I designed a project but when I run carbide motion, the program doesn’t recognize my cnc. it says “cnc not found” . I have the cnc turned on and connected via usb. am I missing something or will carbide create only work with the shapeoko cncs?

Carbide create can export gcode that other CNC’s can recognize (GRBL based CNC’s though I think).

Motion, I think is used for Shapeoko/Nomad. I’m not aware of anyone using them for other CNC’s. You may be able to grab a different gcode sender/controlling software. There are a bunch listed on the shapeoko wiki.

Which CNC do you have?

Carbide Motion will only connect to a Shapeoko or Nomad (it looks for a specific USB deviceID/vendorID)

Carbide Create can indeed still be used to generate Gcode, but a generic gcode sender will be required to feed it to non-C3D machines

Check out Universal Gcode Sender: https://winder.github.io/ugs_website/

And when you want something better, check out CNCjs.

![]()

l have only had my millright mega v cnc for a week or so. How do i generate a g code with carbide create that will work with my machine? I’ve created a project and if I don’t use carbide motion, how do I send it to my cnc? Sorry for sounding so helpless but I guess I am sort of helpless. If I go to the universal g code sender will that make the connection?

I have a millright mega v cnc. I’ve been trying to find a good (easy to use) program and I like the carbide create but it isn’t much good if I can’t get the program to connect to my machine. Do you have any suggestions about other programs I should consider? I don’t mind buying something but only if it will work.

I went to the universal g code sender website but I’m not sure what to do next. Is there anyplace that might give me some guidance?

Hey @abushy1 ,

There are two steps in the CNC workflow:

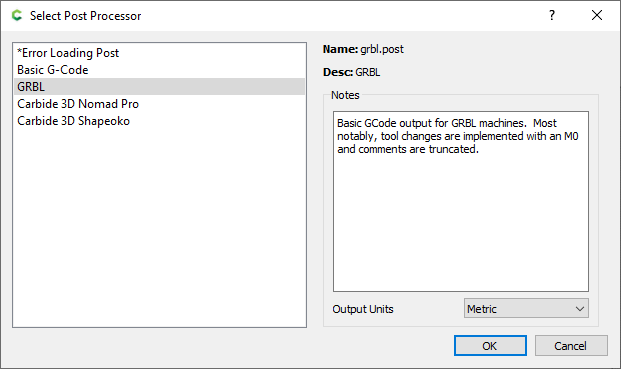

a) designing parts and toolpaths in a CAD/CAM software to generate G-code for the machine. Carbide Create is one such CAD/CAM tool, and it will produce G-code file in several formats for different machines, through what is called a “post-processor”. In Carbide Create, for a non-Carbide3D machine like yours but than still runs GRBL software on its controller (like yours does), you can select the “GRBL” post-processor in the Edit menu, “Select Post-Processor” sub-menu:

b) sending G-code files to the machine to actually cut material. This is where you need a G-code sender software. Carbide Motion is one such tool, but as mentioned previously it will only work with C3D machines. Universal G-code sender and CNCjs are two popular generic G-code senders, and by generic I mean they will talk to any CNC running GRBL (and more).

You will need to check out the UGCS or CNCjs websites for documentation, but more importantly you will need to learn about the general CNC workflow to understand what to do and when. Understanding how to use the G-code senders is very easy…once you know what all those terms mean. Things like jogging and setting zeroes at a specific location before running the job.

Considering you bought a millright cnc you should probably look at their forum (mentioned on their faq page), for specific help on running those machines. You can still get help here about using Carbide Create of course.

This topic was automatically closed after 30 days. New replies are no longer allowed.