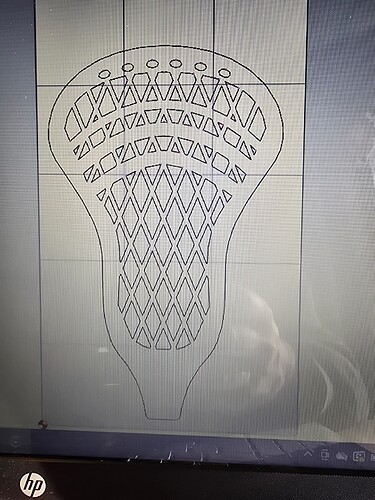

Currently working on a project and im test cutting some fine details with a 1.5 mm bit. Running at 45 ipm at 0.050 depth per pass. The issues im having is the peices keep tearing out. Would going to a smaller bit alleviate the issue? I’m thinking 1mm. Also what feed rates and depths are to be used? Currently I’m test cutting on mdf. The finished product will be on a cherry wood disk. Even at a cutting depth of 0.1 inches the details tear out. Its really got me stumped. Heres a picture of the cuttings

Small details like that tend to shear off easily in MDF. I’d try a different material and see if that works better for you.

Kevin made a video that kind of touches on this. https://www.youtube.com/watch?v=xA3jxCOM-Rs

But also, what may help is if you use a downcutting endmill for these cuts. You can buy ones 1/8" and smaller. Even cheap ebay endmills tend to work well for tests like these.

There’s not much holding MDF together. I’d try it in a fine-grained, closed pore hardwood. (cherry, hard maple, beech, walnut)

I am using a 2 flute down spiral bit. I’m going to finish surfacing the cookie then cut the design out on the back and see how that works.

I found the stepdown effects small sharp features. I would have small features that had tall “towers” during cutting. These “towers” would get snapped off prematurely when the cutter was working its way up a Pocket of Scallop operation.

Shellac helps if you can process in between Z height zones especially with MDF.

Reducing the Stepdown to allows certainly helps at the cost of time.