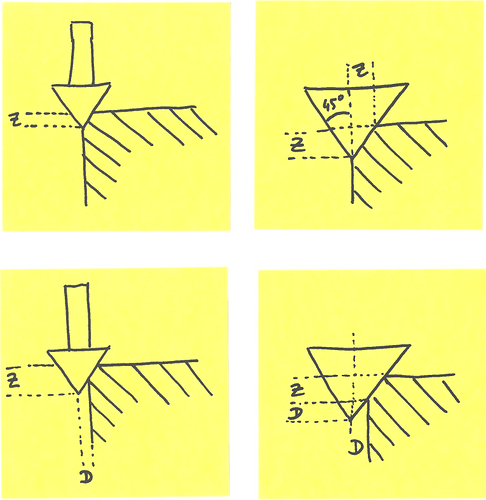

I’ll add that technically the point of a (perfectly pointy) vbit has a cutting speed of zero, which is not great for cut quality. So sometimes it is worth offseting the contour toolpath by a certain amount, and increasing the Z depth accordingly, such that the chamfering action happens using the “middle” of the vbit cutting edge. For a 90deg vbit the compensation is easy (for other angles you need to throw some more math at it)

But then again, in wood it does not really matter and the simpler approach of just following the original profile works.

If you can tolerate a little bit of rounding of the inner corners of your hexagon pocket, a profile toolpath (offset or not) will do.

if you need perfectly sharp inner corners, then you could do the chamfer as a vcarve op, creating an inner offset profile (offset inwards by twice the depth of the chamfer) and use that and the original profile as the boundary vectors for the vcarve.