Quick question. I can’t 100% wrap my head around this, but does using climb milling on a downcut endmill have the same effects as it does on an upcut? I understand the advantages of climb milling vs conventional, but does reversing the spiral on a downcut change any advantages of climb milling? Obviously the spindle is still rotating in the same direction, so there’s that.

Interesting question…

Me, I would naively tend to say that since climb versus conventional is something that mostly affects cutter forces in the X/Y plane, while upcut versus downcut results in something mostly along the Z axis, the two are independent, but I’ll be quite interested in what more knowledgable folks others have to say! (@spargeltarzan maybe?)

That was my initial thought too, but as I was watching some high speed video on end mills, I got to thinking, isn’t the rotation of the cutting edge effectively reversed with a downcut? Maybe not? I don’t know.

@Julien is entirely correct: Upcut/downcut and climb/conventional are independent. The downcut endmill just has the spiral leaning “forward” instead of “backward”, which has no bearing on the mechanics of climb vs. conventional.

In terms of forces, the only difference between upcut and downcut is that the axial force changes sign: Normal (upcut) tools are pulled down (Fz < 0), downcut tools are pushed up into the collet (Fz > 0).

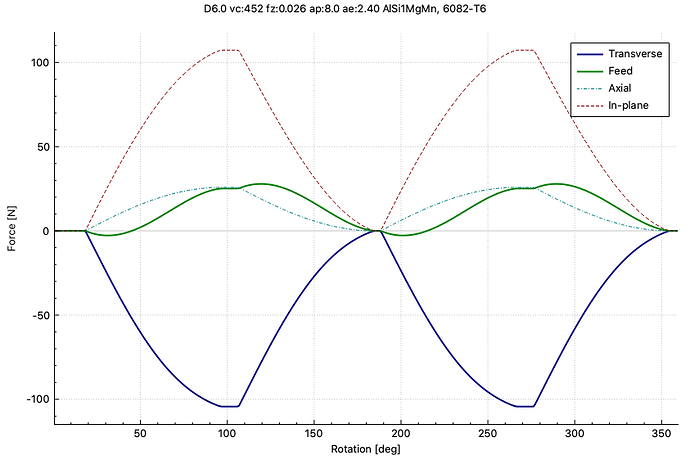

Forces downcut climb:

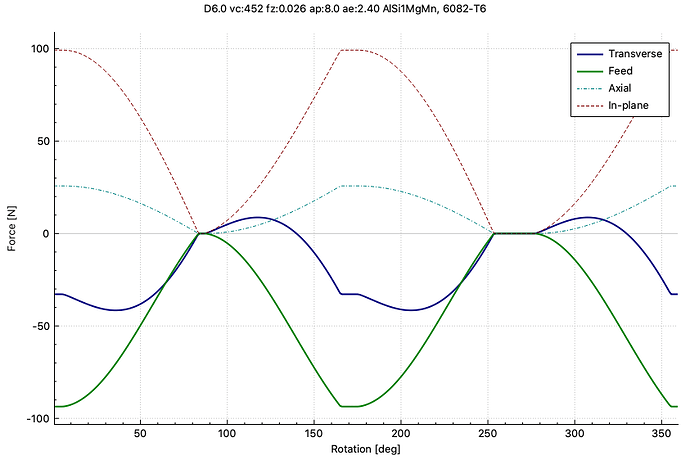

Forces downcut conventional:

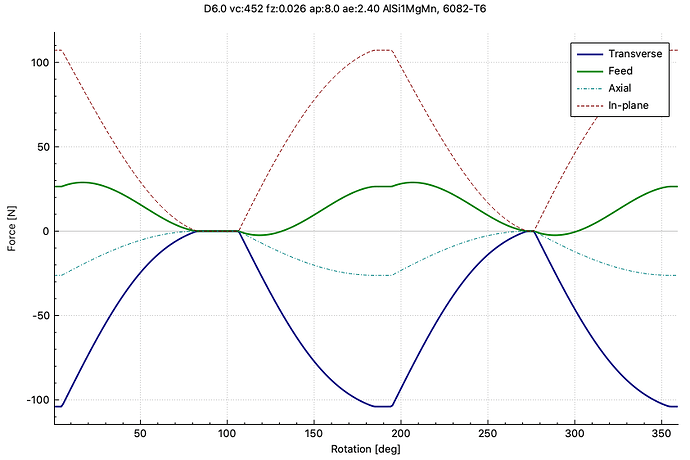

Forces upcut climb:

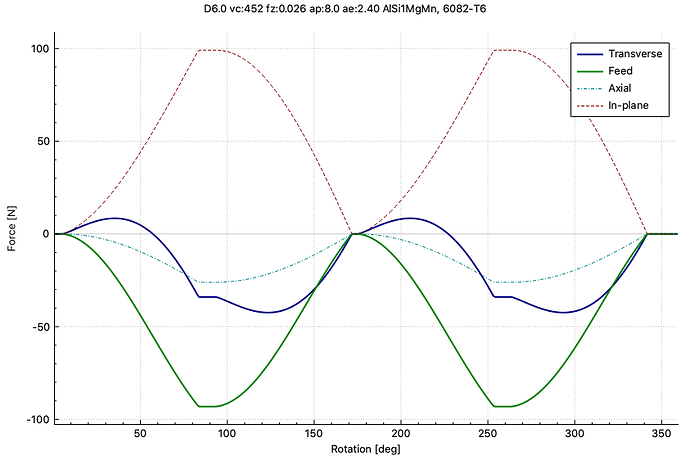

Forces upcut conventional:

Would you mind sharing your code? I’m impressed and curious how you modeled this.

(this is from @spargeltarzan’s millalyzer software, available here)

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.