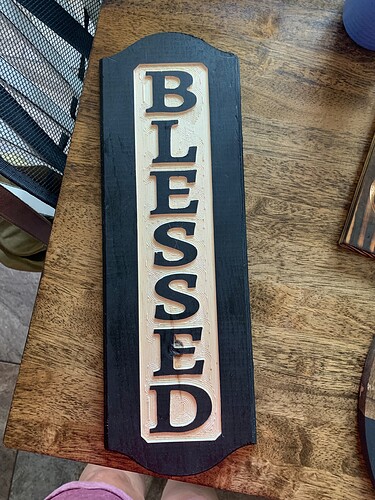

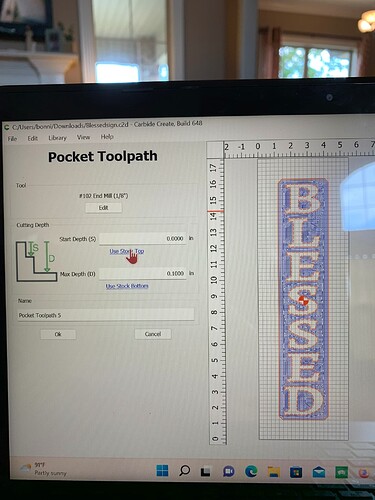

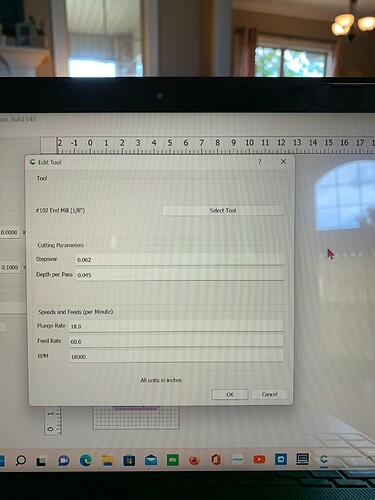

I’ve cut several pieces now . Made many boo boos along the way but I’m making some headway . Not sure how to set step over and plunge rate and all that stuff , just use presets within the cc program . I’ve noticed that I have a lot of shavings on from my wood and unsmooth cuts. I’m open to simple suggestions at this point .

What actual endmill did you use?

Do you have a link or can you upload a picture?

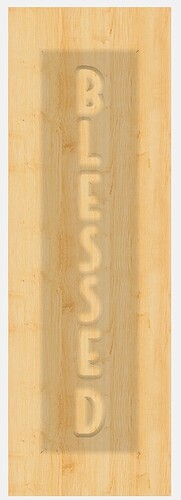

It looks to me like the router is not perfectly perpendicular to the stock, making the bit cut at a slight angle. I believe that can be fixed by tramming the router. I’m still fairly new to this myself, and haven’t experienced that myself to nearly this degree, but that’d be my guess. You can probably check by cutting a square pocket with a larger bit in a scrap and see if the edge follows along right at the edge of the bit.

I hope that makes sense.

Are you using a ball-nosed endmill?

That will naturally leave a scalloped bottom to a pocket.

Please use a square endmill such as a #201 or #251 which will cut a flat bottomed pocket.

An alternative to what Will Adams suggested would be an advanced vcarve. Use a #251 for the clearing (Down Cut) and a #302 60 degree Vee

Here is a simulation:

I agree with Will. Your step over looks correct to me. Almost looks like your using a ball end mill #101 instead of a flat end mill. Even though you have selected a #102 End Mill which is a flat end mill.

absolutely correct ….after I posted this concern …it dawned on me that I may have gotten my end mills mixed up . Gotta get better lighting lol thanks for all the information ![]() And help

And help

This topic was automatically closed after 30 days. New replies are no longer allowed.