Does a dxf file differ from a svg file in carbide create when it comes to toolpath run time? I have been making “catch trays” out of 1" thick cherry, 9.5" wide by 10" tall. I do different logos and designs. I have made one of the fire dept maltese cross. It took 6 minutes to cut the shape out, 31 minutes to pocket out the interior shape and 1 hour 7 minutes to then cut the design of the maltese cross in the pocketed area. I got a request to change the words “Fire Dept” to “Richmond Fire”. I got somebody on a facebook group to make this for me, they sent it to me, I loaded it in and created a new file. The cut out and pocket time stayed exact same, but the design cut time went to 2 hours and 19 minutes. Feeds and speeds are identical. So really only one word changed in the file, everything else stayed the same. Any ideas?

There should not be any impact of importing either a DXF or SVG, because CC converts them to its internal vector format anyway, and then the toolpaths are computed based on the geometry.

BUT it is still possible that something was subtly different between the original svg and the dxf recreated/updated by someone else, I have seen reports here of doubled features (barely visible to the naked eye) and things like this.

If you can you post the two c2d files we should be able to tell what’s going on. CC is not always super accurate in its cutting time estimates, so loading the generated G-code files themselves in a G-code viewer could help figuring it if there is a real difference, or if this is just a bug in the time estimate in CC

There seems to be a bit of difference in how these are processed:

- SVGs are directly imported and converted into Curve objects

- DXFs seem to be geometrically analyzed and where possible polyline representations of circles and so forth are converted into Curve objects

If you could post the DXF we’d gladly look into this with you.

When I get home tonight I will post files. Thanks!

RICHMOND.dxf (351.4 KB)

Maltese cross catch tray.c2d (1.2 MB) Richmond fire catch tray.c2d (841.4 KB)

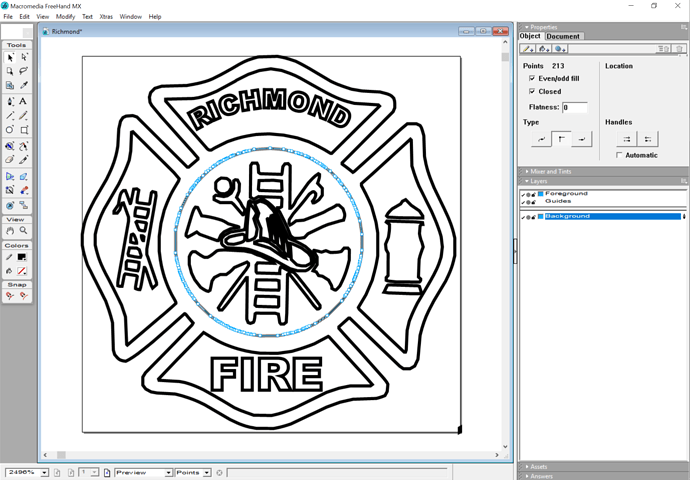

As noted, Carbide Create simplifies that quite a bit when importing the DXF version — the circle for example has 213 nodes in the original file:

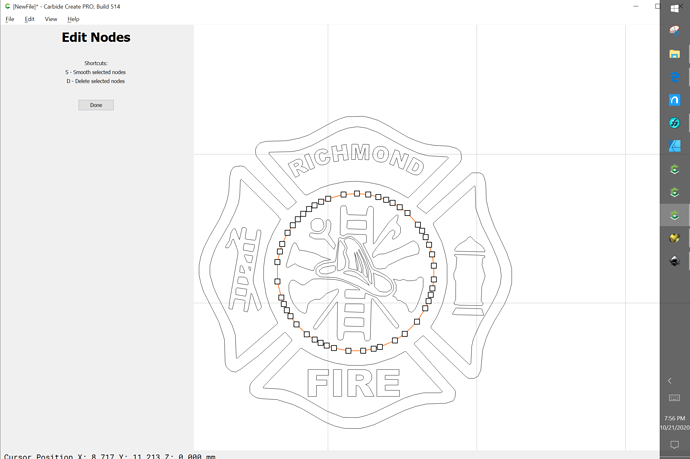

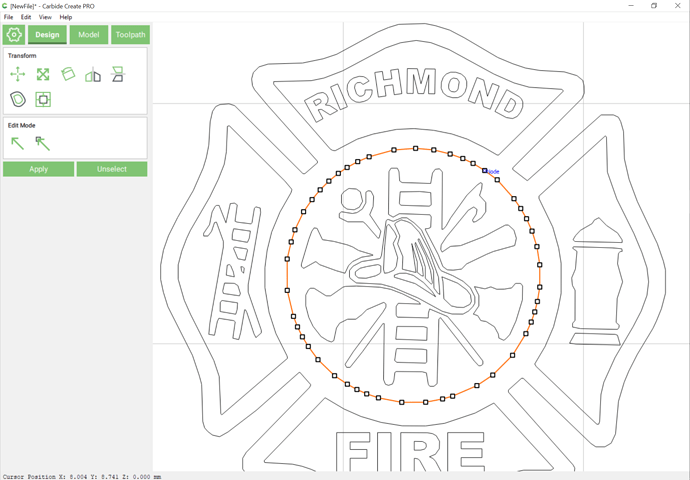

but markedly fewer in Carbide Create (v5):

while in CC4 it has a few more nodes than that:

(but not 213)

I’d suggest trying the CC5 beta to see if it has better performance:

So i have always had the fear of losing work when using the “beta” versions, after reading the warning that work can be lost. Is there a great risk of losing anything? Thanks and I will give this a try.

Work on things in parallel in both versions at the same time?

but you can’t take files from v5 back to v4 so be aware

how do you do that? When I download it doesn’t it take the place of the other version I have?

the v5 beta will install adjacent next to the old version, by design

(yes that’s very convenient)

You can export the geometry as an SVG and get pretty much everything but the toolpaths.

This topic was automatically closed after 30 days. New replies are no longer allowed.