Our organization is about to purchase the Shapeoko pro 5. Our main use is to engrave boardwalk planks. They are 5’ - 2x6, treated pine. We carve words with capital letters and simple designs on the boards. We’ve been doing these for years with hand held routers. The board orders just keep coming in and our volunteer can no longer keep up! We use new lumber but it does have some knots, imperfections and the occassionally wet wood. Can the machine handle this type of wood? Will we get a good quality finished plank? Does it take longer to cut this lumber? So many questions. Just want to make sure this is the best way to solve our production problem!

Yes, but you may want to do a bit of planning.

When I cut lumber which has imperfections such as knots, I like to take a photo of it, then use the Background image feature to bring in the photo onto the correct size stock, then arrange the cut so as to take the best advantage of the knot placement.

You may need to work with the feeds and speeds a bit to improve throughput over a person with a router template — do you have an image of them?

There’s at least one font based on router templates:

Welcome to the Shapeoko community! The Shapeoko 5 can definitely handle treated pine. There are two things I would worry about. Although the machine can handle the wood, you’re going to want to be careful about the knots, as Will suggests above. You are also going to want to be very careful about dust management, as your wood may have been pressure treated prior to the time where heavy metals were prohibited in this use. Starting in 2004, arsenic was banned for pressure treating woods, but unless you know precisely what was used, I’d treat the dust from this sort of operation as hazardous. You’ll probably want robust dust collection as well as providing some sort of respirator for the person running the machine.

If this is treated wood I have done a lot of outdoor furniture projects with an SO3. The SO5 is a much more rigid and stronger machine. So the short answer to your question is YES. Now wet wood is hard to carve with any thing like a hand held router but the SO5 should hand it faster and better.

Not sure how you carve your material now. I would suppose you make a template to route out whatever you are making. So the template is no longer physical but in the software. You can reuse or modify your files in seconds and save and start running them.

The SO5 can have the 1.25 HP router or your own VFD spindle or the C3D VFD spindle. The larger spindles that are 3rd Party or the C3D spindle is much more robust than the 1.25 HP trim router.

The SO5 can be 4’x4’ and all of that is usable. If you have to get the whole 5 feet routed then they have a new tiling feature that you cut the first part of the 4’ and move the material and complete the last 1’. But if the job will fit in 4’ then you simply have the board stick out on the front and back. Since the bed is 4’ wide you could fit multiple boards in and router multiple boards in one job.

The down side to using 2x6 material is it is not always 2x6. The measurement of 1.5" thickness varies and depending on your design you might have to either plane the material to a consistent thickness or simply cut deep enough to not have to rework any boards that are too thin. You could still do one board at a time and simply measure the board and set that up in Carbide Create or simply zero on top of each board and if it is not cutting through you could simply get a consistent depth no matter the board thickness.

So a CNC will speed you up if you consider the manual setup of templates and the clamping and routing. With the CNC there is no need for templates because the software becomes your template. You can reuse designs or make new ones in minutes.

There will be some learning issues at first but they are not insurmountable. We have people on the forum that never cut wood before to advanced craftsman. So your current operator can transition over in a matter of days.

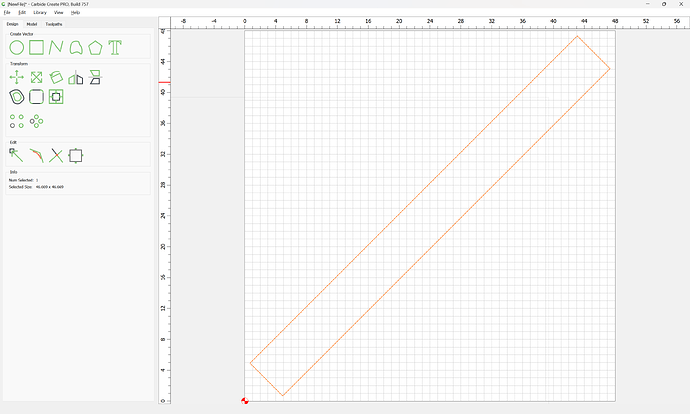

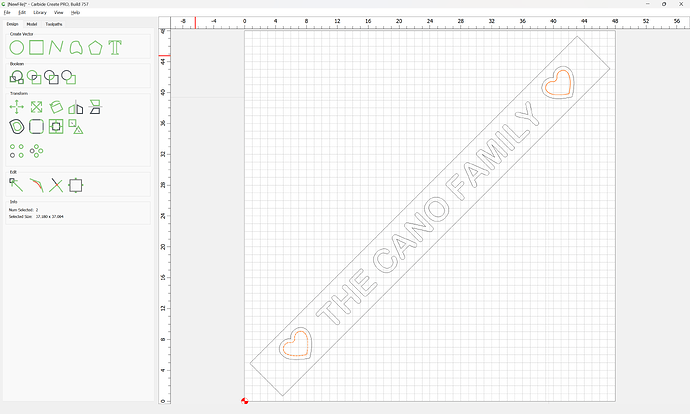

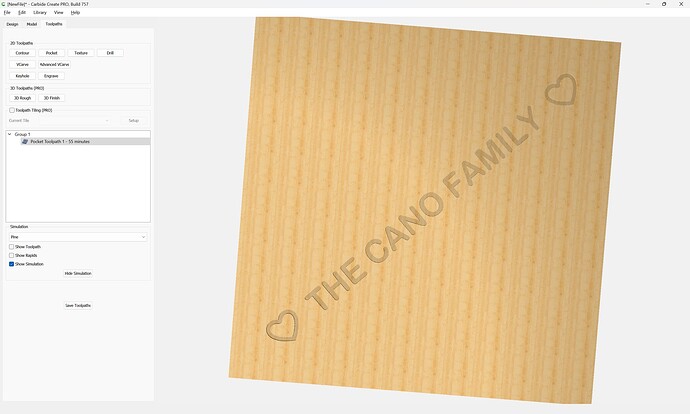

A 5’ 2x6 will just fit on a 4x4 bed if rotated 45 degrees:

As folks noted, how the wood was treated is a potential safety/health concern (though arsenic as was once used is no longer allowed in most places if at all), and how dry it is will determine how well it will cut.

Do you have a photo showing an example?

Never thought to go diagonal. That’s Brillant!

Here’s a few photo of planks with knots. They’re between routing and finishing so still a little rough.

Charming!

Those should be quick to lay out w/ a suitable font.

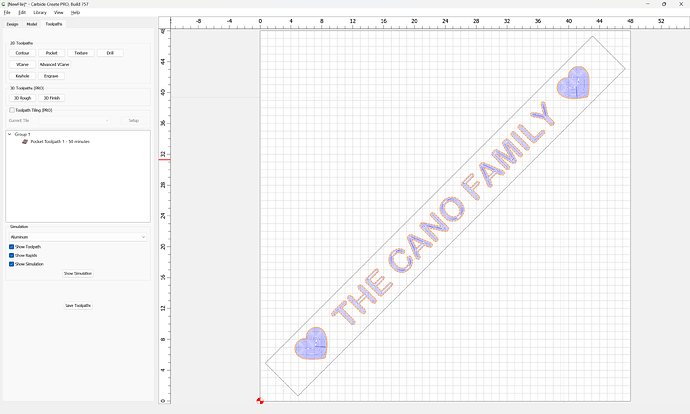

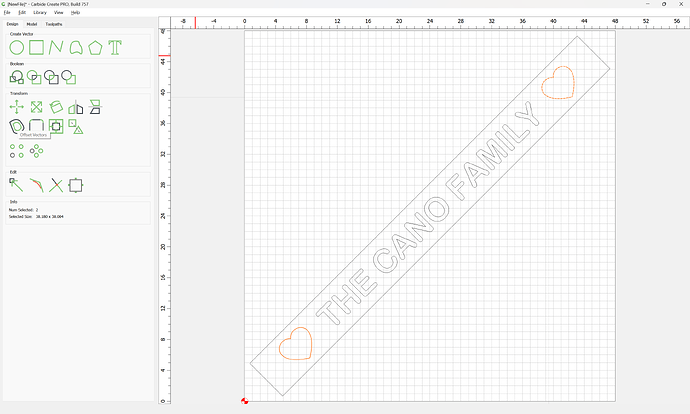

Something like:

The text was set using Arial Rounded Bold, while the hearts were pulled in from bundled clipart.

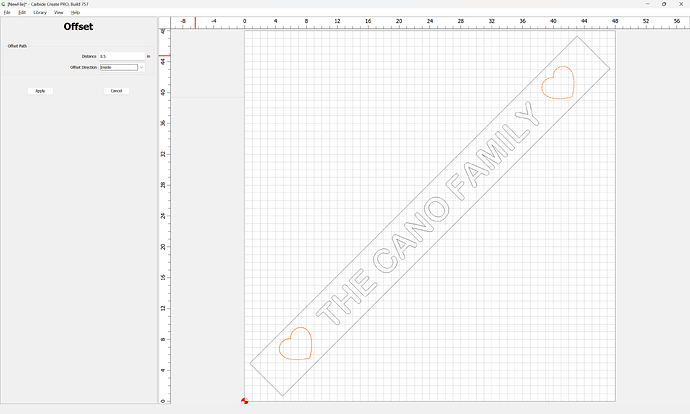

If you inset the hearts:

You get:

attached as a v7 file

the_cano_family_hearts.c2d (216 KB)

Not sure if it matters for your projects, but make sure the grain of the wood runs the way you want it when orienting the stock at a diagonal.

Here is an example of what can be done with lumber. This is a cedar 2x6. I used a 60 deg V-bit. In this example, the carved piece is 70" long which is too long even for a 5Pro like mine so I had to do it in two stages.

That looks great. Once we have the machine and software figured out we’ll be carving bench backs as well.

How computer literate is your “volunteer?” If you are limited to that volunteer, perhaps download the free software from C3D and let that person train on it while you observe, before you commit too far.

There is actually a few of us taking on this new adventure. We’re a fairly computer literate bunch. We each have different strengths so we should be able to figure this out. The learning curve will be interesting. I’m working on CC. The basic graphics part was easy. Now I’m struggling through toolpaths and layering!

This topic was automatically closed after 30 days. New replies are no longer allowed.