No, unfortunately. The machine is set to never sleep or dim display while on AC power.

Working Backwards:

Screen saver disabled

Sleep/hard drive sleep disabled on AC power

Yes

Yes

Error message: GRBL Error: Serial Port. Resource Error

We have a basic page on troubleshooting connection issues at: https://docs.carbide3d.com/software-faq/can-t-connect-to-machine-or-jog/ — if that doesn’t help, let us know at support@carbide3d.com and we’ll do our best to sort this out.

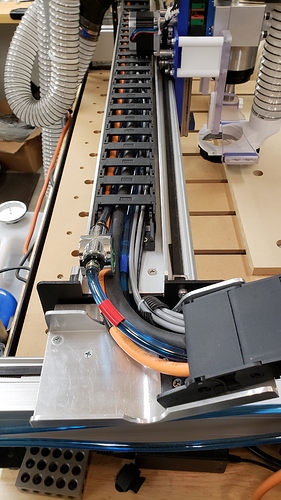

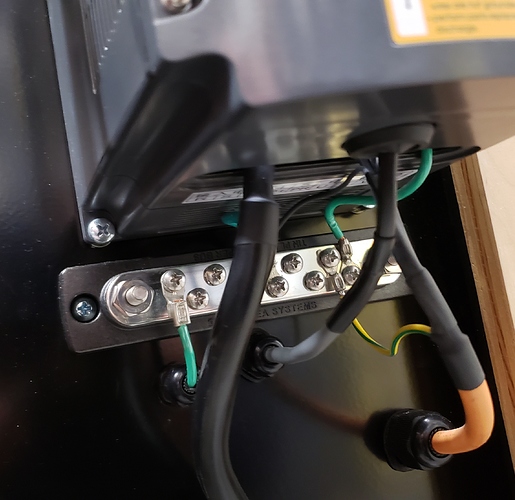

I’m not having any problems with my setup. I did the obvious things like keeping my computer from going to sleep. Or turning on a screen saver. My biggest worry was I’m using a VFD without shielding on the cable (orange cable) and running it through my drag chain with my stepper motor cables. I have upgraded my drag chain to a larger size and run my cooling to the stepper motor through it also. So I put my 2 cooling lines plus a piece of round foam insulation between my unshielded VFD cable and the rest of the cables. I also incorporated a marine grounding bus bar under my VFD and tied everything that could possibly be an issue into it. My spindle, controller card, VFD, 220v, and 110v grounds. That way everything I use is on an even playing field and hopefully no place for any stray voltages to build up. On the plus side I do not need to ground my spindle when using my setup probe.

I already contacted support, and they advised me to purchase (at a discount) a new controller board. That’s why I made this thread, to see if I could get it working without shelling out cash for a machine that should be supported by the company that built it.

For me it seemed to be the combination of both running the shop vac and its proximity to the probe return lead. I now refrain from using the shop vac during a job and also keep the prob lead connected to anything except a ground and haven’t missed a beat for what its worth.

Did you run your grounding bar to the local electrical ground of the plug or did you run an extra wire to isolate the ground back to the main electrical panel or some other grounding source?

Both my 220v and 110v grounds are attached to the bar since they are both bonded at the electrical panel I then ran the VFD, ShapeOko control board, and spindle ground to the grounding bar. That way everything is at the same potential.

I have had an interesting…frustrating couple days with disconnects. I have however linked it to my dust collection vacuum system. I have every bit of my system on a different circuit . What i find in my case was my vacuum hose was in contact with my power cord for my router supported with the same straps. I separated the vacuum hose and power cord and have not had 1 disconnect since. Prior to this I was getting a lot of ghosting of carbide motion while the program was running. Running now for 4 hrs straight with no issues.

Sounds like you may have found your issue. If it happens again you might look at your dust collection hose. Different material have different properties as far as static electric buildup is concerned. Mine is a very light weight clear plastic with a wire wound ribbing for support and the wire is in contact with the metal of the grounded dust collector. I’ve have not noticed any static buildup causing any attraction of anything to the hose. I’d have to look up the material the hose is made of but I purchased it on Amazon and it wasn’t too expensive

I had my first disconnect yesterday when I used the suckit dustboot for a long carve. I removed the dustboot and vacuumed by hand without any issues. I need to install a ground for the vacuum tube to let static electricity discharge.

I need to do this also, but I’m not sure how to exactly do this properly. When cutting anything I get a TON of dust sticking (due to static) to outside of my Suckit dust boot. Resulting in disconnects. Have tried both my shop vac and my HF dust collector and have same problem.

I have seen that people have installed a bare copper wire running the length of the vacuum tube then connected to a ground. As Gary, @HDRyder has shown above, he added a grounding bar to his table to ensure everything is grounded together.

I have to get all the parts and do the same, I currently sick at home so it will probably be a few days before I get everything. Until then, I unplugged the dust boot and manually suck the dust by hand. I have not had a disconnect since.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.