I have a question on cutting fine details like a laser cutter would. I have this file that I got off esty for another project and I thought it would be cool to try this on a CNC machine. Its met for a laser engraver but I am wondering what tool would be best on a Shakepoko 5? I was thinking even a 1/16" bit would be too big and it would lose some of the details and 1/32" bit would take way too long. If you all were to cut this out on a CNC what would work best?

Have you tried an Advanced V carving with an acute V endmill? (30 degree for example)

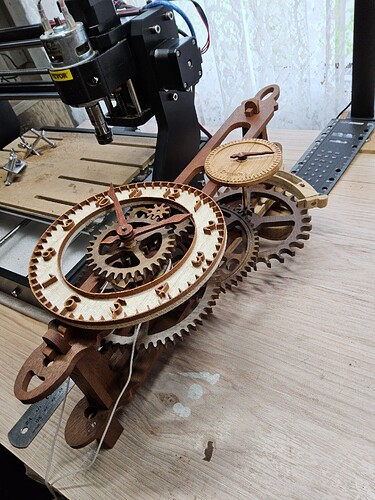

Yep, it is certainly possible. I have been playing around building a wooden geared clock from Brian Law and have altered a few of his plans just because I could. The clock is my very first attempt at making anything on a CNC and at my age (80yo) it’s been a bit of a learning curve.

The plan had the numerals carved onto the material and I thought it looked a bit plain.I laminated pawlonia and rosewood and surfaced it to a total of 6mm thick. That was the easy bit. Everything else was then pocketed with a 1.4mm bit. It took hours as I knew that the slightest bit of chipping or tearout would wreck my crazy idea. It turned out OK but I can’t sand it. It’s so fragile. Anyway,some food for thought.Cheers,Ben.

If you want the speed of a 1/16", but the detail of a 1/32", then you can either do Rest Machining (CC Pro), or

- Pocket with the 1/16", and then

- Contour with the 1/32"

In general, if you Pocket with one bit, then Contour with another smaller bit, you get the same result as clearing the entire area with the smaller bit if the smaller bit is at least 1/2 the size of the bigger bit. It’s more time that true Rest Machining, but it’s easy to program and available in CC free version.

You can also ‘stack’ the Contour bits, going down in size by up to 50% each time. For example

- Pocket with 1/4" bit.

- Contour with 1/8" bit

- Contour with 1/16" bit

gives the same results as pocketing everything with the 1/16" bit.

that is very nice looking

Greetings Will,

I was thinking of that and I have even a v 30 degree. I only tried to set this up with a contour and the time was like 200 minutes on 1/8" plywood LOL…so I was scratching my head a little bit trying to come up with something. I will try the adv V carve with a v.30 endmil and see what I come up with.

I am trying out the free version of the software now and I will be buying the Pro. that Rest Machining is absolutely killer!

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.