You may find this link of interest:

Thanks @WillAdams always looking out!

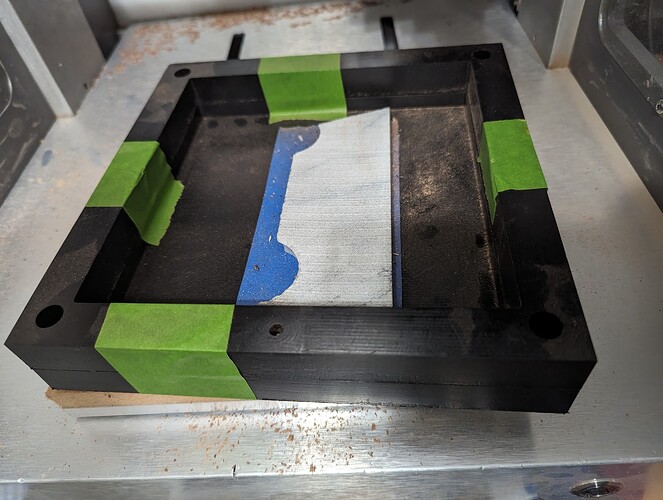

If I had to do it again (and probably will eventually). I have a thing that I need to seal the two layers together, but was going to use this:

It was a mess on the old nomad I had. I wasn’t entirely prepared to introduce water into the mix. When I ran the first project I ended up using a pipette to drip water infront of the tool, hoping to minimize the water.

No special bits, but as Will said it’s very dusty and not at all lung friendly. Mask ++

It’s always good to do some small tests to see how fine the detail can get before it starts to crumble or chip. If I remember right, I also sliced mine on the band saw with no issues.