Hi,

I try to machine a “brick” from both sides.

What I did:

- Create the brick in fusion 360 as 3d and put it to the right size

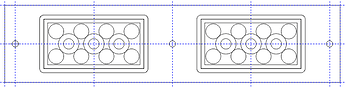

- Export top and bottom as DXF import it it in Corel Draw

- Align top and bottom, make 2 bricks side by side

- Define the size of the piece of wood I want to use and where to drill the holes for the clamping screws

- I export top and bottom as SVG

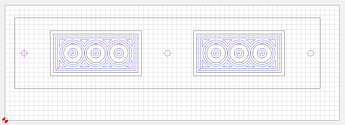

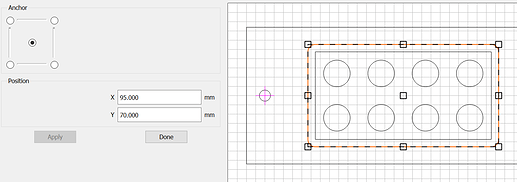

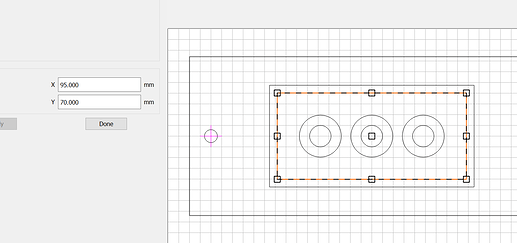

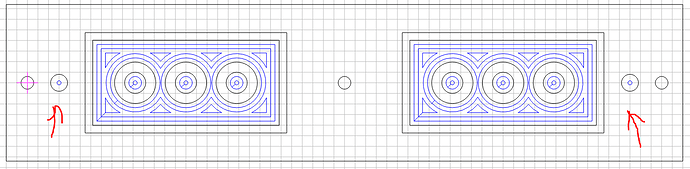

- in CC 5 I import one file and place one screw (see magenta cross) at the position where I have the first screw position in the wastboard. Next screws will come every 50mm on both axes. Now the bottom looks like this:

*Same for the top

- I checked all positions in CC for both sides, they are exact at the same position

- So top and bottom shall fit !

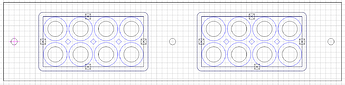

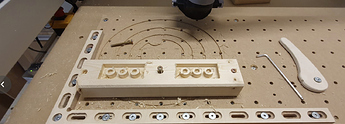

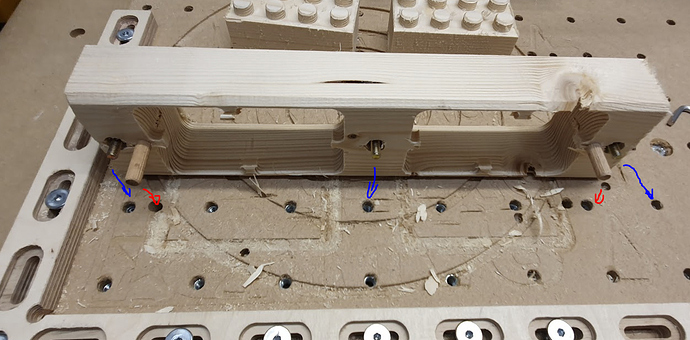

- Here the result from machining the bottom:

- next step I flipped the stock around the X axis:

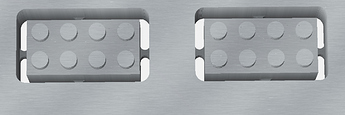

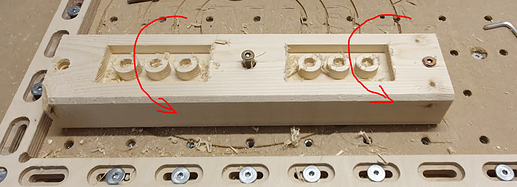

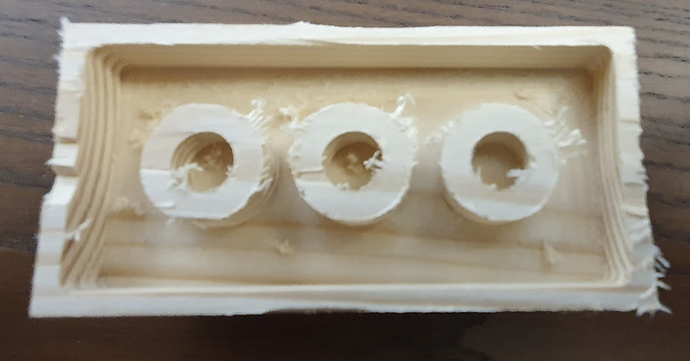

- and the top looks like this:

- looks not so bad but:

there is a difference in the thickness of the walls 4,5mm and 2mm - My idea: Maybe the position of the clamping screws is not 100% right (I drilled the holes by hand in the wasteboard)

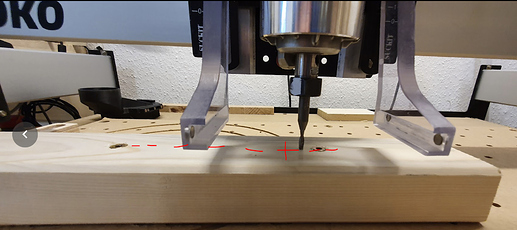

- So I draw a line in x direction over the complete stock, mark one position at the top of the stock, screwed it to the wastboard and put the machine to the cross (sorry I did not took a picture of this step, so here a fake picture which shows my idea.)

- with a V-bit I checked the position and found the biggest gap in x direction (which doesn’t matter) and only less than 1/2mm in y direction.

- So the zero position fits very good to the screw positions in the wasteboard.

- I compensate the small deviation by zeroing the machine again and did the same test.

- Now the V-Bit das direct over the cross on the stock. With good glasses and looking from all sides I am pretty sure that the deviation is below 0,5mm

- Now I got 4mm and 2,6mm so round about the 1/2mm I had adjusted but still 1,5mm difference.

- The wall shall be 3,6mm

- If I measure the overall size of one brick ist is 95,3mm (shall be 95,4mm) and 46,98mm (shall be 47,4mm)

So a very long text for a question

Does anyone have an idea concerning the 1,4mm difference in wall thickness.

Do I forget something.

While I write this long text there is one idea for the next brick, I will flip the stock next time over the Y axis and see what happens than.

Thank you

Peter