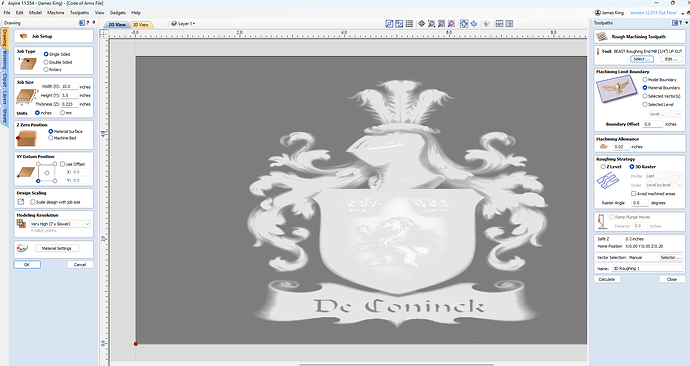

OMG, I’m having the same issue!!! I’m utilizing Vectric Aspire to create and then import the file to Carbide Motion and I’m having my stock thickness increased. It has to be a bug in both programs. I currently have a support ticked in with Carbide to help figure out the problem.

No, what is more likely is a miscalibration in Carbide Motion.

Which machine do you have?

Which Z-axis does it have? Which did you configure for?

If you jog the machine to the surface of the MDF, set the zero there, then jog up 1 inch, how much does the machine move?

No way a miscalibration, as the zero is true on the machine but using Carbide motion when importing my file it adds height to material. It has nothing to do with the actual machine.

Post a G-code file which doesn’t cut correctly, and a photo showing how the cut turned out, as well as a photo showing the machine at the origin or a specified offset from that position, and screen grabs showing Position/Machine Position (click on them to toggle).

Haven’t been able to cut the file as it goes below the material into my spoil board; found that out after trying to cut even after the warning. Carbide techs are helping me search for the issue, first response from them shows I have everything set up correctly, but they want additional information. Waiting to hear back after I provide.

You probably already checked this but you can configure the zero to be either top of stock or top of spoil board (bottom of stock). Having these set differently in the design software and motion can put the cut either above or below the stock

John

I have it set to the top of the stock in Vectric Aspire, but I don’t see where I would set the top of the stock in Carbide Motion as I looked for it. Is their such a setting?

James

This would depend on where you set zero relative to the stock as described in:

https://carbide3d.com/hub/courses/running-shapeoko/movements-zeroing/

I’m at work so I can’t look at my Vcarve Desktop, but looking at the Vectric tutorials reminded me that there are TWO places in the vectric software to indicate top or bottom. There is in the initial job setup (on left hand side of the screen), and in the toolpaths page(s)(right hand side) when you set up the toolpath. Check both places. (I’m not sure the behavior if they conflict but might be a clue)

John

The only other thing I can think of (and I am not an expert, but have used Vcarve Desktop) is what postprocessor are you using? Could there be something in that configuration? You are working with support, and I saw your question over on the Vectric forum. So you are accessing the experts.

Just a random thought- what happens if you set the zero an inch or two above the workpiece (or high enough to run without hitting the bed? My random thought is the cut just shifted down, or is it inverted? Not sure if that would tell you where the problem is but would indicate a reference point or a scaling issue (sign change on something)

John

Yea we checked the postprocessor and I’m using the correct one. So after a few days back and forth with support, we found that my Shapeoko is set up correctly and I need to use Carbide Create for a couple simple carves to see if there is any thing weird that happens. Not thrilled about the suggestion but what can I do since they have no clue.

I am also having issues with cut depth using vectric, at the moment it seems to be fixed and doing a reinstall of carbide ( cutter program ) and for now that seems to have helped. I have some pretty serious cuts just missing the aluminum part of the bed. When it was supposed to leave an onion skin.

Not sure honestly how to troubleshoot, it seems to get worse the longer I go in between reinstalls it seems to slowly drift lower and lower.

Our recommendation for troubleshooting software issues in 3rd party software is to make two simple, as equivalent-as-is-possible files in Carbide Create and the 3rd party software — then, if the Carbide Create file has this difficulty, we can look into it, if not, then G-code can be exported from each and compared to determine the difficulty.

Things I’d suggest looking into:

- feeds and speeds

- how secure the tool is

- tooling engagement

It seems to be more of a missing steps as it is doing the cut, resets with a tool change and then ever so slowly starts getting deeper and deeper. I’ve checked all of the obvious things and to make it all the more fun it’s more random than consistent.

If I do a reinstall before a big project it’s holding longer than just a zero all.

That sounds more like the bit slipping out of the collet. Next time after loading the bit draw a sharpie line around it at the edge of the collet and then pause occasionally during the job to see if that line is getting lower.

I did check that and it wouldn’t tighten, I do like the sharpie suggestion.

it’s happening after a few runs of different files with the same ¼ endmill and several bit zero calibrations. Yet if I reinstall the software it goes away for a few days.

I will attempt a reinstall of Carbide Motion, see if that brings any luck.

FWIW, I only use Vectric. I haven’t upgraded Carbide motion since build 521 as it works fine, without any problems. I also don’t know whether there would be any benefits for me from a later build, or just problems!

Whether installing an earlier build to the one that you are using will help I don’t know, but it may be worth a try.