I am making a jackplate for a guitar and it is my first time machining metal. the screw holes are countersunk. Can I use a drilling operation and a countersink bit working with aluminum/copper? This is what I do with plastic for pickguards but didn’t know if it would work on aluminum. Any advice is appreciated. I am working in fusion 360.

Is the hardware metric or Imperial? For metric you can just use a 90 degree V endmill.

What speed is the maximum safe speed for the tool in question?

Alternately model the countersink in 3D and cut it as part of the 3D model?

A V-bit might work in aluminum, might not get you the cleanest edges but you can try it.

You can try sticking a countersink bit and plunging it straight down with a drilling op, but be mindful that the deeper you go, it’ll get exponentially more stressful on your spindle because of the increase in material you are engaging.

The two ways I would do it are:

Either with a chamfer bit (or V-bit if you’re daring) and chamfer toolpath, where it’ll zip around the perimeter of the hole instead of dropping into full contact instantaneously. Much easier on the tool.

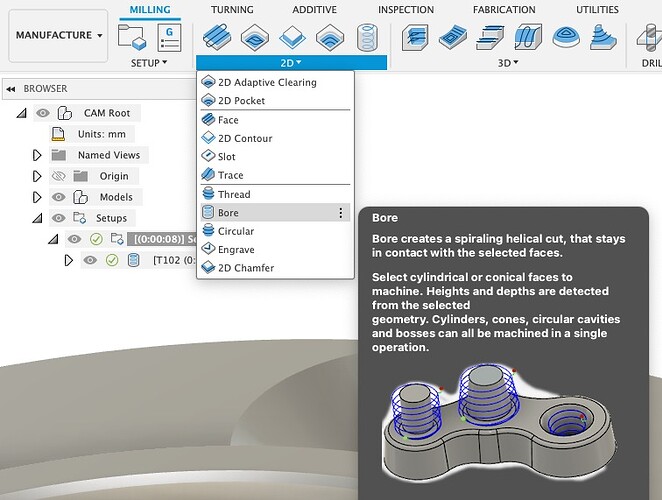

Or, use the “bore” toolpath, and select the tapered face of your countersink. Use a ball endmill, or heck, even a regular flat endmill to spiral down the face with a small pitch, and it’ll be nearly as good, and save you from needing a specialized endmill.

I don’t know the maximum safe speed for the tool. It’s just a standard Bosch countersink drill bit. I was thinking of just doing a drilling operation and adding the “peck” to it. Not sure what you you mean on the last part.

I thought about the ball operation, but the biggest issue is that I don’t have a ball endmill small enough for the hole (~2.25mm). The stock is only a little over 1.5 mm thick though, so I was thinking of doing the drilling op with pecking but still unsure if that would be very stressful on a standard countersink bit with a quarter inch shank.

As Winston says a toolpath that runs the countersink around the hole so you’ve only got a single point of contact is likely to produce a much better finish.

I’ve had pretty clean results using one of these in Aluminium and Brass, doesn’t say it’s for metals but it’s worked well for a few years now.

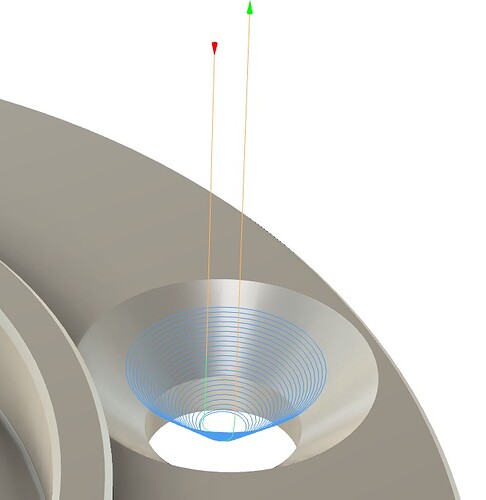

This is the toolpath I was referring to in the second part. It makes an endmill spiral down the face of any cylindrical or conical feature. Even if you don’t have a ball endmill, using a flat endmill will still get you a pretty good taper. If your spiral is very shallow, the steps between each pass will be nearly imperceptible.

I don’t think it hurts to try the countesink bit as a test on some scrap material, but I have a feeling it’s gonna screech and chatter. The minimum RPM on the router is still like 2-3x faster than a cordless drill, and I never get good results when I try to make a countersink at max speed.

Sorry Winston - the “second part” comment was for Will!

You need to know the specifications of the screws/bolts. Most are 82 degrees and some are 90 degrees. So the suggestion of a 90 degree vee bit would likely work for an 82 but it is best to match the angle of the head of the screws/bolts you want.

I did find that some aerospace countersink is at 100 degrees.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.