We needed to dress up the steering wheel of a vintage drag racing car from the late 1950’s. After putting together a tilt wheel and installing it, a brass blank was turned on the lathe and it needed an emblem. We wanted to mill something like a 1938 Ford truck emblem into the brass and I thought the Shapeoko could do it.

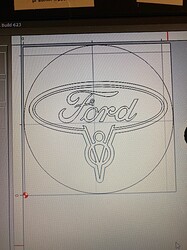

I was unable to find a decent emblem so I had to merge the typical oval Ford emblem with a V8 emblem in Carbide Create. After alot of resizing, node editing, and boolean magic, I ended up with the following.

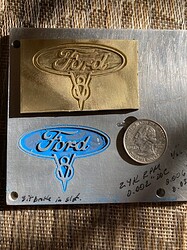

The brass piece is just over 2 inches in diameter and milling it required a 1/32 inch end mill to give the detail I wanted. This was the first time I had cut metal on the Shapeoko so I ran three test cuts in aluminum and one in brass. I had success with the first two tries in aluminum while modifying the design. Parameters were 24000 rpm, 20 in/min feed, 0.002 in depth, 0.006 in step over, total depth of 0.030 inch. Then broke a solid carbide bit in a deep slot and moved into brass. In brass, 10000 RPM, 10 in/min feed, 0.006 inch depth of cut, with a 0.006 inch step over quickly broke another bit. Switching back to my original parameters after designing a pocket in place of the perimeter slot gave a decent cut in brass.

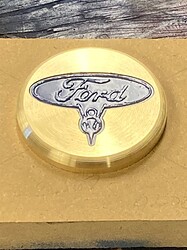

To paint the background, I tried acrylic paint which rubbed off (seen on the aluminum test cut), and fingernail polish which was marginal. I decided to try Oramask 813 on the real cut and spray paint. To hold the brass piece, I milled a friction fit pocket in scrap MDF and clamped the MDF to the wasteboard. While milling, I did pause a few times until the mask was cut through, to clean mask from the bit. I was watching this with a magnifying glass. It did cut successfully but tiny shreds of Oramask required removal before the paint. Here is the piece painted and partially unmasked while the paint dried.

And the latest after pulling all the mask off with a safety pin.

Looks great but stilll needs some clean up. It is definitely going on the car!