What is the suggested tool, rpm and feed rate to cut 1/8" acrylic sheets in one pass as quick as possible?

What we have on acrylic thus far is here: http://www.shapeoko.com/wiki/index.php/Materials#Acrylic — more information / testing / cutting results would be welcome.

Thanks. I’ve checked that already. I was not able to find the answer to this particular use case there.

What machine are you using?

Can you post a picture of your file?

Often there are other factors to consider.

Gwizard says with a nomad, 10k rpm, .125" depth of cut, .125" carbide 2 flute endmill, 14IPM, 7.2 IPM plunge, for a very aggressive cut on acrylic. All I can suggest at this point is use that as a starting point. Go too slow, and you’ll get a lot of melting. Either way, depends on the surface finish you want.

Thank you for your suggestion! I’ve read that 1 O-flute endmill is suggested for acrylic. Would you agree 1 O-flute is better?

My newbie “trick” for guesstimating feeds and speeds for materials is to ask Carbide Create to cut that material with that tool, even when I am really cutting a design made in different CAD. Had no trouble at all cutting (on Nomad) an acrylic design from Openscad, sent through Meshcam, using CC’s suggested feed, plunge, etc.

Hard to tell, haven’t done it myself, but I wouldn’t go investing in an expensive endmill until I had done some experiments. If you’re interested in maximum speed cut, sounds like you’ll be doing a lot of this, and if that’s the case, it’s worth it to experiment a little. With Nomad (don’t know what you’re using, shapeoko or nomad) I think gwizard is a little optimistic. I really wish there was a great library of speeds-n-feeds, but there isn’t. It depends so much on the exact endmill you’re using (onsrud != cheap chinese != victor != …) the best that seems possible is to get close with a calculator and tweak from there. I’m usually doing one-off things, so if it takes a little longer, it doesn’t make that much difference in the grand scheme of things so I’ll usually run slower than the calc says. I’m sure experienced machinists have much better strategies than that, but it works for me.

Nomad 883 http://carbide3d.com/specs/

A file is more or less arbitrary.

I’m wondering how to determine that the speed & feed rate I use is bad. I. e. most of the manuals suggest some combinations of those as a starting point, but how can you tell, for example, whether machine is still doing good if I cut at a rate that is too high? Or how can I see if the feed rate is too low?

So far I set the RPM to 10,000 which was suggested in one of the acrylic cutting tips and then I tried different feed rates in range 25 - 80 mm/min. I’m not sure how noisy a Nomad should be. But it sounded scary at some speeds. At some speeds I’ve seen material noodles sticking to the to the tool. I’m was not sure whether that was because it was moving too fast or too slow.

When you go too slow, you melt the material to the cutter.

If you go too fast you will get a jagged wall finish.

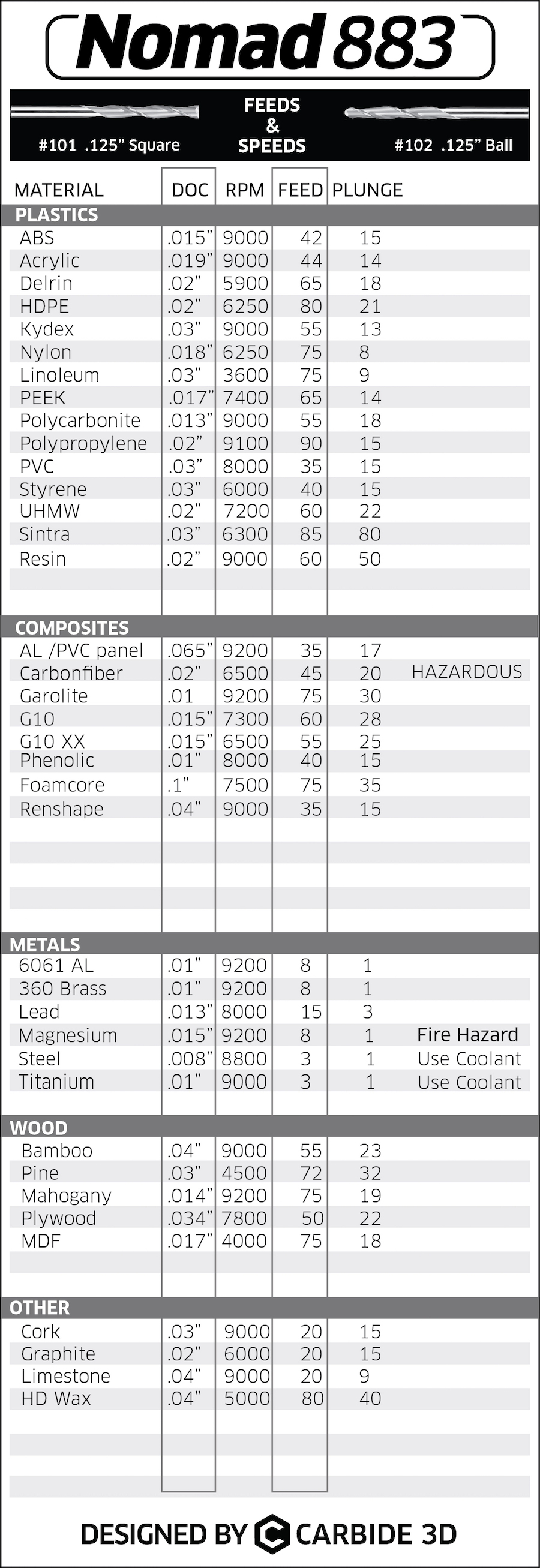

For best part finish in Acrylic start here:

.125" 2 flute (#101) endmill

9000 RPM

.019" DOC

44 IPM feed

14 IPM plunge

If you take a few cuts at a few different speeds, it becomes pretty obvious what’s “better” or not. If the machine is “screaming” and you’re cutting aluminum it may not be a problem, but the same noise when cutting wood would indicate you’re being probably too aggressive. A good calculator helps a lot (G-wizard works well for me) Slower feed isn’t necessarily better…took me a while to learn that one… Took me a while to understand that there really isn’t a perfect way to get onto that right feed/speed/DOC on the first try. In general, my nomad is quiet enough that i can hold a conversation next to it without raising my voice. Not when cutting metals though.

Suggested test cut technique: http://www.shapeoko.com/wiki/index.php/Materials#Testing_Cuts.2FMaterials

http://www.precisebits.com/tutorials/calibrating_feeds_n_speeds.htm

Great article, thank you!

I have doubled the feedrates without any problems. They suggest to start with the following:

(assuming 0.125" 2 flute endmill):

3% chip load per flute

0.125" DOC

which gives

10,000 RPM

75 IPM feed

and then increase the feedrate by 10 IPM per iteration until the sweet spot is found.

I’ve started with 2% chip load and tried the following feed rates: 50, 54, 58, 100. Still looking for the sweet spot

Hmmm… Strange experience. I started to cut diamonds instead of the straight lines. It succeeded on 75 IPM but got stuck on 85 IPM. Then it succeeded on 69 IPM but got stuck on 63 IPM. I’m not sure how to interpret these results.

Also I have material winding up on the tool sometimes. Is it a bad symptom?

Material sticking to the bit usually indicates overheating due to insufficient feed rate or too fast spindle speed.

I’ve just realized that I did wrong calculations. I was actually running at 7.5 IPM and 8.5 IPM. Just 10 times slower…

Apparently the formulas there do not take Nomad’s power into account. I’ve tried the suggested speeds (10,000 RPM on 50 IPM) as well as (2,000 RPM on 10 IPM) and it just get’s stuck.

I was not able to find a proper formula to identify how much power is needed to cut the acrylic through.

Could it be that Nomad is just not powerful enough to cut it in a single pass?

BTW, some other articles suggest it is still way to far below the suggested speed of cutting. Apparently those values are for the industrial systems not for the home ones.