Hey folks,

Just built an enclosure for my Shapeoko 5 pro!

Figured I’d share since I gathered much of my design inspiration from this community.

I’m no design expert. Lots of my decisions felt over engineered. Several mistakes were made. A few minor details remain unfinished. Overall I’m happy with the results ![]()

Main design is fairly straight forward. Torsion box base, 2x2 frame, 3/4 ply outer. Big ol plexiglass window on a gas strut mounted front door.

Some led strips mounted to the top frame, angled towards the back of the enclosure.

Dust collection 2 stage w/ Fein turbo

Total dimensions L 45 x W 70 x H 38 (inches)

It all sits on top of my old workbench/outfeed table.

*Fresh resurface of the spoil boards. Trammed n’ ready to go.

Noise reduction was my primary goal. Not going ‘sound proof’ or anything, just enough to remain on good terms with my neighbors.

I chose Steico floor underlayment for sound absorption. I liked the green color, and it was thin. Is it helping compared to just plain plywood? I have no idea. Feels like I wasted my time and money here. At least it looks nice.

Full access to the machine for maintenance and project indexing via doors on the sides and the back. All 3 doors are attached with a lower hinge that lets them swing down.

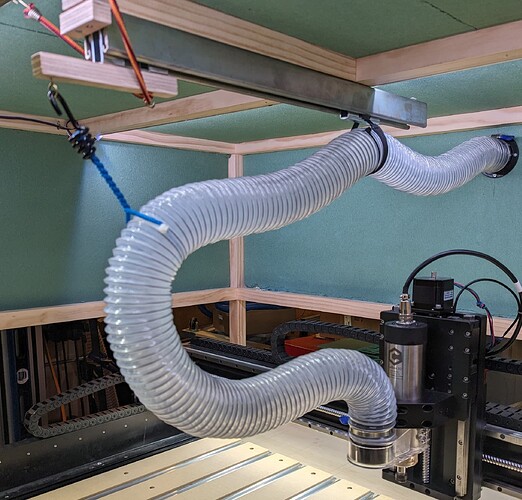

I spent quite a lot of time dialing in this hose hanging contraption. I wanted to prevent the hose and spindle from colliding, and I wanted the hose to exit from the rear of the enclosure. I decided to use strut trolleys to move the hose in relation to the spindle. The red/orange bungee cord is tensioned to allow the hose to retreat backwards as needed, then pull the hose towards the front of the enclosure as the spindle nears. The blue bungee is to assist just that extra little bit when the spindle is passing directly under the front of the machine.

Works like a charm!

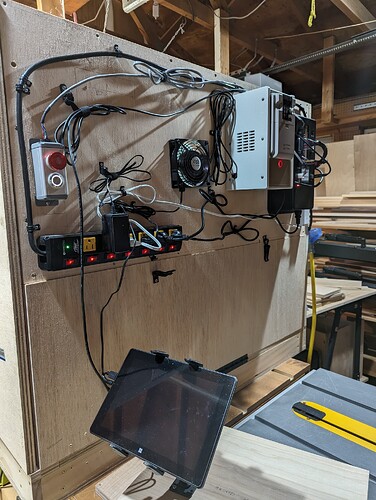

Lastly I’ve directed all cables n’ such to the outer right of the enclosure. I’ll clean this up another day.

I ran the VFD spindle cord through the right side of the cable track so I could have everything on one side of the enclosure. Having that vfd spindle cable so short and hardwired to the box is a pain in the butt.

Found a power strip with individual buttons for each outlet.

(You can see my table saw now needs a new home, lol)

Thanks for checking it out.

Open to any feedback ![]()