So, super new to this but I’ve cut several test pieces so far with great success! Now, I’m stumped. I’m trying to cut a contour, ive Z0 the machine, my file is to the top of the work piece, I Z0 to the top and yet it stops about a 1/16 above the surface and runs the correct path, but never touches?

Very sorry to hear about this difficulty.

How are you setting the zero?

Please post the source .c2d file, generated G-Code, and step-by-step description of how you are securing your stock and setting zero relative to it.

Mouse.nc (12.4 KB)

I am using two hold down claps in a slotted waste board I attached to the bed. I am zero at the front left corner with the bit barely touching the wood.

Do you have the source .c2d file?

Sorry, I don’t know how to get it? Told you I was new!

You would have needed to have saved it.

If you didn’t, please try remaking things from the beginning and let us know how things work out.

I saved the .nc file, is that it? I appreciate your help, sorry I’m not up to speed to help you help me. When I saved the gcode it’s the .nc extenension.

If that is it, how do I view the source code?

Everything else I have created, saved and run worked fine, that’s why I don’t understand what’s happening now?

You export G-Code from Carbide Create — to save a file, do File | Save

Yes. To review:

- stock thickness in the file is set to 0.75 inches

- origin is set to top

If you’re zeroing on the top of the stock, but not able to cut deeply, that indicates it’s probably something mechanical. Please check:

- Pulley set screws: http://docs.carbide3d.com/shapeoko-faq/shapeoko-3-how-to-check-the-pulley-set-screws/ — be sure to check all axes/pulleys including Z.

- V wheels / eccentric nuts: http://docs.carbide3d.com/support/tensioning-eccentrics

- Belt tension — the Z-axis should be guitar string tight (but careful not to bend the motor shaft): http://docs.carbide3d.com/assembly/shapeoko/xxl/step-5-belting/ on deep cuts it may help to remove one spring from the Z-axis temporarily, esp. if one hasn’t added a spoilboard on top of the wasteboard — it also helps to install the router as low as possible (installing the Makita adapter upside down will help). Some folks have found it helps to remove bolts which won’t stay tensioned (M4 Z-axis tension bolt, various V wheels with eccentric nuts), apply a thin bead of threadlock along the length of the threads, then reinstalling. See the video at: https://www.youtube.com/watch?v=_lIIb_PdziA Note that the X-axis motor is held in place on standoffs and if those bolts are loose this can cause belt tension issues.

It is also important to be sure that the collet is correctly tightened, the endmill fits correctly and doesn’t slip, and the router is mounted securely in the mount, and that the mount doesn’t shift.

Thanks, I don’t think it is a mechanical issue as I am able to run other pieces with no problem? Let me mess around with it some more today. I appreciate the help! Randy

I will go back and check all the things you advise though to be sure I am all set up right. Thanks again!

If I read the first message correctly, the problem is not cutting too shallow, it’s not cutting at all, I understand the tool is hovering in the air 1/16" above the top surface ? If this is true then it is not mechanical, but

- either a problem with the zeroing procedure somehow

- or (more likely I would think) an uneven piece of wood that happens to be 1/16th thinner (or bowed) at the position of the cut versus where you zeroed at (bottom left corner)

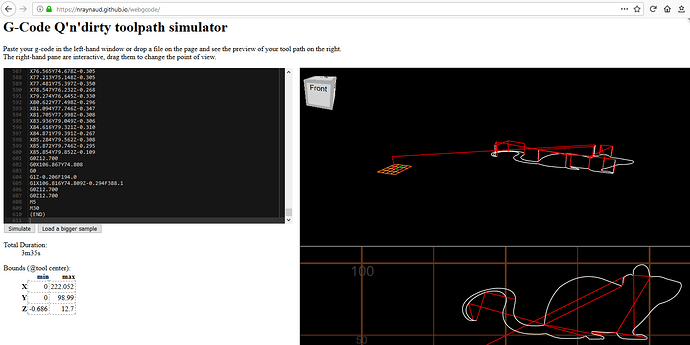

The reason I lean towards the latter is that the G-code file you attached shows a very, very flat toolpath:

The values in the lower left corner are in mm (apparently your G-code is configured for mm units, is that intended ?), and show that the G-code never goes below -0.686mm depth, that’s 0.03". This looks surprisingly shallow, is this what you wanted ? Also it does not seem to match the c2d file that you sent afterwards, which has an “end depth” of 6.35mm (1/4"), which looks much more typical/intended. Also, this c2d file in configured in inches, while the G-code is in mm ?

I wonder if maybe at some point you had CC configured to mm units by mistake, but typed in values in inches and generated the G-code and ran that. Can you re-generate the gcode file from the new c2d file and upload it for a check ? Does this re-generated G-code still give the same hovering problem ?

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.