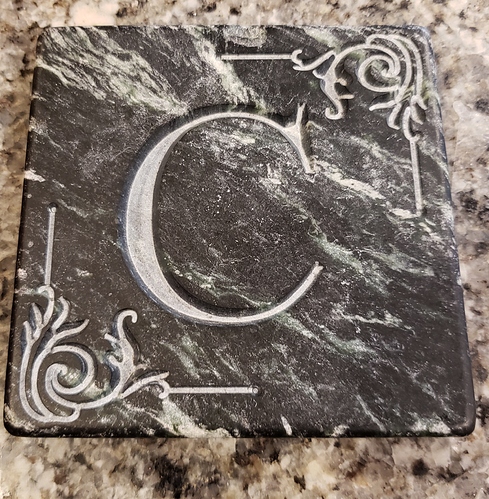

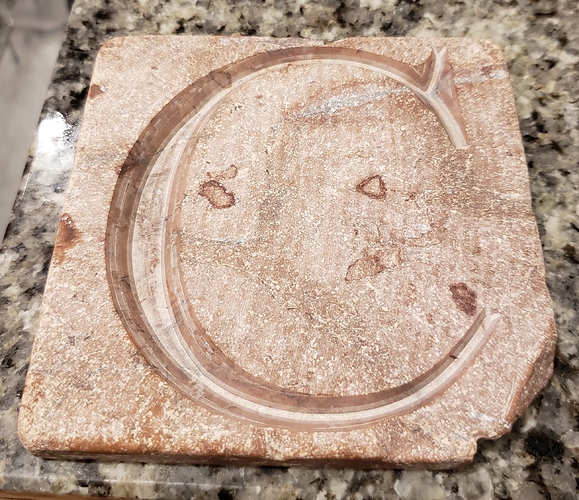

Here is what a Shapeoko can do with an inexpensive PCD V-bit. It’s a 12ish minute long video, so feel free to skip through it. I’ll add more info tomorrow.

Nice, I’ve done many tile engravings with a drag bit. Can you provide more info on the PCD V-bit you are using. How much depth do you carve? What F&S do you use?

Yes, I’d be interested in more details as well. Nice work!

I’m using these bits.. I ordered two each of the 60deg, 70deg and 90deg. I received four of the 70deg instead of the 60deg bits but I discovered it too late to exchange them. No worries though. I’m still enjoying them.

Feeds and speeds from the Vectric tool list for them:

Pass depth: 1.0mm

Final pass step over: 0.2mm

Clearance pass step over: 1.0mm

Spindle speed: 12k rpm

Feed rate: 20.0 ipm

Plunge rate: 15 ipm

Here’s a few more pics of tiles I’ve been practicing on.

Sorry but my Chinglish is not up to par, is this the price per bit, for a set of 5 or that there are 5 different types available?

They are ~$12-ish per bit. After whatever fees and taxes and whatnot, my 6 bits were just under $80.00 delivered.

I see that these bits have a 6 mm shank. Does anyone know if the Makita / Carbide Compact Router 1/4" collet will work with 6 mm shank tools? I know that the DeWalt collet will not close down enough to grab a 6 mm shank, and that a special 6 mm collet is needed.

Yes you should use appropriate size collets Elaire sells precision collets for Makita in mm sizes.

Yes, I realize using a 6 mm collet would be the proper way, but curious if a 1/4" collet would work in a pinch, since it’s only a 0.35 mm difference.

I think that @WillAdams had provided the amount of tolerance for collets and if memory serves me, it was not much meaning that it would be possible for a bit to come loose or overstretch a collet.

It’s my understanding that ER-style collets (and possibly similar collets such as the DeWalt DWP611) have a wider clamping range which might allow that to work, but it’s still not advisable — better to get the correct collet size.

For the Carbide Compact Router/Makita, there isn’t as much clamping range, so it’s not an option — get the right size collet. Makita makes 6mm available in some locales, or you can get the right collet from Elaire Corp.:

Also, these bits will take 2+ weeks to arrive to the US, so you have time to do some research and find an appropriate collet for your machine. Then. . .

Take a short vacation.

Order the new collet.

Take it for glamour shots when it arrives.

Place it on a shelf.

Forget about it.

Receive the PCD bits.

Wonder what the heck you ordered from China.

Open the package and then remember. . . Oh yeah, I get to cut stone now!

Actually, I know from personal experience that the standard 1/4" collet on the DeWalt DWP611 will NOT clamp onto a 6 mm collet. Based on what you said, the same is true for the Makita collet.

I guess if I want to try these “cheap” PCD V-bits, I’ll have to invest in the Elaire 6 mm Makita collet.

@MadHatter Yes, I know what you mean about those slow shipments from China. They only seem to show up after I’ve forgotten about them.

Didn’t you forget the step where you order a second new collet because of the steps where you placed the first one on a shelf and forgot about it? That could just be me.

Jim

Not a collet, but drill bits. I use these for drilling my cribbage board holes. I buy them 10 at a time, and I put them in these little plastic containers that hold ten bits and label them.

But I ran out of trays to hold the cases, so I put them away and forgot, so when I ran out of bits, I ordered another 20, since I know that I am going to use them eventually, and I’ll lower the “per bit” cost by spreading the shipping over more bits. Well, I found my other drill bits when I went to put away the extra ones after they arrived. So, now I have like 40+ of the 0.1250" carbide drill bits.

So, I completely understand.

Also, I designed and printed a couple of collet holders.

Thanks, Hatter. I appreciate the links. Drillman1 is becoming my goto guy. Those small shank organizers are now on my list. I don’t have that many tools in those sizes… yet.

Everytime I turn around, I see more proof that routing and 3D printing are linked.

From what you showed, it looks like you have a fine setup for getting your work out. I have a special interest in cribbage boards, too. I’m working on more designs, all the time.

Thanks, again,

Jim

Jim,

I’m glad I could help you out. 3D printing really is “the other hand” of CNC machining. With a CNC machine, you get it in your head that there is a “thing” you want and you design it and cut it and there it is. Sometimes that “thing” is just not machinable (or not worth the effort) - that is where 3D printing comes in.

3D printing allows you to really expand the custom “things” you can make to satisfy your need.

If you do happen to get a 3D printer, here is where my stuff is on Thingiverse if any of it might suit your needs / wants.

ER-11 Collet, Nut and Wrench Holders

PreciseBits Collet, Locknut and Wrench Holder for DeWalt Router