Any advice on how to get bits out of the collet? I can remove the locking nut just fine but the bits are stuck extremely tight. I broke a bit using pliers to try and get it out. I am brand new to this, but I’m sure there’s a better way. I’m using cheapo bits if that matters.

You shouldn’t need pliers, and shouldn’t use metal tools on endmills.

Do you have this trouble with the #201 endmill?

Use a pair of calipers to measure the endmills you have?

If you continue to have difficulties, please let us know at support@carbide3d.com and we’ll do our best to assist.

I don’t have a #201. I only bought the CCR from Carbide for my DIY CNC machine. I’m still stocking up on bits so maybe I’ll just buy some #201 and #102. Should the bits come out easily just using your hand? Good tip on not using metal on the endmills.

Yes, the endmills, when properly sized should fit easily, and be easily removed from the precision collets.

I can attest to the fact the precision collets aren’t always working with all bits.

I have c3d 1/8" ball end mills that don’t fit the collet, they are smaller and are hard to install. I need a third hand to hold the collet from dropping out up to the point where I use a wrench.

If you get something stuck take the end of a plastic screwdriver and gently tap the collet.

I’ve had a few bits get stuck. The instinct is to pull as hard as you can without cutting your fingers. I do 2 things. First I try pushing it back up into the router. This may cause it to let go. Secondly I give it a blast of compressed air.

When my Makita was new I got a carpenter’s pencil and used to mark the conical interface with some graphite. I haven’t done that for some time as I’ve been using the same collet, but if I switch to a new collet I’ll restart that practice again. It may be a good idea to do that until they mate into each other or develop some sort of natural “coating”.

The Makita and C3D router collets are cut to form a spring like clamp when the collet nut is tightened. The inside of the router shaft is tapered. As you tighten the collet nut it forces the collet up the inclined plane squeezing the collet closed gripping your bit.

When you loosen the collet nut the collet will expand forcing it back down the inclined plane and the grip on the bit is loosened.

Only gravity and the spring in the collet makes the bit release. If loosening the nut does not cause the collet to release the bit give some GENTLE taps on the collet nut and the vibration should cause the collet to relax and slide down releasing the bit. Do not beat on the collet nut and do not hit any exposed threads. Clean your collet nut and collet and inside the router shaft. Do not lube any of the components. They should be clean and dry.

The Makita/C3D collet nut is not attached to the collet. The Dewalt collet and nut are attached so when you loosen the Dewalt collet nut it drags the collet down the inclined shaft releasing the bit. This is why when loosening the Dewalt there is an initial slack tension on the nut and when you get the slack out the tension on the nut increases as you are pulling the collet down the inclined plane. Then the tension on the nut lessens a second time allowing you to use your fingers to remove the collet/collet nut.

I have a few broken bits, Yes I have a few too many.

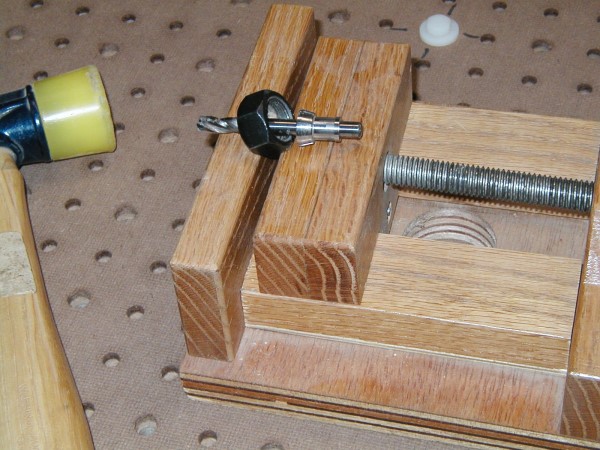

I take the collet to my vise open enough to support. (never clamp it) Take a broken bit of the same size and push or lightly tap the bit out.

Can you tell me more about what you’re suggesting? I’m not totally following.

I “color in” the conical section with some graphite from a carpenter’s pencil. I don’t mean so much that you have a dusting of graphite. Just “color in” on each of the conical faces.

My Makita collet benefited from this, until eventually I stopped and apparently was no longer needed. Like I said, I’m not sure if it’s a matter of the collet and shaft “wearing in”, or some natural “coating” developed. gdon_2003 seems to be against this, but I don’t think using pencil graphite is taboo among router users.

I believe this is what was being recommended. Remove the collet nut, collet and bit. Protect the nut and collet by placing them on wooden blocks. I have a wooden vise so that was already done.

Please use a non metallic hammer. You don’t want to damage the router bit shank.

Bill

This topic was automatically closed after 30 days. New replies are no longer allowed.