Hello all, I bought this yesterday at Lowes (still in the box). While trying to figure out the difference between this one and the DXV12P-QTA (appears to be hose & accessories differ) I found the reviews for the DXV12P-QT on the DeWalt website. Has anyone had any fire hazard issues with this vacuum? I’m wondering if I should keep it or return it and go with something else for my 5 Pro which is going to be ordered soon. Thanks.

Most of these products have to go through UL testing. So if they were catching on fire hopefully they would not be allowed on the market.

The main issue with most vacuum hoses would be if they are static resistant. Static can take your Shapeoko off line so you want to prevent static.

Let us know what you turn up if those are some kind of fire hazard.

Good point. I’m not seeing anything about UL in the manual, or on the website. I’m also wondering if those folks didn’t maintain the filter/bag.

I will note that using a cyclone such as:

will help reduce the need to replace bags and filters.

I agree with @WillAdams about the cyclonic type cannisters. You get most of your dirt and debris trapped in the first state and your second stage (Dust Collector) gets very little dust and chips so the filter stays clean longer and maintains your air flow.

I have a dedicated Jet 1.5 HP 1100 CFM dust collector with an Onieda Super Dust Deputy making my one stage DC into a 2 stage one. I can tell when the onieda bucket is full because I start seeing saw dust in the Jet bag.

The onieda dust deputy is great for the 2.5" shop vac systems and there are other brands but they do basically the same thing. The dust comes in and spins around and the heavier particles slow down and fall into the bucket. So only very fine dust goes onto the actual shop vac/dust collector.

I use that vacuum almost every day (for more than a year) for hours long cuts without a single hitch.

I have a Dustopper cyclonic filter inline, too.

I also have a whole workshop air filtration system, that I’ve tested with a particulate meter.

This system just works.

I also use this same vacuum with an Onieda Dust Deputy fixed to the top of my old Stanley vacuums canister. Nearly a year old and going strong.

I too have used that one for almost a year. I have a cheap Harbor Freight cyclone and a 5 gallon bucket in line. No issues.

Will arrive Wednesday. Thanks!

Regarding the vacuum itself, I like that it’s quiet. I like there’s a HEPA filter for it. What I don’t like is there’s no HEPA bags for it that I can find. My louder Riged has both. I’m bummed about that. Anyone know of HEPA bags for the DeWakt? Thanks.

You may be able to find a way to adapt a secondary HEPA filter or bag to the outlet.

We have a Ridgid at work with a cyclone (that I sealed better), the HEPA filter, and a HEPA bag for when we cut composites. I do like that set-up. It is more quiet than past shop vacs, but definitely not the most quiet.

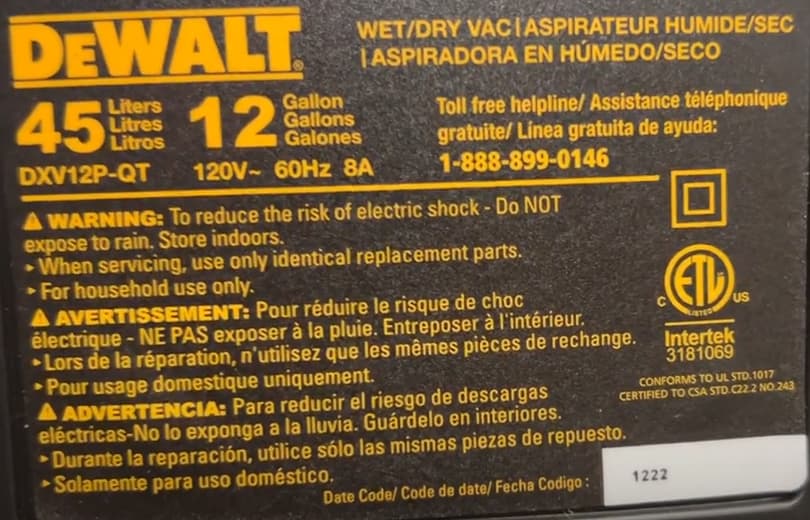

Got this from YouTube video. Conforms to UL STD. 1017. Not sure what that means.

Dewalt reviews pretty scary. Second-guessing getting same model.

I bought after market HEPA filters from Amazon that were a lot cheaper than the Dewalt branded ones.

Thanks, I didn’t see that. I asked AI about this. Here’s what I got

A product that meets the UL 1017 standard assures you of several safety aspects, particularly for vacuum cleaners, blower cleaners, and household floor finishing machines. Here are some key points:

- Electrical Safety: The product is designed to operate safely within specified electrical parameters, reducing the risk of electrical hazards1.

- Mechanical Safety: It ensures that the product’s mechanical components are safe to use, minimizing risks like overheating or mechanical failure1.

- Fire Safety: The standard includes requirements to prevent fire hazards, ensuring the product does not pose a fire risk during normal operation1.

- Durability and Reliability: Products are tested for durability and reliability, ensuring they can withstand regular use without compromising safety1.

Overall, a UL 1017 certification provides confidence that the product has been rigorously tested and meets high safety standards. If you have any specific concerns or need more details, feel free to ask!

Do you think “normal operation” is intermittent, e.g. < 10 minutes?

Very weird that all those bad reviews about fire hazards are from the cord. One would think that is a pretty easy thing to get right. I wonder if all those people have a habit of yanking the plug out of the wall from 3 feet away by the cord.

Also odd that the Dewalt responses on all those is to have customer support get in touch with the people but not offer a follow up message for the rest of potential buyers

Never underestimate an end users ability to do it wrong.

I’m guessing a CNC job can go hour(s)?

Yes I have had a few multi hour jobs and have heard others with 12+ hour jobs.

More likely on 3D stuff, very intricate designs and probably aluminum probably.

There is no doubt that HEPA is a good thing. However the HEPA traps fine particulates and to do that it has to restrict the flow. On smaller dust collection systems it is the flow that captures the sawdust at the source. So the more you restrict that flow the less sawdust it collects at the source. Breathing fine dust is not a good thing but at some point you get diminishing return on investment by restricting your air flow.

Electrical cords are often molded with barely passable connections on appliances - you ever check how warm your kettle cord end gets by the time the water boils? I’ve encountered plenty that I would consider concerning - but those are pulling a pretty constant near-max circuit current for a few minutes.

The great thing about electrical cords is that they are usually about the easiest thing to replace & upgrade with better plugs & more secure internal wiring connectors if you really want to & know how to do wiring.

Isn’t the HEPA bag redundant if used with a HEPA filter?