I was making a shallow tray by using Contour and Pocket and then an outside offset to cut the piece out of the stock. Both the inside edge of the pocket and the outside edge from cutting the part free are wavey.

Looks like the segmentation is too big. What software were you using. This is pretty easy to resolve by hand and save the part, but this looks like g-code not g-code interpretation (knowing how grbl does this, it would have to have had ut’s approximation settings messed with, which is unlikely)

Carbide Create and Carbide Motion.

What is meant by segmentation?

a circle is turned into small linear segments… if those segmets are too large you can get what you see in your picture. More segments reduces it obviously

There is another effect possible (but this would be directional): The stepper motors have a 0.025mm step size, which can be seen if you cut, say, polycarbonate under an angle

visually this looks a bit like either the stepper motor thing or some resonance

have you ever tried doing a finishing pass?

(e.g, cut out the design with an outside-offset of say 0.01" and after that is done, do one final cleanup pass at full depth on the original contour, basically shaving off that last 0.01")

I have not tried a finishing pass.

I have made similar cuts before without having the effect. The outer edge and the inner edge were both smooth. Could something gotten “out of whack” causing the motion of the x and y axis to be less fluid.

Can you upload the G-code file for a quick double check that there is no visible segmentation there ?

What cutting parameters were you using, including depth per pass ?

A datapoint:

-

a ~32" circle (actually 16.0078 radius) in Carbide Create will be cut as a series of 1024 straight-line moves of a bit more than 2.63mm length:

X-406.59Y-2.63

X-406.60Y0.00 -

a 2 in. circle will be cut as 256 straight line moves of a bit more than 0.66mm length:

X-25.39Y-0.66

X-25.40Y0.00

Interestingly, if one converts a ~32in. circle into a polyline using a Boolean operation one gets the same 1024 movements, and of course, if one reduces that polyline to 2in. diameter one gets movements of ~0.17mm, though interestingly CC discards some Y-axis movements as too-small:

X-0.16

X0.00

So if there are facets which are too large with native circle/curve elements a solution is to enlarge them greatly, perform a Boolean operation, then re-create the toolpaths.

However, if you get a file which uses circles/curves which does not cut well, with such visible faceting, please send it in to us at support@carbide3d.com and we’ll try to have a developer look into it.

I’ve had that once after a crash and I had to retighten the v wheels…

worth checking if the wheels and belts are “tight but not too tight”

I will check the wheels and belts as well as send the file to support. Thanks for the advice and support.

One factor producing segmentation is whether you’ve enlarged the SVG within CC.

If the object in question is a polyline.

Circles and curves should enlarge w/o loss of quality.

here is the code

cutout Wafford.nc (272.8 KB)

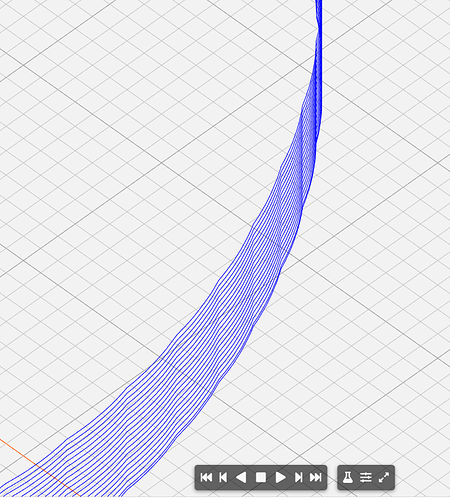

Interestingly, the problem is there in the G-code, and it’s not even linear segmentation, it’s a sequence of “bumpy” arcs:

So the good news is there is probably nothing wrong with your machine, and you should look at how you created the CAD instead. Did you draw a circle in CC or import an external SVG file ?

We would need to see the source file(s) — also notes on how it was made.

I believe this one was a SVG I imported

If you happen to still have that SVG upload it and we can check it, the problem might be there, and/or maybe it was exacerbated by scaling it. Or upload the c2d design file for a look ?

This should only confirm that this is not a milling artefact, but a CAD problem.

Circle.c2d (874.3 KB)

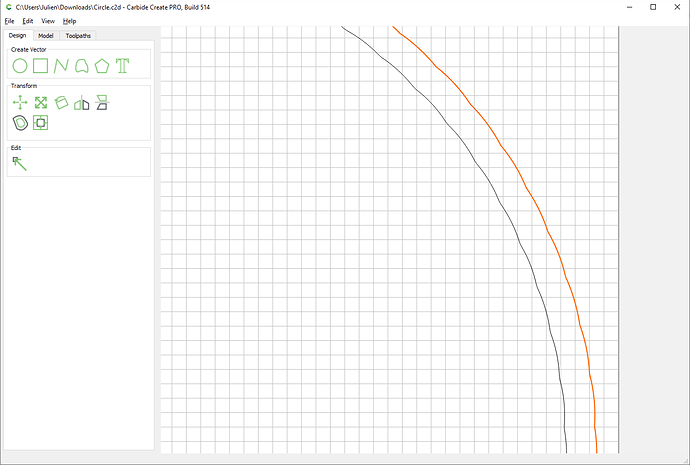

Yep, the problem was there in the design file already:

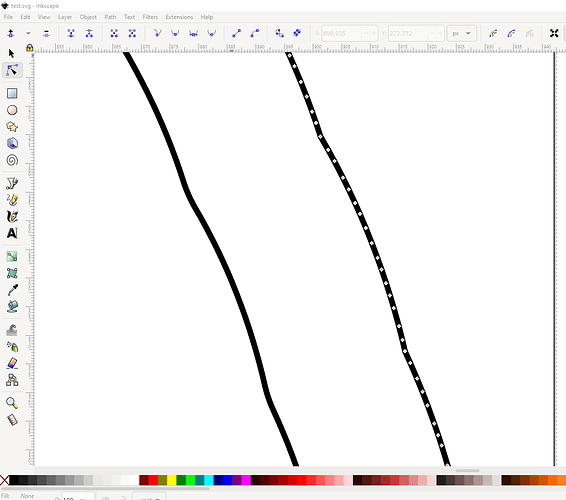

If you open the vector in Inkscape you can see how the “circle” is actually made of hundreds of tiny segments, with the periodic bumps

Mystery solved then, the original SVG you imported was not smooth. You can just redraw an actual circle in CC instead

Thanks guys. At first I thought my machine was messed up. Learned a valuable lesson. You guys are the best, as is this community.