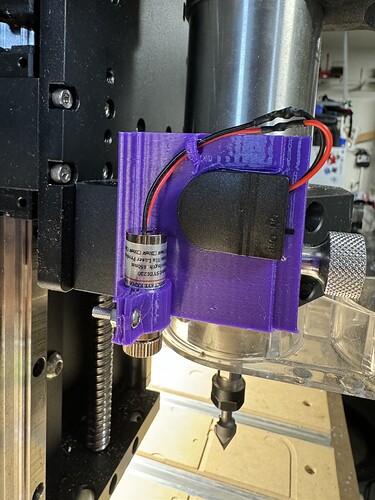

Took a laser mount someone made for the Phecda and just modified it to work with the cleat.

My offset is 3.523 x -0.440. Now to figure out how to make an action that enables or disables the offset.

I see some work was made here : CM Work offset? but I don’t see a final working method.