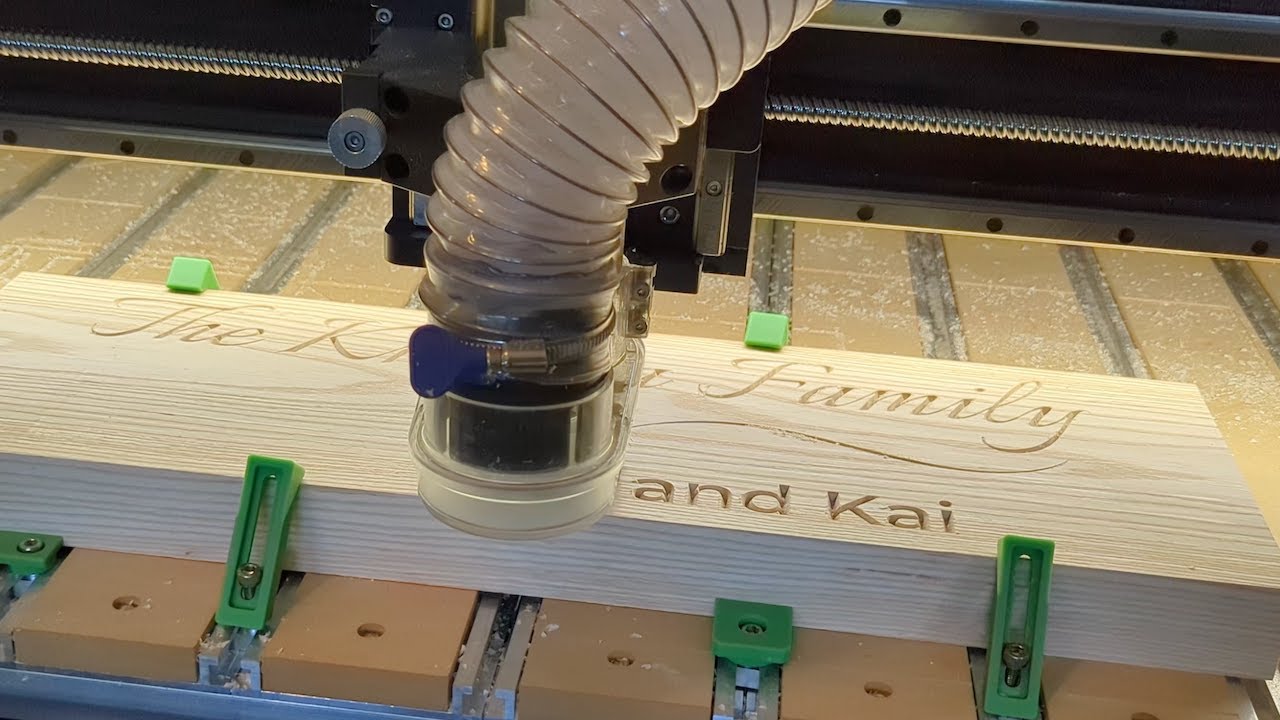

This started as a 2x10 piece of Spanish Cedar that was jointed and planed to thickness. Then it was cut on the Shapeoko 5 Pro using a combination of Fusion 360 and VCarve Pro. The carving was a 1/4" 60 degree V bit. The states were pocketed with a 1/4", 1/8", 1/16" flat endmills.

The brass token was also cut on the CNC machine with a 1/32" ballnose endmill and embedded into the swing seat with epoxy. Pigmented epoxy was used to fill the California and Michigan pockets, then sanded to a polished finish starting at 220 grit and progressing to 4000 grit.

All corners were fileted and then the wood was finished with Rubio Monocoat for a hard, matte finish. Nylon rope was used to be weatherproof and soft. It was twisted and stitched at the attachment points with nylon thread for strength.