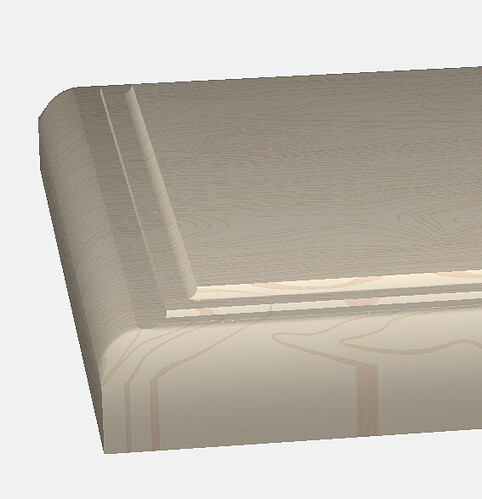

I am wondering if anyone has tried to use the CNC to copy or mimic drawer front profiles? I have added a couple of cabinets to my kitchen and have 4 new drawers and want to match the old drawer fronts. I have had no luck in finder the specific router bit that makes the profile (custom one I am thinking). So I thought maybe the CNC could mimic it. Anyone have some helpful tips? I am a beginner on the 5 pro. Below is the profile I am trying to mimic. The left is the back and the right is the front. Thanks

Got pretty close. 1 3D path for the rounded outer edge, and several 2D paths…

Here’s the file if you want to take a look.

Drawer_Front.c2d (464 KB)

The back (drawer pull) could just be done with a 30° chamfer bit.

There’s a good chance 2 or more router bits have been used for that profile based on how old the draw fronts were. I have matched several custom moulding patterns for older cabinetry due to no specific router profile being available. The best way to recreate this profile is to make a traced pattern and then match several different bits to match the profile. I have the 5 Pro and as a beginner myself I would be hesitant to try and create this profile. I’m not proficient in 3D cuts yet. Much easier on a router table as well as much faster due to needing to run a bunch of test cuts to dial in the profile. Not sure my reply helps your question, sorry.

Tod1d has made an excellent start for you however, cut enough test pieces in 1x3 material before cutting the drawer fronts themselves.

It’s very possible they were made with a custom ground knife/bit. Or it was a combo of a roundover, a rabbit, and a panel bit. Likely done on a router table / shaper.

The picture is hard to interpret. Years of wear & paint distort the original shape.

I can’t tell if the pull is radiused or a flat angle. I’ve seen both.

I worked in a cabinet shop out in California back in the 80s. One day doing doors & drawer fronts I was standing in a pile of sawdust up to my pockets in front of the shaper. ![]()

I have ground custom profiles, but it takes a while to get them right. So if you have knives to make it work it’s quicker.

Yes, custom bit. I know the guy who did our cabinets, they had a shop fire and it was a total lose. They had since retired the shop and have nothing for it. Thanks though.

Beginner here also, but a bunch of scrap wood to test. Thats part of the fun.

Thank you, thank you. If its close that I only know it will work for me. Again Thank you

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.