Did you intentionally leave PD001 at 0 and set PD002 to 1 ? (which would mean: start/stop is still manual at the VFD but speed is from the PWM)

You should probably initially set PD001 and PD002 to 0, modify all other values, connect everything, test that manual operation of the spindle works fine from the VFD knob, and then change PD001 and PD002 to 1 to let the Shapeoko/PWM control it.

12sec acceleration/deceleration sounds like a pretty slow speed rampup, which is fine in itself but just a word of caution: once you proceed to use the spindle/VFD controlled by G-code, make sure to include delays in your Gcode after the M3 commands, or you will be in for a bad surprise (= the endmill plunging in the material while the spindle is still accelerating towards its target RPM)

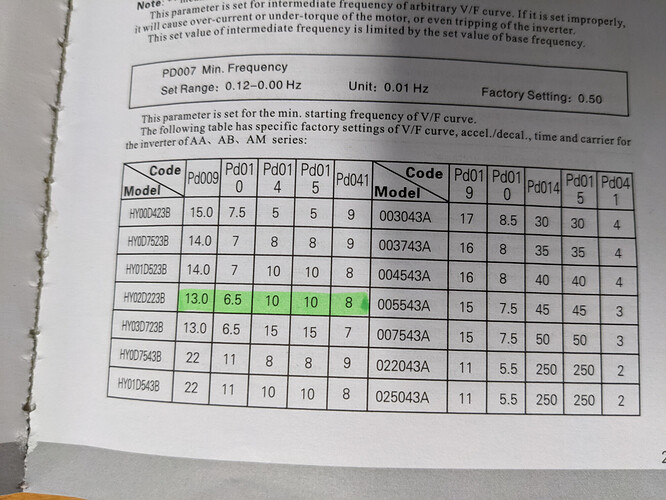

Params 9/10/41 could be taken from your VFD manual, mine has this table with values depending on the specific VFD model,

but I ended up using 15 and 8 (mentioned as the default/factory values) instead of 13 and 6.5 and nothing exploded…

Fingers crossed, let us know how it goes !