In order to get a complete half-cylinder you will need to continue the shape past the edge as noted in:

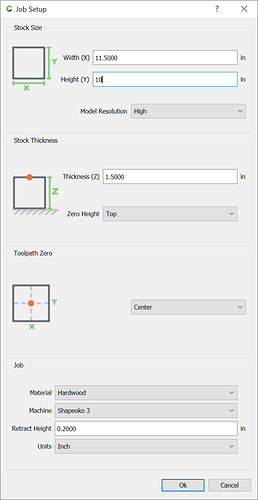

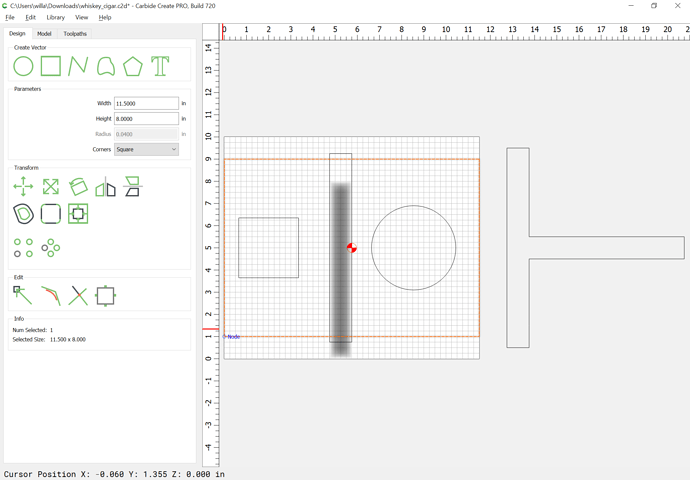

So increase the stock size:

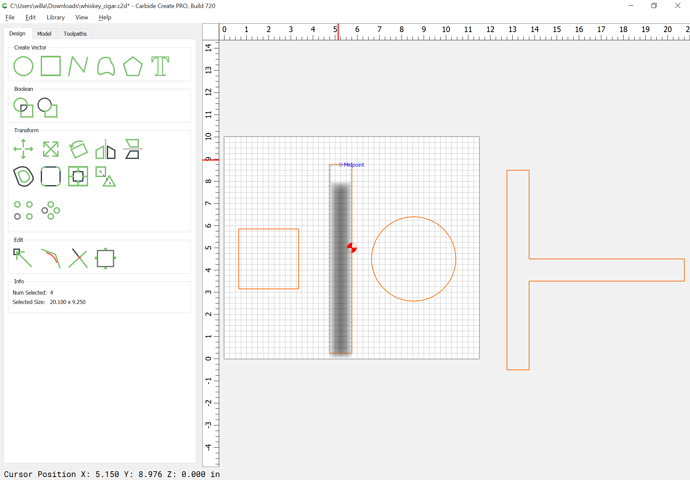

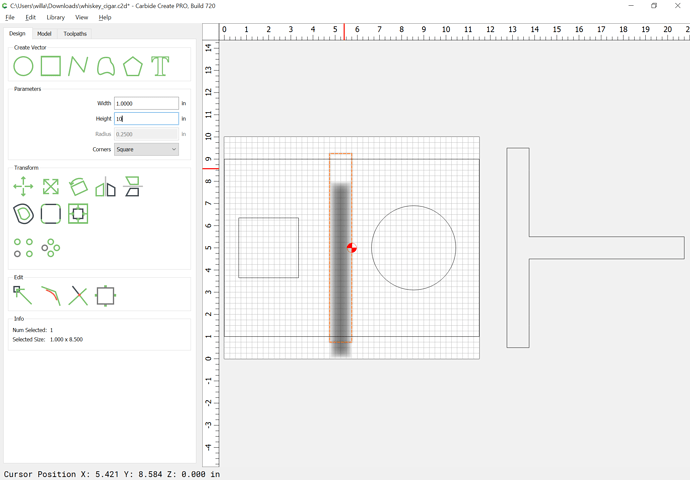

Align things to the stock:

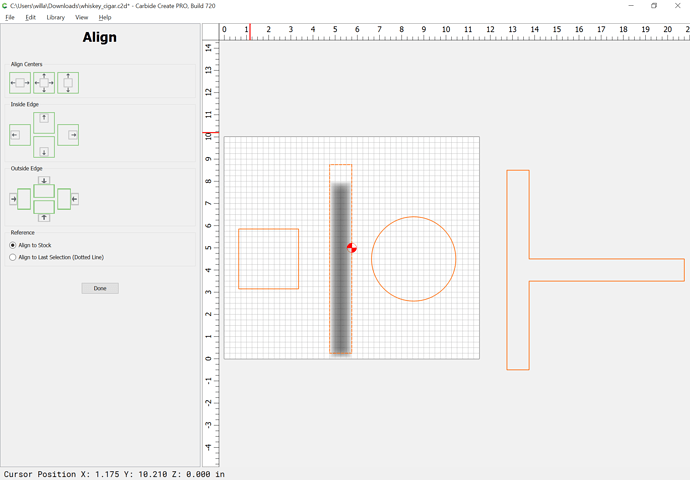

Draw in the desired area:

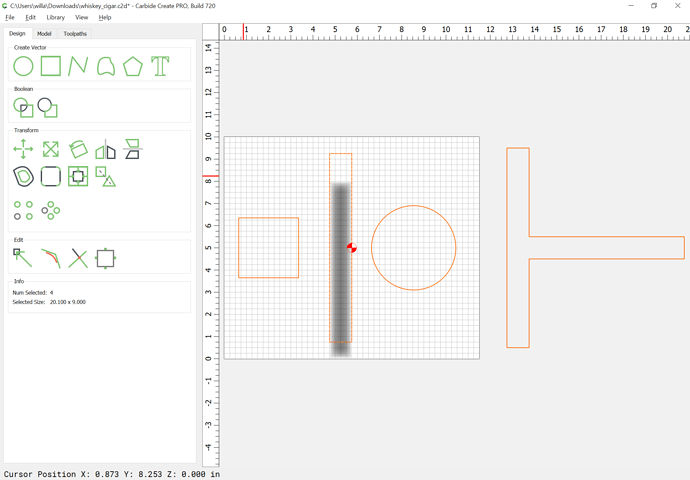

and increase the size of the cylinder:

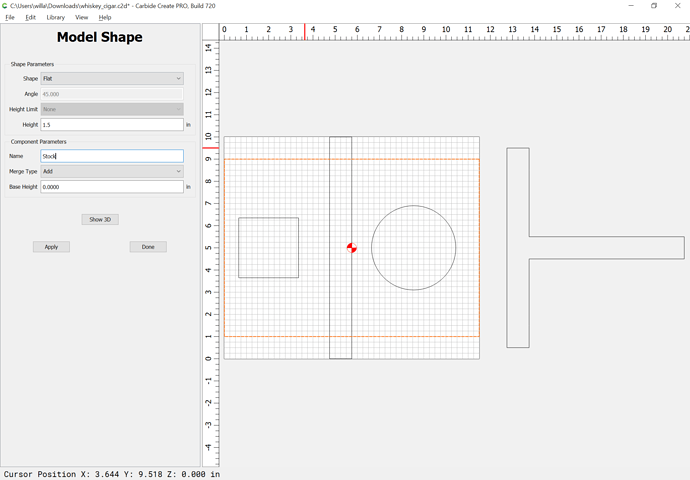

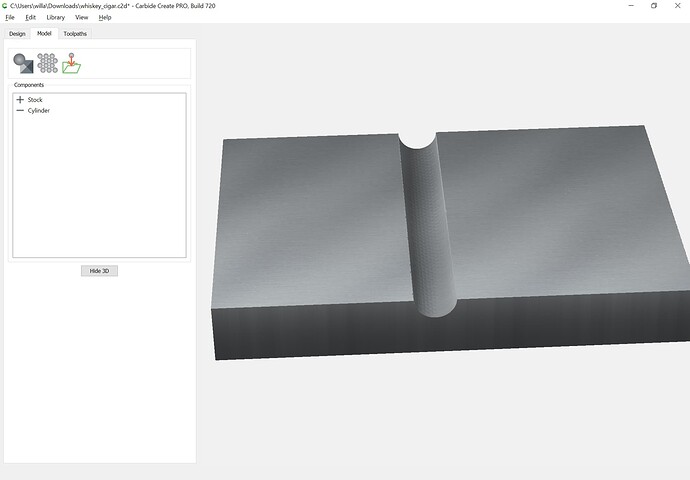

Then model the stock:

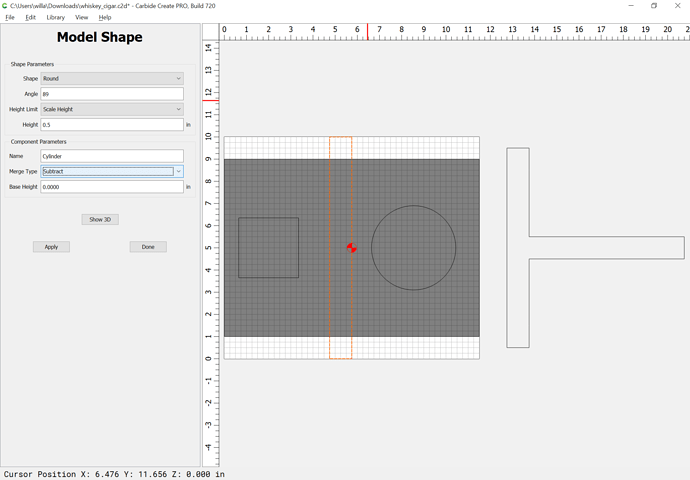

and subtract the cylinder: