Hi folks! We typically do indoor items, but a friend asked us to do an outdoor sign for them. I created it using 3D modeling in CC. When I work through the toolpaths, they seem way longer to run than I would have expected. Any suggestions for how I could adjust?

Outdoor Sign Texture Exploration V6.c2d (2.2 MB)

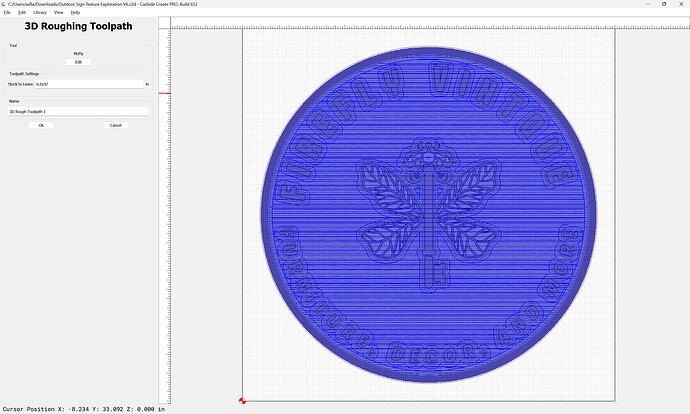

First off, the McFly is intended for facing, not material removal:

What material are you cutting?

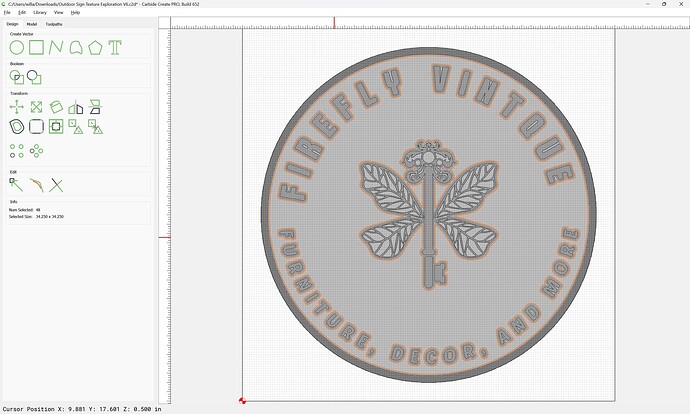

Second, if the field has been machined down to 0.5 inches:

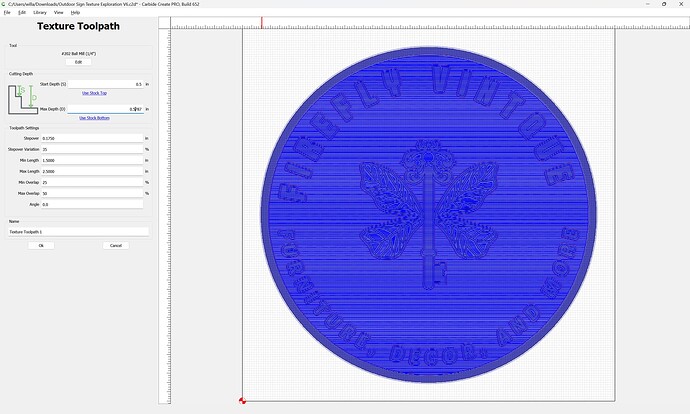

You will need to change the Texture toolpath to start at that depth:

Lastly, if you’re cutting the entire surface in 3D, why not make the texture part of the 3D model and cut it all at once?

We played around with the Mcly versus a 1/4" ball nose just to see the timing differences. I don’t think the McFly would do well with that kind of workload, either.

Thanks for the tip on the texture; I missed that part. I didn’t include it in the 3D model because I couldn’t find a picture to use that I liked. From the videos I watched, it looks like you have to upload a png or jpeg of the texture. Any recommendations or a similar look? I’d imagine that using it in 3D would make it quicker.

Draw in geometry which describes the regions you want cut away and remove them w/ appropriate settings from the 3D model.

I have the 65 mm spindle.

I just cut eastern pine (3.5 " deep) and I needed to remove a lot of material to get to the real model. I used the McFly @ .06 DOC @ 200 ipm for a 6 cu inch/min rate.

For Pine it was faster than I would send a 1/4 bit.

If it was hardwood, this story would change.

The big steps were cut with the McFly first to save time for a 3D Pocket.

That’s helpful! I am thinking of doing this with 4/4 cedar.

I’ve drawn out the spaces where I want the texture to be, but I don’t plan to draw it out line by line in the 3D model, if that’s what you mean.

I was watching this video to learn: https://www.youtube.com/watch?v=jDaaA5JLcKQ&ab_channel=CarbideAnswers

I don’t know how to draw out that geometry on my own without taking hours to complete or using a picture.

If I change the 3D Rough with the McFly to 0.3 DOC at 100 IPM, the cut time is reduced from 700ish minutes to 301 minutes.

You have a choice of design time vs. machine time — either is valid.

Note that for machine time, our feeds and speeds in Carbide Create are very conservative, and you should be able to push them quite a bit, see:

and

My inclination for speeding up roughing would be to get an 8mm endmill w/ an aggressive cutting flute geometry.

Your DOC of 0.3 is 5X more than my 0.06 DOC.

I don’t know if the cutters are that tall.

I tried 0.1 at 150 ipm and the spindle sound was different. When I ran into a knot, it definitely slowed down. I backed down.

Thank you! That’s helpful. Just trying to weigh out how to use the time wisely, I guess. Do you know if there is a texture library of sorts if I want to try to look for a photo option like in the video?

I’ve also never run a program that would take this much time before. Is this something that the machine can handle if I decide to do something like this file?

Typo, my bad lol. It was supposed to say 0.03 instead

We have folks who run the machines 8+ hours a day, day-in, day-out for production — your ability to monitor things is of more concern as a limit, so long as the machine stays clean (run dust collection) and nothing mechanically interferes (make sure that hoses/cords are routed safely and managed so that they will stay out of the way through a full range of motion.

I have an over night run going right now …

10 million+ line file.

The picture above is the rough cut of a laser scan of my wife’s Miata. Making a 50% version.

I am not sure if I will let it go by itself tonight.

I can pause and hope for no computer gremlins or let it rip.

@WillAdams @jtclose that’s good to know! Most of the stuff we run is only about 4-6 hours. I appreciate the feedback from both of you!

Note that we specifically enjoin folks not to allow machines run unattended/unmonitored — the only sensors are for homing, and the machine will neither know, nor care that a tool has broken, workholding has come loose, a part has broken free, or a fire has started.

I’ve tried using the McFly for clearing a large area for an outdoor sign and agree it didn’t provide ideal results, but with some changes to my approach it could have been better.

If I were to try it again, I’d create offsets around all the edges and let the McFly chew out the volume of material and then pocket the offesets and do a finishing pass or two with the more refined/appropriate tools.

That said, the trade off is ‘more area, less depth per pass’ vs conversely what you can do with a 1/4” mill and you’d still have to go back and clean up all the edges and bottom. Not sure the juice is worth the squeeze, as some say.

I use the “Winston” mod on the McFly, which is removing the bottom inserts.

It works much better. Surface finish is ok, not great.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.