Hello everyone, so for the last two days I’ve tried figuring this out but I’m at a loss. I know this topic was previously mentioned but was closed and I must have not understand the answer that was given as I attempted the suggested resolution but fell flat. Please be kind in your response, LOL. I’m attempting to complete a simple 3D carve and I keep exceeding the wood allowance / cutting depth. Photo’s attached. Any suggestion on where the extra material / movements are coming from. Much appreciated for your incite and I look forward to your help.

This is a function of how the origin is set up in the file:

https://carbide3d.com/hub/courses/create/job-setup/

(Vectric has some equivalent set of features)

and how the zero is set relative to the stock:

https://carbide3d.com/hub/courses/running-shapeoko/movements-zeroing/

Our ability to assist with 3rd party software is quite limited — try making a quite simple pair of files, one in Carbide Create, the other in Vectric? If the Carbide Create file has this problem we can assist with that, if not, export the G-code and compare the twain?

We do have a blog post about this feature from when it first came out:

Great, thank you for the help. I will try your suggestion.

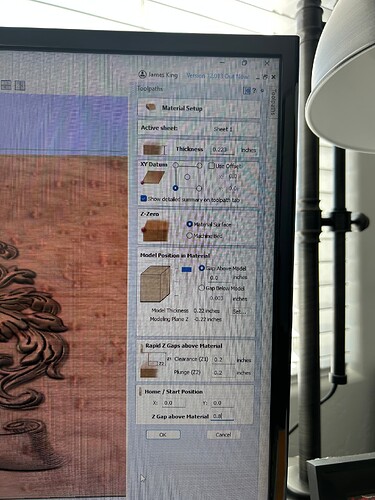

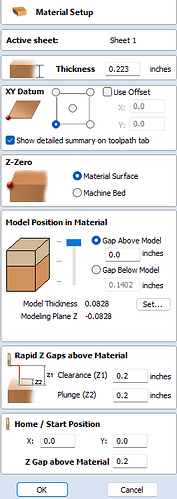

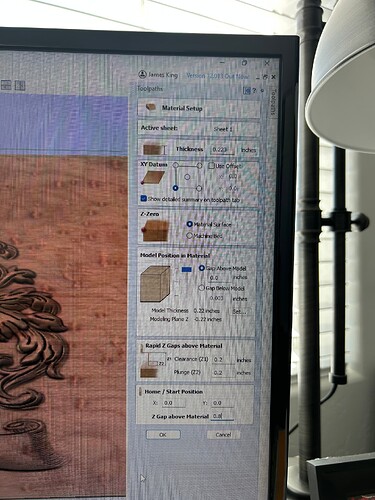

Is your material thickness really .223? Because your model leaves only .003 remaining. That seems pretty dang thin. ![]() Use thicker stock and change your stock thickness to whatever that is.

Use thicker stock and change your stock thickness to whatever that is.

Yes its’ really .223. There is a method to my madness as this thickness would allow me to complete numerous projects that I have in mind at a cheaper cost point.

OK. But your model thickness is .22. So the software says that’s too tight. Which it is.

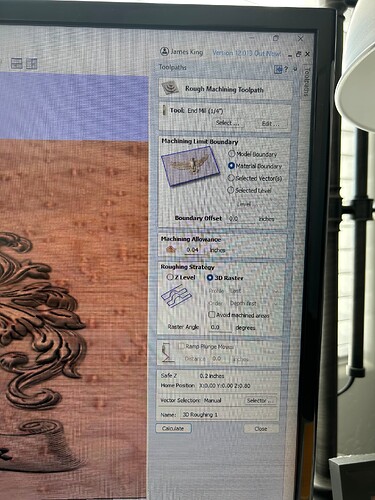

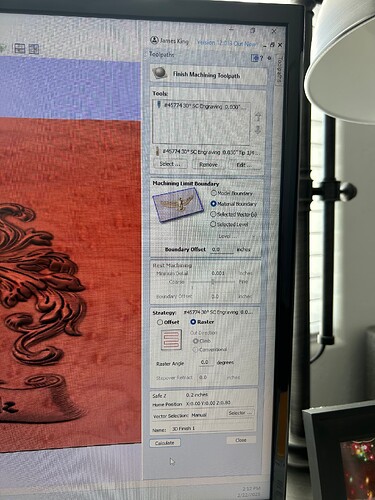

Software hasn’t said it was to tight, the wood is .223 thick, the model thickness is .0828 which leaves .1402 below the model. Essentially plenty of material. The problem is with the Z reference as carbide motion keeps taking the machine bed Z instead of the top of the material as I specified in Vectric Aspire. Reason why I know as I switched Vectric Aspire to machine from the bed instead of the top of the material and all is good. Not what I want but at least I’m getting some answers. I have re-zeroed everything but still checking before testing.

How decide where to zero the Z on the machine not CM.

Just make sure where you do it at the machine matches where you have it set in the design/CAM software. There is no magic connection between the two.

If you set to machine bed and use the BitZero to do XYZ on a corner it’s setting Z to material top. So, after setting the corners you need to reset Z at the bed. I do that a lot and really wish there was an XY measurement in CM. The only options are X and Y and Z individually or XYZ together. I find doing them together and then redoing Z individually easier than all individually but that does mean an extra trip to the bitsetter.

Hi Cullen, thanks for attempting to help. I started from scratch adding more detail to the model which changed my original specs. Before loading the cut files, I zeroed XYZ together (off the top of the wood). Tripled check XYZ and seems to be spot on but when I add the file it adds to the height of the material. Just cant figure out why CM is taking measurement off the bed (assuming at this point) when I specified in Aspire to take off the top of the wood.

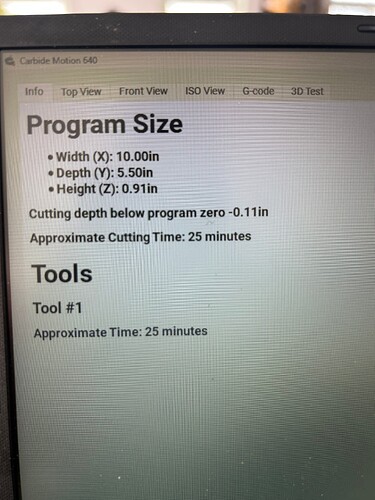

Currently the roughing Z height in Aspire is set to.223 but when I import to CM it goes to 0.28.

Finishing height in Aspire is set to .223 but when I import to CM it goes to .30.

Ugh, I have spent so much time on this it’s driving me nuts!!! Shouldn’t be this hard!

CM only takes the measurement off the bed if you tell it to.

How are you doing your zero process? Are you using a steel pin or a bit? Are you using the BitZero V1 or V2? Do you have CM configured to use the BitZero you have? They are different thicknesses and that can affect things, but the action is completely different as well so if it wasn’t configured for the correct one I don’t think anything would work right.

Are you using the bitsetter? Does it make a trip to the bitsetter after you set zero? If you are using a pin to set zero do you wait until CM prompts you to load a new tool after starting your program and does it then make the trip to the bitsetter again?

Lots of questions I know, but the answers will help the community hone in the issue and come up with an answer.

Oh, and one more thing, do you have CM configured for the right Z type? Do you have the Z Plus or the HDZ, CM needs to be set for correct one as they have different number of steps per inch. If you have the 5 then that is HDZ only and CM detects the correct one.

Hi Cullen,

That’s what I originally thought but who knows at this point (referring to taking measurement). Since I started this adventure, I have since adapted a new method of zeroing. I used to initialize the system, input the cut file, then start the zeroing process. I now initialize the system and then zero the XYZ off my previously set up wood then load the file. Regardless, same results.

To answer your questions:

- I’m utilizing my roughing bit to zero.

- My current zeroing tool is BitZero V2.

- I reinstalled CM after having issues, so I reconfigured the entire system using my specific specs. Shapeoko Pro XXL, Z Plus, enabled BitZero.

- Yes, I have a bit setter built into the system.

- Yes, it make a trip after zeroing. I then quick prompt the CNC to go to the XY point as well as check the Z for the correct height. This is all done before I load the cut file.

Thank again for the help, I will start over tomorrow morning, hopefully I will figure out the problem so I can start cutting again next weekend.

James

You may consider using a probing pin for the zero operations. If your BirZero didn’t come with one you could pickup a 1/4” steel pin from Amazon. That would eliminate issues variance with the flutes.

But remember, if your program is set to use machine bed you need to zero Z on the bed after doing the XYZ routine. You can use the BitZero for that, but I find it easier to use the paper method at that point.

Currently not experiencing variations when measuring tools, but may still pick up a rod for when I use a surfacing bit. I’m zeroing from the top of the material; I don’t think I have ever zeroed off the machine bed. I did the paper method yesterday to see how accurate the zero was and it’s spot on. I have a service ticket in with Carbide so hopefully they can help me figure out the issue. I will keep you posted. If any one has ideas I’m willing to listen as I hate to waste a day until I talk to support. Thanks everyone.