I surface a lot of Hard Maple end-grain cutting boards as bread-and-butter work… Usually I throw 3 to 5 boards on the bed with no work-holding and after about 100 of these I’ve found that my best results were achieved with this 1" Whiteside Surfacing Bit using these Feeds and Speeds:

Roughing: .0625" DOC .45" Stepover, 18k RPM, 200 IPM, .0034 Feed Per Tooth, Climb Cutting Only

Finishing: .03125" DOC .25" Stepover, 18k RPM, 200 IPM, .0034 Feed Per Tooth, Climb Cutting Only

Slower and the bit will cause burning, conventional cutting and the bit will burn, faster than 200IPM and you’ll get excessive grain tear-out.

Now heres the head scratcher… after about 100 of these I was like well… maybe if i got a fresh/new bit I could push >200ipm and not have any tear out as the cutting teeth would more efficiently cut the wood fibers rather than “pull” on them (like a dull razor and your stubble).

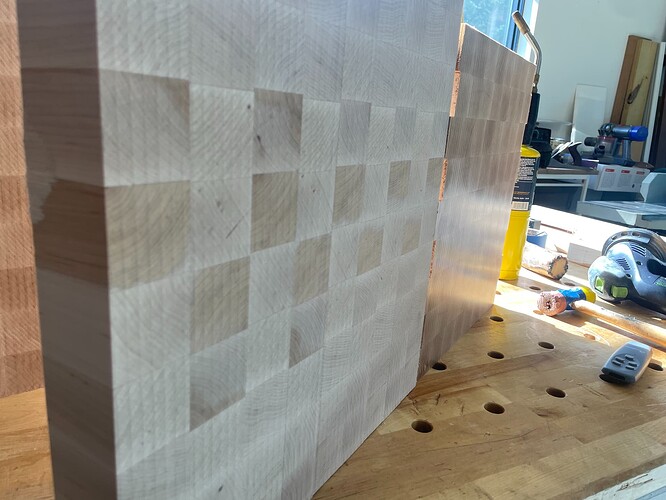

The results were the total opposite… the old dull bit using the same F&S produces a finish that is nearly semi-gloss and feels VERY pleasant to touch, its probably 400-600grit right off the machine. And the brand new bit feels like 80-120grit and has TONS of tear out. (before you say this because each board of maple is created different I also ran the dull bit on one side and the new bit on the other side and had the same result… aka it’s not the wood).

Theories?

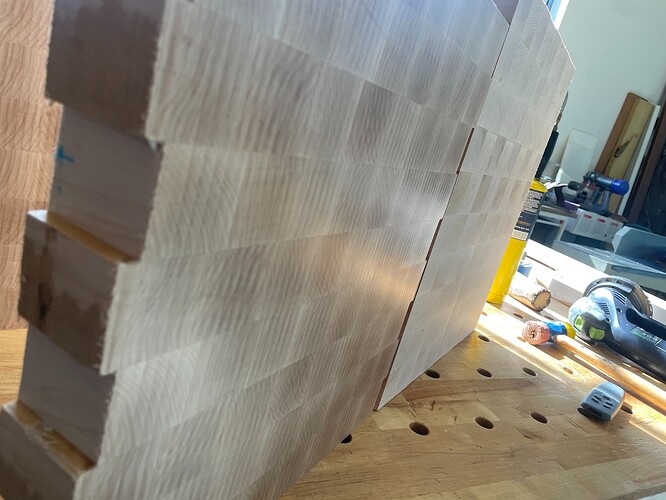

New Bit:

Old Bit:

Side By Side Old bit in Foreground:

Side by Side New bit in Foreground: