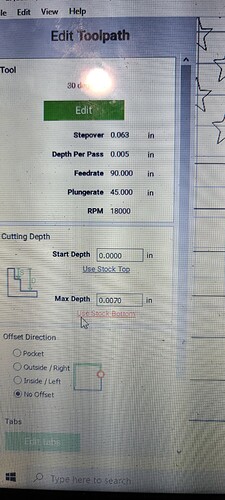

I am cutting a logo and ozone side it’s cutting uneven. Made sure my machine was square, belts have good tension. Some of its not very noticeable until the lettering on the right side. Any ideas would help.

Hi @Solanoo12000,

Shallow v-carving over a large area is tricky, as it will bring out any small local variations in a) the wasteboard surface and b) the stock material thickness.

The absolute must-do to get a fighting chance is to surface your wasteboard, AND make sure it doesn’t sag anywhere.

The second trick, whenever it is acceptable, is to first run a surfacing pass on the top stock surface itself, before running the cut. You may think your stock is flat, it usually isn’t (not to the level required for vcarving). Shaving off say 0.5mm off the top of the stock will leave you with a starting surface that is completely flat AND aligns with the machine’s axes, and then you zero off that freshly cut surface and run your vcarve. It does wonders to get nice, even depth of cut.

Finally, also make sure your workholding technique is not inducing any bending of the stock.

This topic was automatically closed after 30 days. New replies are no longer allowed.