Phew, I leave on a short trip and come back to a lot of heated discussion here. I’ll answer your initial question to me first:

Thinking in chip per tooth provides a more holistic approach to milling materials. It combines both rotation speed, and flute count. This makes translation to other materials and machines much easier since you don’t need to ask for 3 variables as it already accounts for that. When someone tells you they cut maple at 0.05 mm/tooth, it contains more information than that they ran at 500 mm/min and yet takes approximately the same amount of characters to write out. This does still not tell the whole story (ADOC, RDOC, endmill diameter, etc.) but it’s a step in the right direction.

As for all the other conversation, I’ve done tribological (two materials rubbing against each other) calculations at work more for static considerations but similar concepts at at work here. Let’s consider the thermal energy balance:

(My primary source of non-experiential information is an excellent paper by Abukhshim, Mativenga, and Sheikh on “Heat generation and temperature prediction in metal cutting: A review and implications for high speed machining”)

Created sources of energy

Friction from the endmill rubbing the material (kinetic energy into heat energy)

Shearing heat from the endmills shearing through the material (kinetic energy into heat energy)

Since those are the two sources of heat energy in milling, let’s talk about what happens to it. There are 3 possible options here:

- It goes into the endmill

- It goes into the chips

- It goes into the substrate

Let’s talk about each of these.

1 - It goes into the endmill

This is a significant portion, although smaller than what people believe. In metals, roughly 10-30% of heat generated from cutting transfers into the tool. Given the lower thermal conductivity of plastics (by around 2 orders of magnitude [steel = 16 W/mk & PMMA = 0.25 W/mK]), that number is easily less than 10%. This means that most of the heat does not make it into the endmill but instead is transferred elsewhere.

2 - It goes into the chips

A common belief, and although real, is not the largest component. Let’s get into a breakdown of how cutting happens.

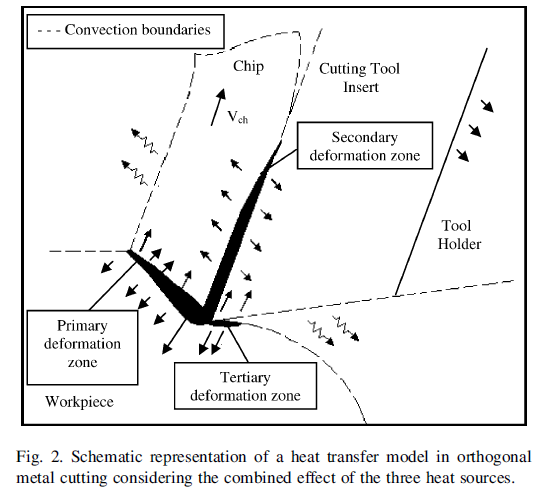

Shown below is a diagram of a tool cutting material. There are primary, secondary, and tertiary heat generation zones. In our common vernacular, we think of the primary zone as the shearing/cutting zone, the secondary zone as the friction/rubbing zone, and the tertiary is rarely mentioned in hobby machining at all. Heat generation into a chip happens in the primary and secondary deformation zones. The secondary deformation zone accounts for roughly 20-35% of the heat generation that the primary zone does, and given what we mentioned in section 1, most of that heat goes into the chip. Now, this is a substantial amount of heat that a small chip has to hold and not melt onto the endmill so the heat transferred into the chip must be less than what it will take to get the plastic to its glass transistion temperature (where it becomes very soft). If you are getting your flutes full of melted plastic, you need to speed up to increase the heat capacity of your chips to resist melting.

3 - It goes into the substrate

This is the last place the heat can go and accounts for the majority of heat generation in plastics especially. The heat generation happens in the primary and tertiary deformation zones, and given how plastics have much larger plastic deformation zones than metals, the shear-heating within the material is large since not only is the area by the chip being heated but material a few millimeters in is being heated as well due to thousands of deformations per second moving the polymers around. The heat generation here is at least 50% of the total heat generation and most certainly higher given the low material removal rates we run at and plastic material being cut.

The big importance to all this is that the amount of heat generated and put into the substrate (to contribute to heating and potential melting) is dependent on the material removal rate. The more material is removed and heat pulled away by chip removal rather than substrate heating, the less likely you will encounter a situation where your substrate begins to melt. This makes us hobby machinists need to push our comfort zones and actually take larger chiploads in plastics to avoid problematic situations.

Source: “Experimental study of the temperature field generated during orthogonal machining of an aluminium alloy.”

P.S. I didn’t touch on chip removal, friction affects from coatings, and more here. Please, look up published articles on these things. Nothing we are discussing here is new within the machining community and there is a lot of good science behind it all.