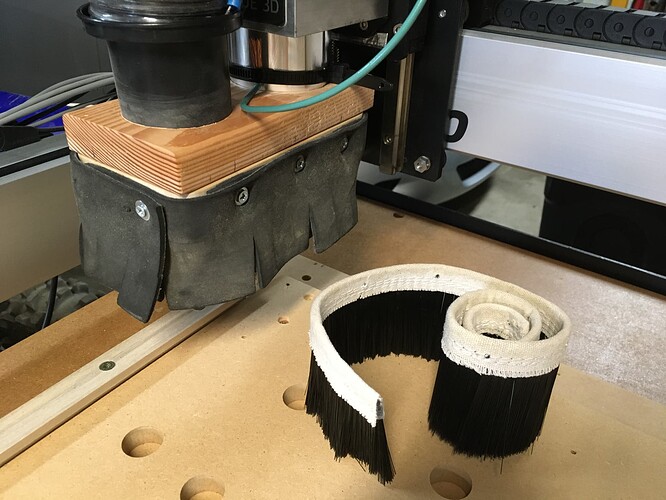

So I created a dust shoe for my Shapeoko some time ago. I used some material I got in the clearance section at Walmart for the “brush” part and it works pretty well. Recently I bought an actual brush strip on Amazon and attached it. That is when the problems began. I was getting ridges in pockets and star cutouts of different sizes. Thought it was the machine or maybe the bits - checked everything over and could find no problem. So I ran it without the dust boot and all the problems went away. So as it turns out, the bristles of the brush strip are strong enough to interfere with the Z axis movement even with the screw driven model. Just a word of caution.

Peace

Madison - MadPedalBoards.com

I bought a dust shoe for my Dewalt. The dust shoe had a foam brush and it detoriated quickly. I ordered a regular bristle brush from the same vendor. The bristles were about 3.5 inches long so I gave it a hair cut to about 2 inches and it worked great. The longer bristles dragged on the work too much. Very little dust escapes. Your brush looks a little long and may be getting caught on the edges of the work piece.

Yeah, the foam I am using will compress in the Z axis quite easily, whereas the brush would not and thus fights against the Z negative motion. I might try mounting it such that the brush is at an angle to the work so that the bristles are not being pushed straight down into the work surface. It did do a better job of containing the dust. We will see.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.