Greetings, I have owned my XXL for several years now and have made several great projects. A couple of months back I was cutting some oak clamps for my machine and had a crash resulting in a 1/4 inch endmill doing a deep dive into my waste board. I noticed my router making a rattling noise after this crash yet it still cut good. I discovered the rattle was due to me busting the bottom bearing housing and cracking the bottom. It was the Carbide router by the way.

I had a project due so I had to replace to replace the router with one i picked up from Lowes. The new router is a Dewalt 611. My problem is the differance in the cord length. What are some suggestions on extending the cord length.

Thanks,

Brett

The usual way to handle this is to run an extension cord up to the ceiling and secure it there, then to run the router power cord up there and secure it so that the plug end and the extension cord won’t move.

Thank you Will for the response. I will start looking at how to hang the cord above my machine. thanks.

I assume to swap the 611 router you had to replace the mount?

If it is a SO3 the mount is 69MM with a 66MM insert that came with the belt Z. If it is a later machine then you do need a 69MM for the Dewalt. Not sure what the Z-Plus had on it for the SO3 when new likely a 66MM for the C3D router. Definitely the SO4 and above have a 66MM mount by default.

No, I just did not use the insert that came with the carbide router. The 611 dropped right in without the insert.

I have an SO3 and I upgraded to HDZ. In the beginning of the SO3 they had the Belt Z axis. I reused my original router mount that was a 69MM from my Belt Z when I upgraded to the HDZ 3.2. When the SO3 first started selling they sold the Dewalt 611 router. They offered the adapter for the 66MM Makita. My SO3 came with a Dewalt and the 66MM adapter was boxed in the packaging. Eventually C3D started selling the clone of the Makita which is 66MM. The C3D router is manufactured for them and the standard Makita clone version and a variant with an E11 Collet which is the same router as the standard C3D router with a different router shaft that uses the ER11 Collet.

The Z-Plus came with the 66MM standard and you could buy a 69MM mount. The Z-Plus has been standard for some time on all C3D machines for SO3, SO4 and the Pro models. You could upgrade all of them to the HDZ and either reuse your existing router mount and router or buy one of any size you want, 66MM, 69MM or 80MM. The C3D/Makita use the 66MM. The Dewalt uses the 69MM and the 80MM is for spindles. C3D does not recommend a heavy spindle for the Z-Plus. C3D would prefer you to upgrade to the HDZ if you want a heavy spindle. Some have reported that the air cooled 66MM spindles will work with a Z-Plus but the 80MM water cooled spindles are likely too much for a Z-Plus.

For the history buffs the original HDZ was created and sold by Mr Beaver, aka Luke of C3D. Luke is from the UK and sold and built his HDZ, Mr Beaver. Later C3D hired Luke and started selling the C3D version of the HDZ. There are still some of the original blue Mr Beaver Z axis still in action out there.

The original Edward Ford models of the Shapeoko 1,2 and 3 had a belt driven Z axis. Later the Z-Plus Leadscrew driven Z axis was designed, developed and sold and is the current standard Z axis on most of the C3D machines. The HDZ is optional on the SO3 and above machines.

Short history of Shapeoko routers, mounts and Z Axis from C3D.

Edit: Per @WillAdams

Actually the Shapeoko 1 and 2 used an M8 threaded rod (and there was an optional leadscrew upgrade from the user, “Improbable Construct” which I had on my SO1) — the belt-drive Z-axis was an innovation for the Shapeoko 3.

You could take the cord off the Carbide router and put it on the DeWalt.

Actually the Shapeoko 1 and 2 used an M8 threaded rod (and there was an optional leadscrew upgrade from the user, “Improbable Construct” which I had on my SO1) — the belt-drive Z-axis was an innovation for the Shapeoko 3.

I looked into that; however the power cord on the Dewalt has three wires, a white, black and a small control wire for the speed control. The xarbide is only a two wire cord. Good idea though.

I had the same issue when changing a router. I just cut the cord off the old router and left it on the machine. Then cut the cord off the new router and left it a bit long in case i ever need to rewire it again and used some connectors to tie the two together.

Should just be two. Where would the speed control go?

Maybe I am missing something but the Dewalt has 3 wires, hot neutral and ground. The Makita/C3D has 2 wires hot and neutral. There are two types of 120 vac. Appliances that are grounded (Dewalt) and Makita/C3D which are double insulated with no contact with electrical unless something goes terribly wrong. Lamps usually have 2 wires where many small appliances have 3 wires where the chassis is grounded. The Makita/C3D routers do not ground the chassis. These types are UL rated for what type they are and that effects physical construction of the device.

If you guys are sure, maybe they’ve changed something at some point. I am sure that my DWP611 is double insulated and uses an 18/2 cable. I had to change the cord after letting a neighbor borrow it.

Pretty sure it’s the same cable on my old corded drill too.

Dewalt 611 - at least in the US - is a 2 wire:

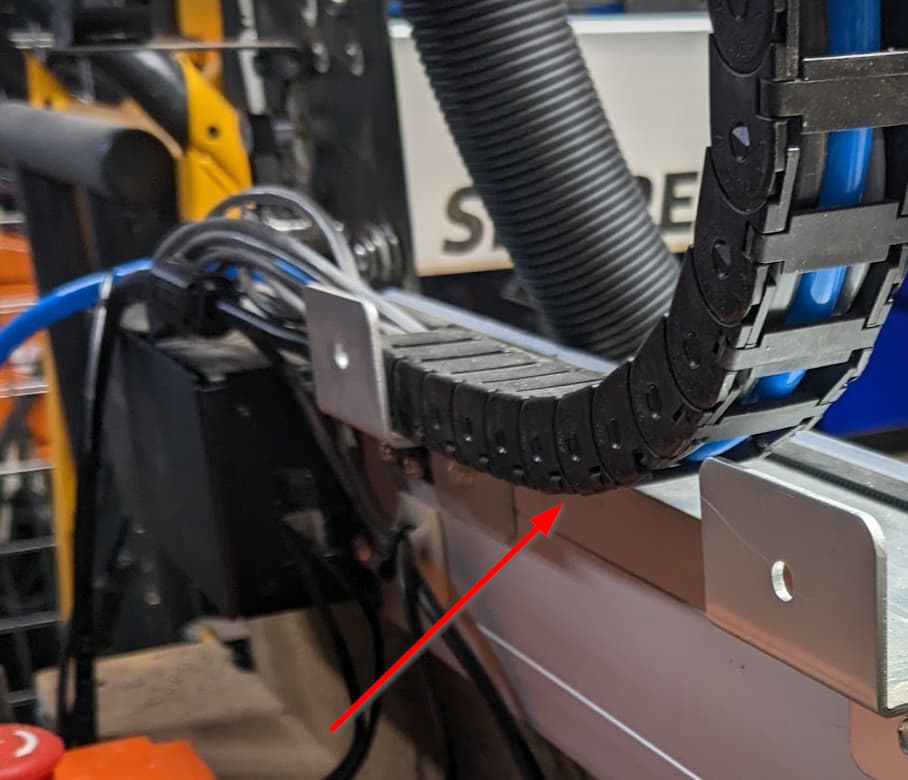

Internally it is split off into several controls, including the lights, the speed, etc. On my 3 XXL, it was plenty long enough to get through most of the drag chain. Popped it through on the bottom about 8 inches early right after the drag chain bend and put it on an extension cord. I had already swapped to the spindle when I took this photo, but the arrow points to where it had it coming out.

I stand corrected. I was running my Shapeoko at the time of posting and could not unplug it from the BitRunner. The double inslated appliances only have a 2 prong polarized plug. My appologies.

Not sure i watched a video on changing the cord and it had three wites. I will try to find and post a link.

At least one person on the old Shapeoko forums defeated the double insulation of the tool to ground it in a traditional manner in an attempt to resolve EMI issues.

Please don’t do that.

Trust me i am not trying to ground the router. I am liking the idea of mounting an overhead cord and connecting it to that, or placing the cord on my vaccuum hose arm that moves with the machine.

You could buy the cable by the foot and make your own power cord…just don’t go with an excessive length.

For those that may be interested. This is the symbol for a double insulated product.

Thanks @dandangerous for the pic.