So, you close feeds when they don’t suit you? Sounds like a dictatorship, to me.

My response to that thread was going to be…

They’re all very valid points, @Gerry, and I appreciate the feedback.

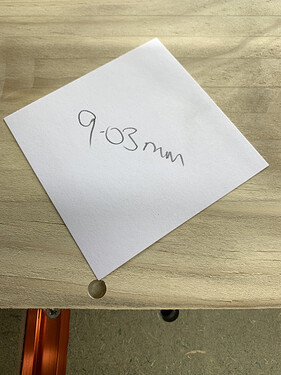

Being a) trained to follow orders in the military, b) an engineer by trade, c) follow instructions to the letter by profession, and d) old and set in my ways, I’m confident I’m doing what I’m supposed to do, but here is my process, with the computer on, CM not running, everything connected, and the machine switched ‘off’ and in the NE position (which is where I normally park it):

- Secure the stock in place.

- Turn the machine on using the rocker switch.

- Start CM.

- Click ‘Connect to the router’ - then wait for the Initialise button to appear.

- Click Initialise - The machine homes, moves to SC prompting for a bit/probe.

- Click Resume - It does its thing with the BitSetter, then returns to SC.

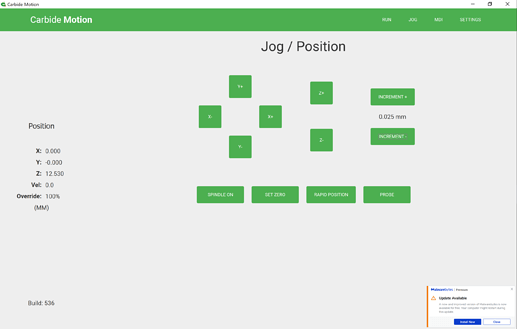

- Move the spindle to the start point and, using the ‘automatic’ CM workflow with the BitZero v2, set the X, Y and Z zeroes and remove the BitZero to a safe place.

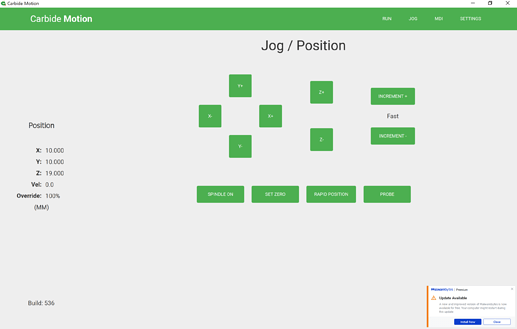

- Move the spindle to an approximate SC.

- Load the *.nc file.

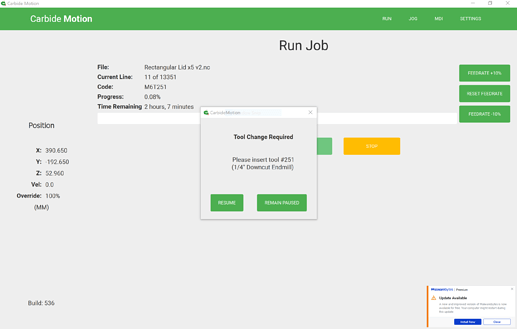

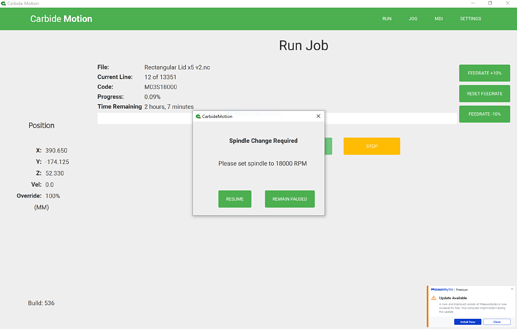

- Click Run - CM prompts for a new tool.

- Change the tool (unless it’s already in the spindle).

- Click Resume - It does its thing with the BitSetter, then returns to SC.

- Click Resume - cross my fingers and hope for the best. It’s at this point it going to go right or wrong.

This is the process I follow every time I start the machine to run a project but, if I run another project during the same session, I start the the process at Step 6, even if I’m running the same project a second time and cutting from the same stock.

I’ve tried this today, following these steps, and the project seems to be going well. I’ll let you know when t’s finished, but if these aren’t the ‘approved’ steps to follow, I need to know.