@Vince.Fab Did you ever put that MDZ into action? Any more details you can share?

LinuxCNC supports pretty well any setup, I’ve seen it configured to use both the encoders on servos) and a glass scale to maintain accuracy. Probably a little more than the ol shapeoko warrants!

I crave a bigger more rigid machine, but I don’t think the SO3 needs to change, there are refinements that could be made but to me it’s positioned quite well in the market

FYI: Tormach is introducing servos on the PCNC 770 (and 1100, I believe?) If you’ve got the cash…

[quote=“BartK, post:40, topic:17482”]

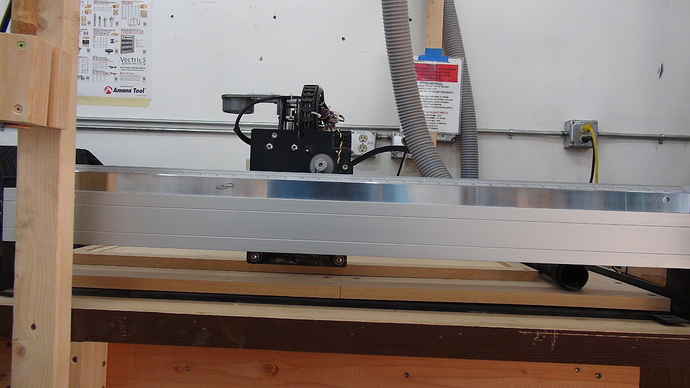

I’ve reused so3 xl’s long extrusion as a gantry on my cnc, but turned out to be nowhere near as flat as i need it be?

How flat do they need to be?

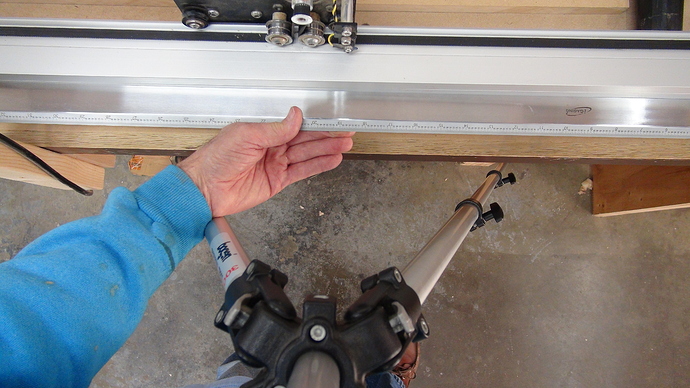

My extrusion has a slight bow. I tried Installing linear rails on both front and back faces and all my ‘straight lines’ in the x direction weren’t straight. Thought the problems were the linear rails, or maybe a debris under the rail, but straight edge confirmed my worries. Right now, it’s like only 3/4 of the entire cutting space is actually usable. Doesn’t really matter, maybe it’s just my OCD and it wouldn’t make a difference to somebody else, but it simply annoys me. I surfaced my aluminum wasteboard by cutting a pocket and then checked all the inside edges with a straight edge. Both edges along the shorter (y) axis were perfectly straight, and both longer (x) edges had a bow - one side was concave, while the other convex… That literally has to be extrusion that is a problem. Besides, we don’t really know what are the tolerances that those extrusions are made to. That’s also why Misumi sells extrusions with milled faces, or why higher end machines use milled channels to install linear rails. I just got unlucky, that’s all.

I really hope (for your sake) that you’re not as OCD as I am! What tolerance does Misumi claim for their milled faces?

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.