Thinking of getting an HDM however am just wondering how good of a surface roughness can be achieved with this machine.

I’m interested in the answer as well. Though I assume it’ll be hard to get and hard numbers.

I assume max Ra will depend largely on one’s specific setup (individual tooling, workholding, and tool pathing) and I imagine very few people are set up to measure Ra accurately.

Maybe folks can share photos of the finishes they’ve achieved straight off the machine if they can’t measure the Ra ![]()

I believe you’re going to have a hard time finding people running HDMs who have had the RA measured as that is usually aerospace/medical level metrology. Our HDM at work has done plenty of experimental medical, and even experimental nuclear reactor parts, but no one has been concerned with RA thus far. All of my projects have not had surface finish as a concern unless they wanted a matte finish and media blasted after machining and before anodizing. So my programing and pictures are not optimized for RA. It also depends heavily on the tooling (diameter, style of tooling, flute count, etc), workholding, the experience of the operator, and how long you want to take on finishing passes. I could make a program with several finish passes, with a tool change to a larger diameter endmill with 4 flutes and finishing geometry to optimize RA. Unfortunately, that has not been specified yet. I have gotten plenty of rainbows on the HDM V1’s I have ran, but haven’t had the opportunity to cut aluminum on my HDM V2 yet. It is substantially beefier than my V1 and the spindle has better bearings.

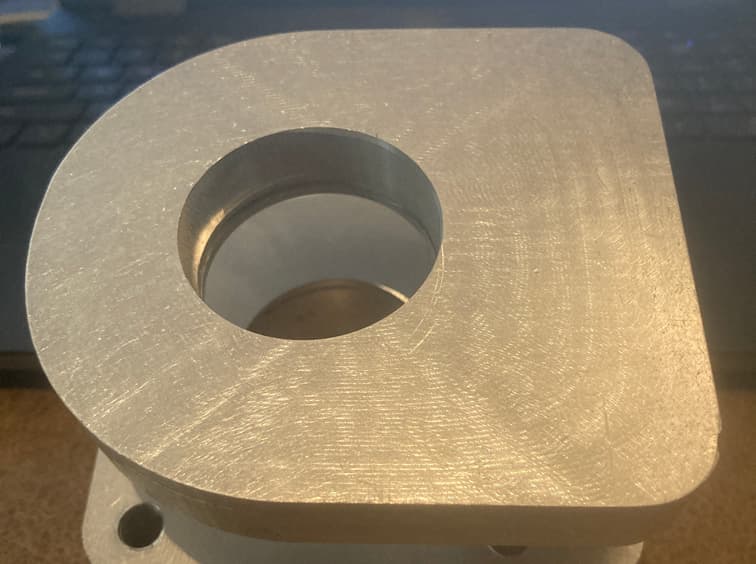

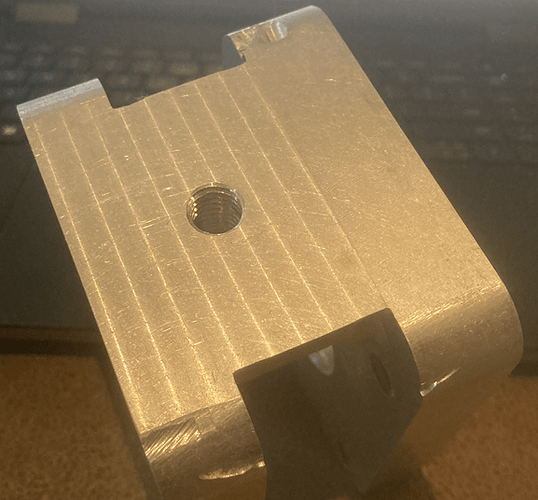

I’d be interested too. I gotta believe a well tuned, calibrated HDM can get better than the standard 3.2 µm finish. Here is a part I did on my HDM

These are the best pics I have. But my phone doesn’t like close-up pictures much, so they’re kinda crappy pics. This was done on a HDM V1 with some unknown usage, not the sharpest, 3/8" 2 flute endmill and programmed for speed, not finish. It’s also been kicking around the shop for a while, thus the scratches. Were I programming for surface finish I would have used a 3/8" rougher, then swapped to a new 1/2" 4-flute (with geometry for surface finish rather than higher MRR with multiple finish and spring passes, and done multiple finish and spring passes.

This topic was automatically closed after 30 days. New replies are no longer allowed.