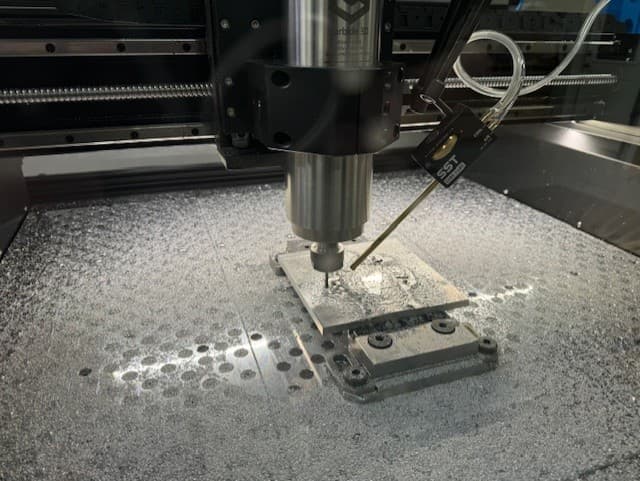

I’ve been working on my aluminum carving skills and have run into a rather annoying problem.

I know there are efficiencies I could improve with my file, but it is a 14hr roughing pass of a 3d carve output from CarveCo.

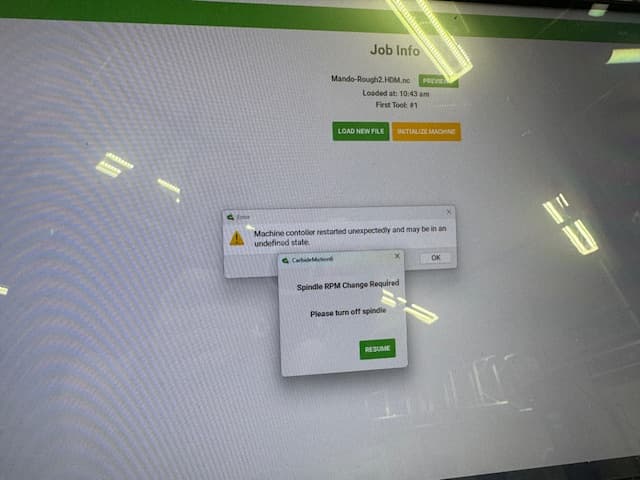

Roughly 6hrs in (don’t know exactly) I turn around and see the controller restarted unexpectedly and it’s in an undefined state.

I did the only thing i could do which is to hit resume but that screen went way… then hit ok on the error message.

I’ve validated the X, Y, and Z are all still set correctly, but I have no way to restart the file at X percentage.

How do I fast-forward through this file to a point I believe it died at in order to resume where I left off?

Out of all of the things I’ve done with other machines, this HDM is still fully stock.

I’m a programmer and can read gcode but the proper sequence of events to recover from something like this is not as clear.

I assume i’ll have to edit the original gcode file… but what exactly do I cut out?

Here’s the start of the file, at what point to i start snipping commands till i “think” it’s somewhere close to where it left off?

And will the machine simply move to that exact location and resume?

(Mando-Rough2.HDM)

(STOCK/BLOCK) (X=6.000, Y=6.000, Z=0.470)

G90 G94

G17

G20

(Tool Number:1 0.145 inches dia. slot drill)

G28 G91 Z0

G90

T1 M6

S20000 M3

G54

G0X0.0000Y0.0000Z0.5000

(Rough2)

G0X0.7778Y0.0000Z0.5000

G0Z0.5950

G1X0.0000Z0.4579F5.0

G1X6.0000F10.0

Y0.0577

X0.0000

Y0.1154

X6.0000

Y0.1731

X0.0000

Y0.2308

X6.0000

Y0.2885

X0.0000

Y0.3462

X6.0000

Y0.4039

X0.0000

Y0.4615

X6.0000

Y0.5192

X0.0000

Y0.5769

X6.0000

Y0.6346

X0.0000

Y0.6923

X6.0000```