Hi Neil - I will probably have more than one question! Hope I’m not hijacking this thread –

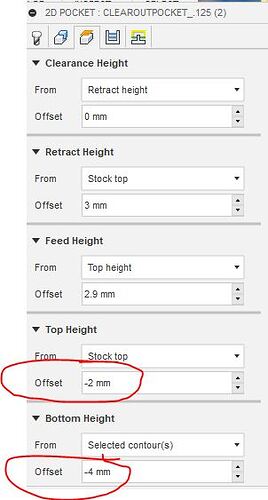

I’ve been studying the female-side toolpaths in your “dawg” example. I see most of what you are doing, but I’m puzzled by a couple of settings. The MainPocket mills -4 mm from the selected contour; that makes sense to me. But the ClearOutPocket Top Height setting of -2 mm puzzles me. What is that setting accomplishing? The toolpath still mills down to -4 mm from the selected contours, so…?

Also, I noticed that in the MainPocket you have radial stock-to-leave of 0.2 mm but in the ClearOutPocket you have radial stock-to-leave of 2.5 mm. Any significance for those two numbers, or for the difference between them?

Finally, you said in your writeup The pocket is set to have an overall depth of 5mm. But your flat bits are only milling to -4 mm, and only the last V-bit inlay toolpath goes down to -5 mm. Doesn’t that mean the flat spaces in the female side will only be at -4 mm, with a -5 mm v-groove from the v-bit around the periphery?

Thanks!