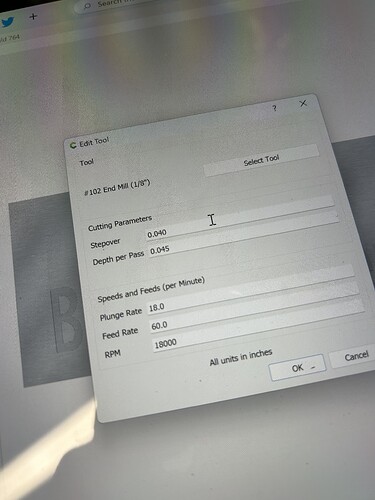

I have not experienced a dull end mill so far. But what could be causing the tear out in the middle of my “pocket” using a #102 1/8” end mill?

It is pine and using default softwood F and S.

Increase stepover?

Also, what is your Max Depth and Depth per Pass and how do they relate?

e.g., if Max Depth == 0.5" and Depth per Pass is 0.125" so that 4 full-depth passes are being taken, if one instead changes the Depth per Pass to 0.124", then 5 passes will be made, for at full-depth, then a 5th, essentially finishing pass removing only 0.004" of material.

I can see step over issues. If you reduce the stepover it will cut the bottom a little bit better.

The bit can be checked by what I call the finger nail method. Drag the bits cutting edge over your nail followed by a new bit. If the same or similar, sharp.

I reduced the step over but still seeing the issue. I have never had an issue like this using the defaults.

What are the default stopovers for a 102 softwood? Did I somehow get them goofed up?

Is the pine really wet ? It looks like it mushed the edges.

Could be. Got it from Menards.

But the main thing is the first pictures where it is missing the center of the pockets.

I found my moisture meter. It is a cheap one but it read 7% n

You did not say what version of CC you are using. They had a bug that would leave a little wall inbetween cuts and as @WillAdams suggested reduce step over. I think they fixed it in later versions.

A good sanity check is to modify the tool in the tool path and reduce step over. Then save and open the tool path back up in edit to see if indeed the step over was reduced. Some people have reported they change step over in the tool edit but it reverts to the default.

It is version 764. And CM version 636.

I will have a closer loom at the step over and see if it changes or not.

I wonder if I could fix by using a 1/4" #201 and a Contour with no offset to fix. I think that should work.

This topic was automatically closed after 30 days. New replies are no longer allowed.